Multiple channel micropump apparatus and drive method

A driving method and technology of micro-pumps, which are applied in the directions of micro-structure devices, micro-structure devices composed of deformable elements, pumps, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0032] Specific examples are given below to illustrate the beneficial effects of specific embodiments of the present invention:

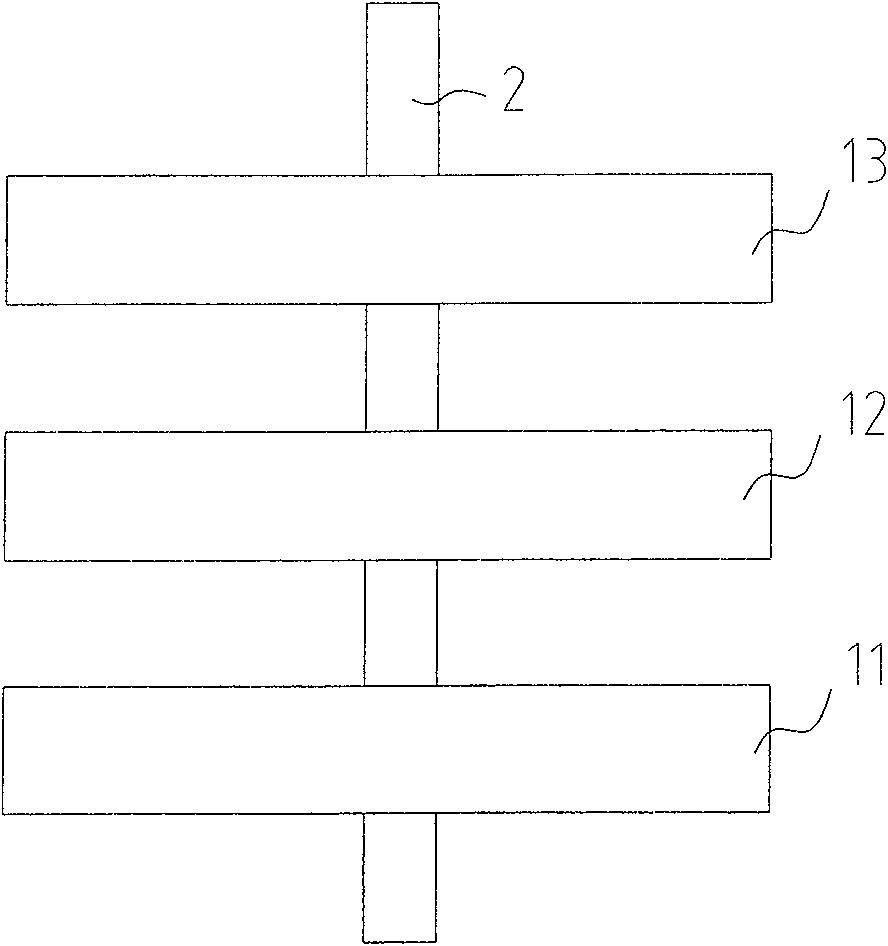

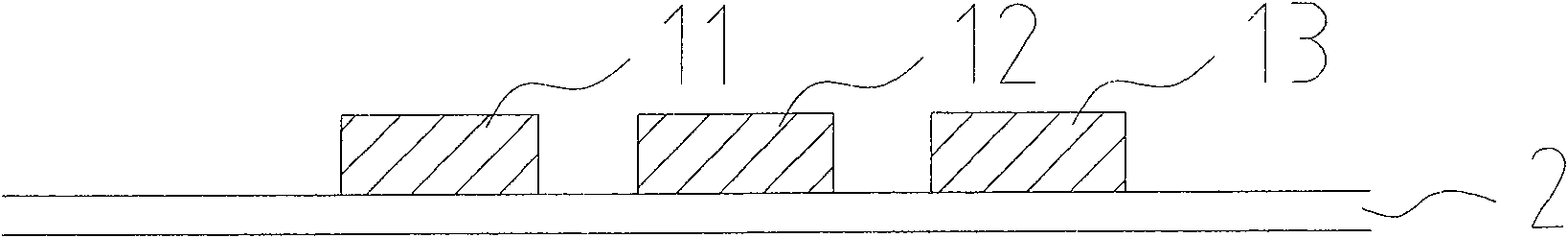

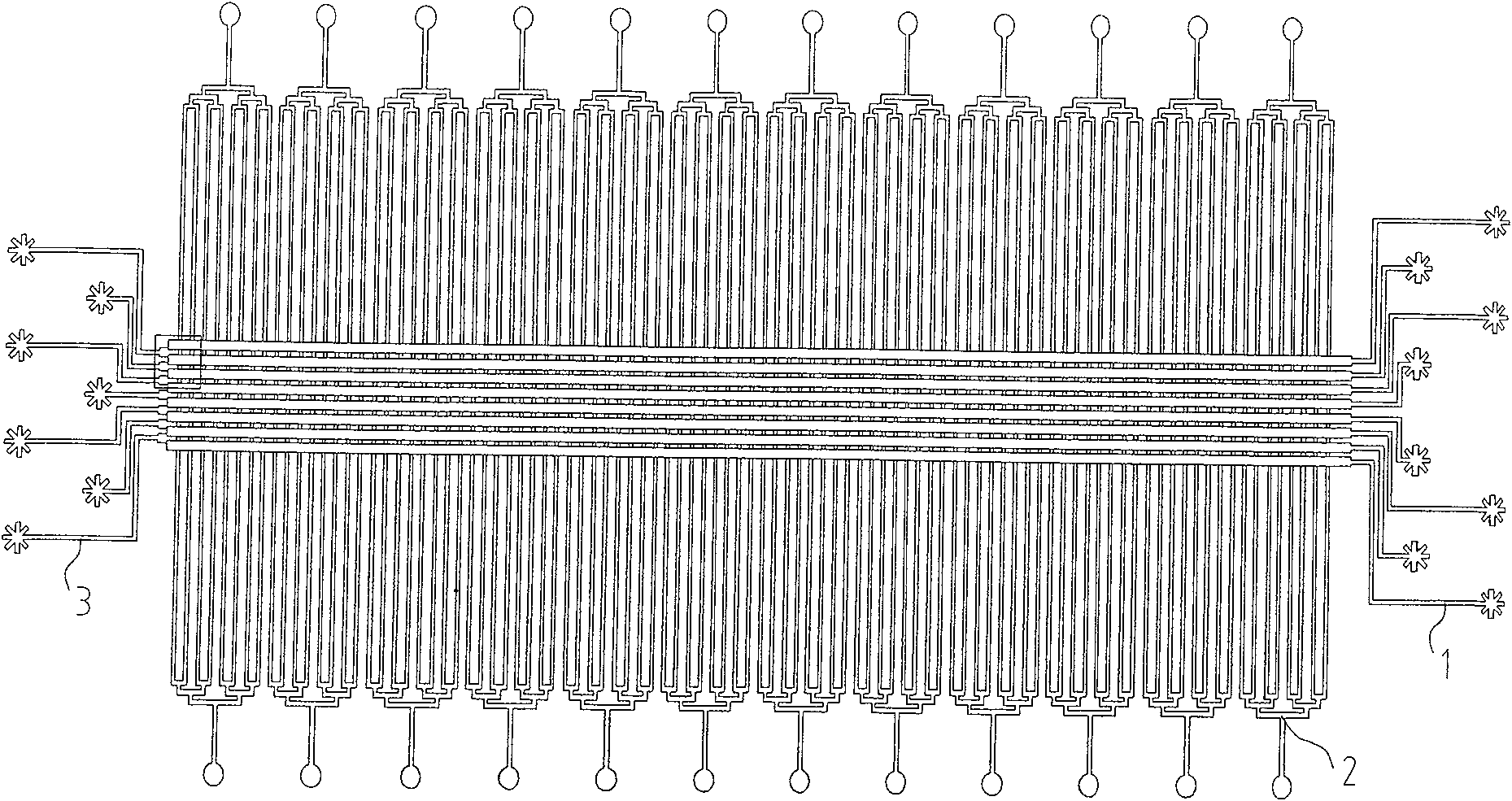

[0033] 1. 96-channel micropump with improved structure

[0034] The micropump is composed of three layers of silica gel: the delivery microchannel for transporting the liquid is placed between two layers of extruded microchannels, the delivery microchannel is 20 microns deep and 100 microns wide, and the flow direction is arranged in the direction of the extruded microchannels They are perpendicular to each other; the upper and lower layers of silica gel are extruded micro-channels containing 5 and 7 respectively. The extruded micro-channels are 40 microns deep and 100 microns wide, and the extruded micro-channels are arranged in parallel with each other. , and the upper and lower extruded microchannels are arranged in a staggered and partially overlapping manner, and the width of the overlapping part is 25 microns. Driven by the control of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com