Power regenerating watercraft hydraulic pressure propulsion method and apparatus

A propulsion device and energy recovery technology, applied in the direction of non-mechanical gear transmission, etc., to achieve the effect of large power-to-weight ratio of equipment, high mobility, and flexible cabin layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

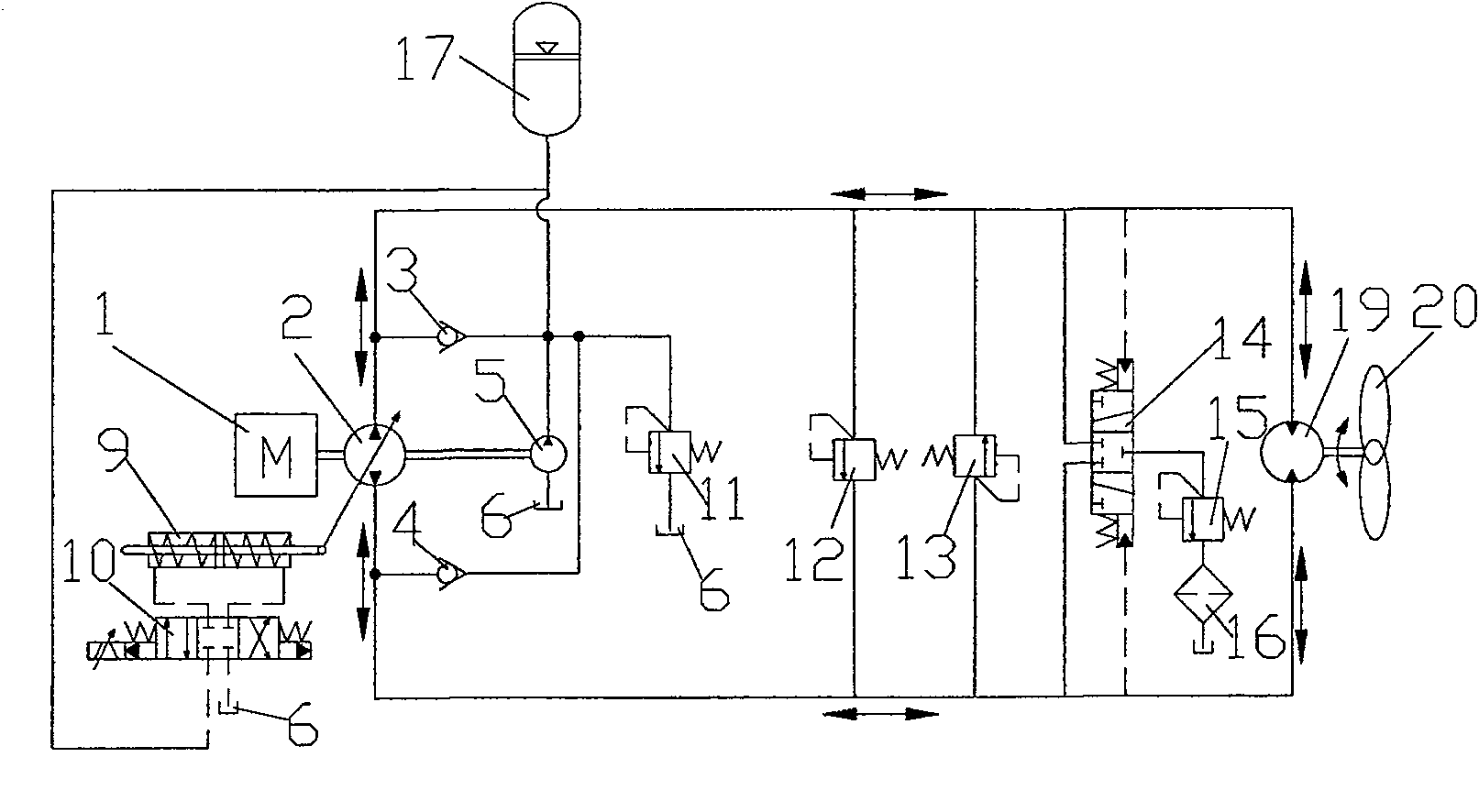

[0022] figure 1 When the system is working normally, the first two-way quantitative pump-motor 19 works under the motor condition, and the first ship main engine 1 drives the first two-way variable variable pump 2 to supply oil to the first two-way quantitative pump-motor 19 to drive the first The propeller 20 rotates to provide driving force for the ship. Driven by the first ship main engine 1, the first fuel pump 5 sucks oil from the oil tank 6, supplies oil to the low-pressure side of the system through the first check valve 3 or the second check valve 4, and stabilizes the pressure through the first accumulator 17 Afterwards, the first supplementary oil pump 5 provides control oil for the first servo cylinder 9 and the first servo valve 10 while supplying oil to the low pressure side of the system. The variable mechanism of the first two-way variable pump 2 is composed of the first servo cylinder 9 and the first The servo valve 10 is controlled, and the first overflow val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com