Mask and method for forming polycrystalline silicon layer using the same

A polysilicon layer and mask technology, applied in the field of masks, can solve problems such as differences in electrical characteristics of polysilicon thin film transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

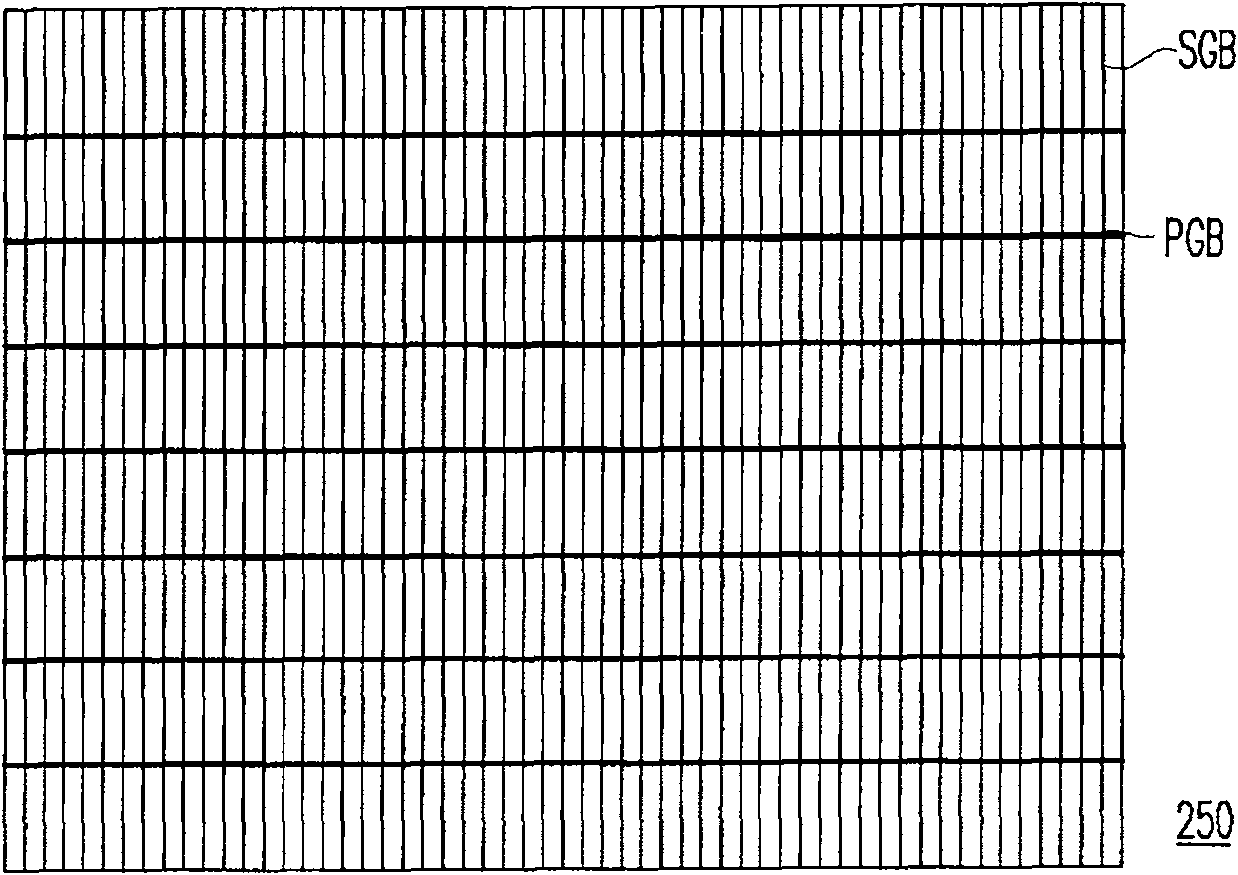

[0020] image 3 is a schematic flowchart of a method for forming a polysilicon layer according to an embodiment of the present invention.

