Calibration standard

A reference piece, a technology to be calibrated, applied in the direction of electrical components, two-part connection devices, and parts of the connection device, which can solve problems such as errors and non-removal, and achieve the effect of eliminating measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

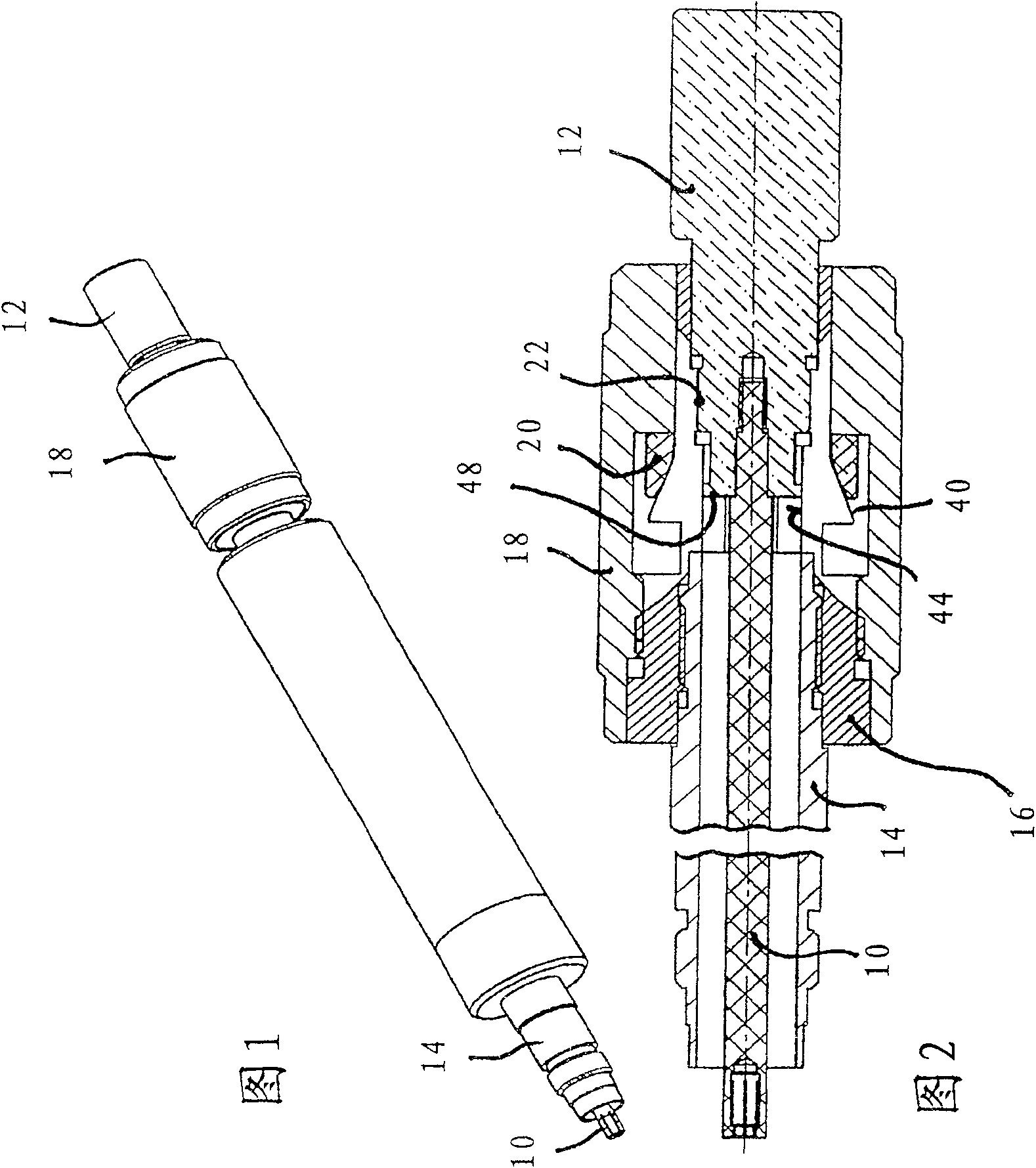

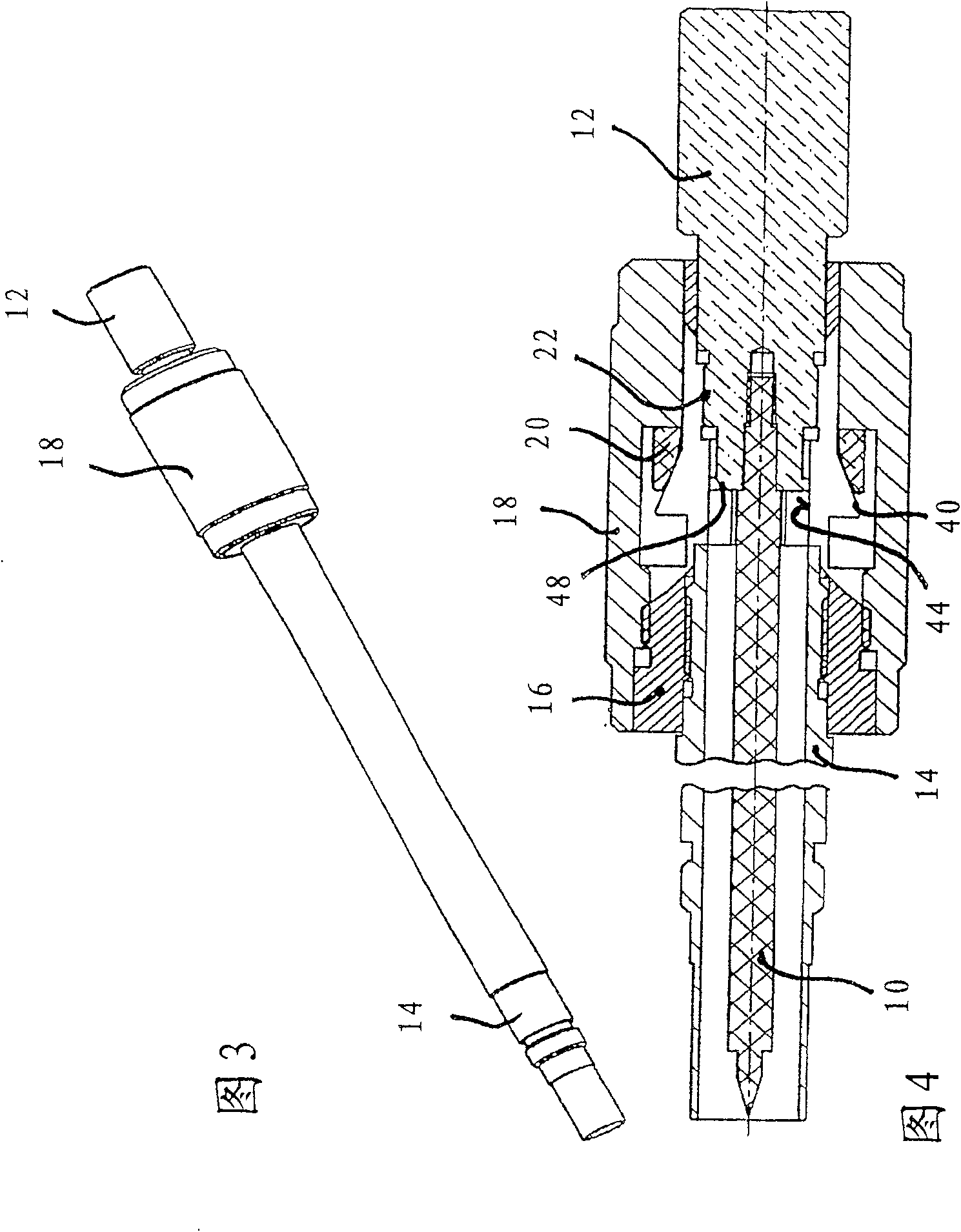

[0030] exist Figure 1 to Figure 4 Illustrate in - according to the present invention as the coaxial socket ( figure 1 and figure 2 ) or coaxial plug ( image 3 and Figure 4 ), the calibration standard is also called "Offset-Short", especially from figure 2 and Figure 4 As can be seen in the figure, it comprises: an inner conductor part 10 with an adjusting screw 12, an outer conductor part 14, a contact bushing 16, a set screw or set or lock nut 18 and a compression ring 20. The outer conductor part 14 and the contact bushing 16 form a fixed unit. Likewise, the inner conductor part 10 and the adjusting screw 12 form a fixed unit, wherein in the illustrated embodiment the inner conductor part 10 and the adjusting screw 12 are screwed together. The inner conductor part 10 is engaged at 22 by a thread (at figure 2 and Figure 4 Not shown in the cross-sectional view) between the external thread on the adjustment screw 12 and the internal thread on the contact bush 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com