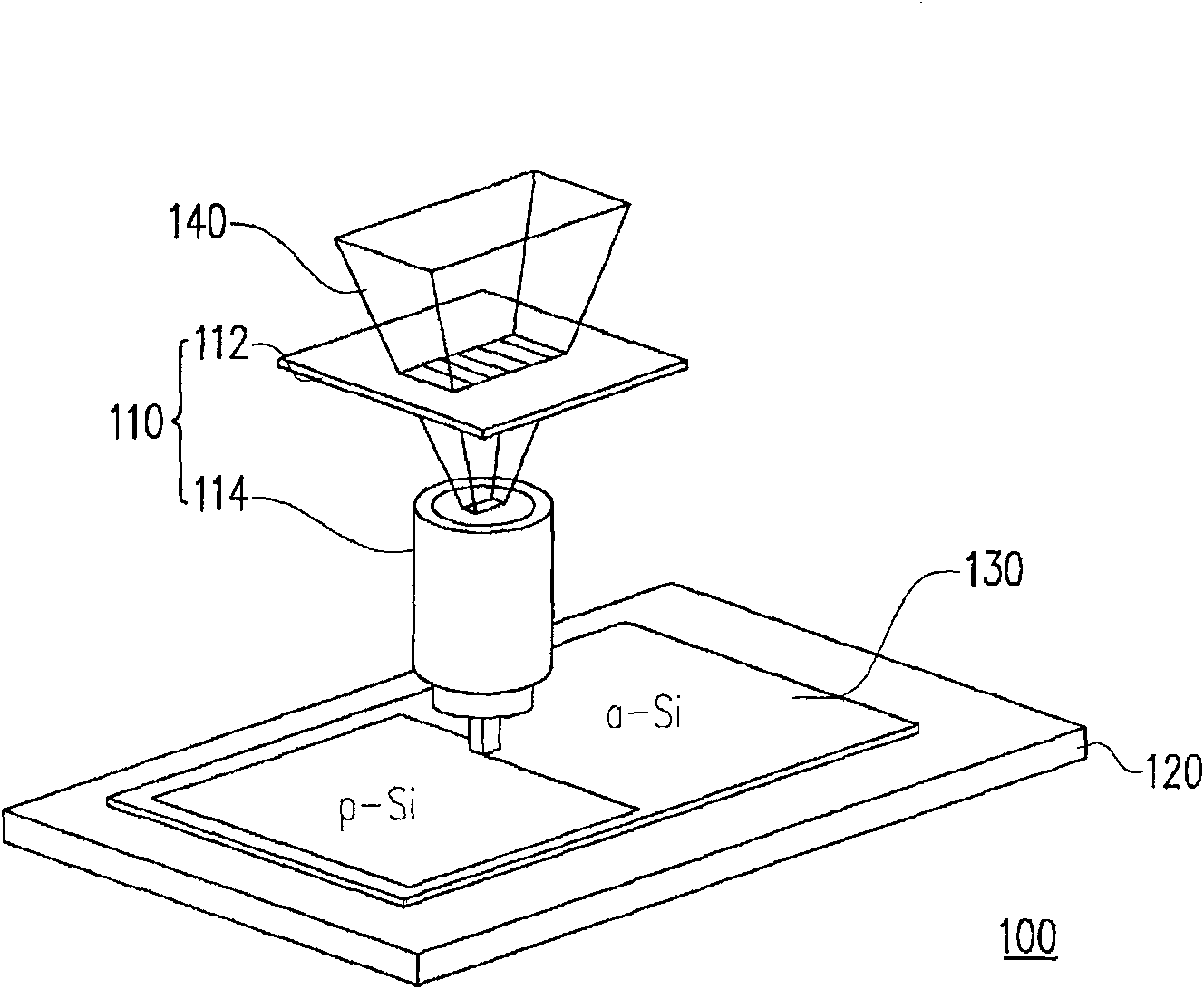

[0021] Please refer to image 3 , firstly, step S300 is performed to form an amorphous silicon layer on the substrate. Then, for example, the substrate formed with the amorphous silicon layer is placed in such as figure 1 Shown is a continuous lateral crystallization laser crystallization device on a substrate stage 120 . Wherein, the material of the substrate is, for example, an inorganic transparent material (such as: glass, quartz, or other suitable materials, or a combination of the above), an organic transparent material (such as: polyolefins, polyols, polyalcohols, polyesters, or combination of the above. In this embodiment, the material of the substrate is glass as an example, but the invention is not limited thereto. The method for forming the amorphous silicon layer is, for example, chemical vapor deposition, inkjet method, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com