Electrode wire lead-out structure of field emission display

An electrode wire and lead-out structure technology, which is applied in the field of field emission displays, can solve the problems of affecting the vacuum environment, air leakage from the close contact of the substrate, and unfavorable electrode wire configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, technical content of the present invention is described in detail:

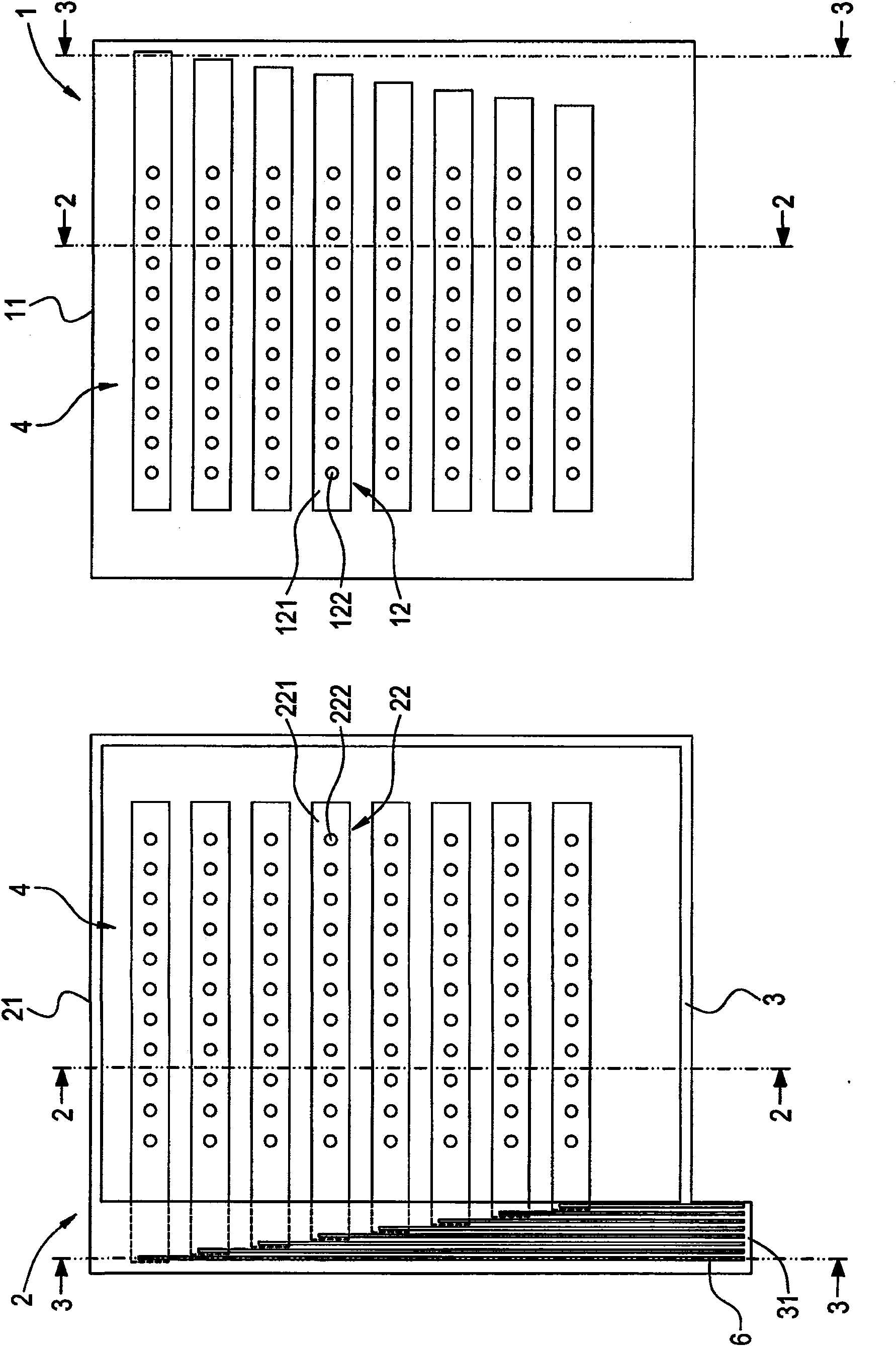

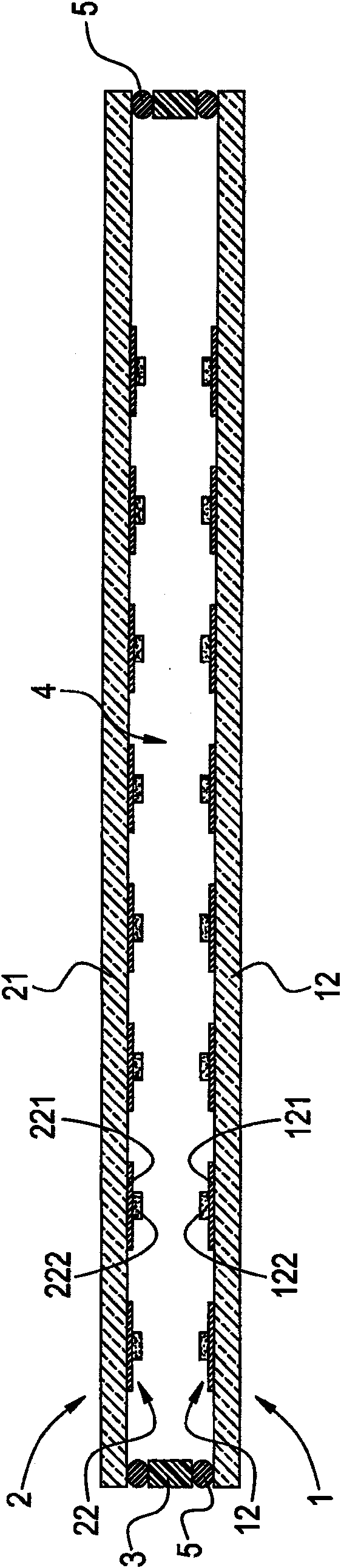

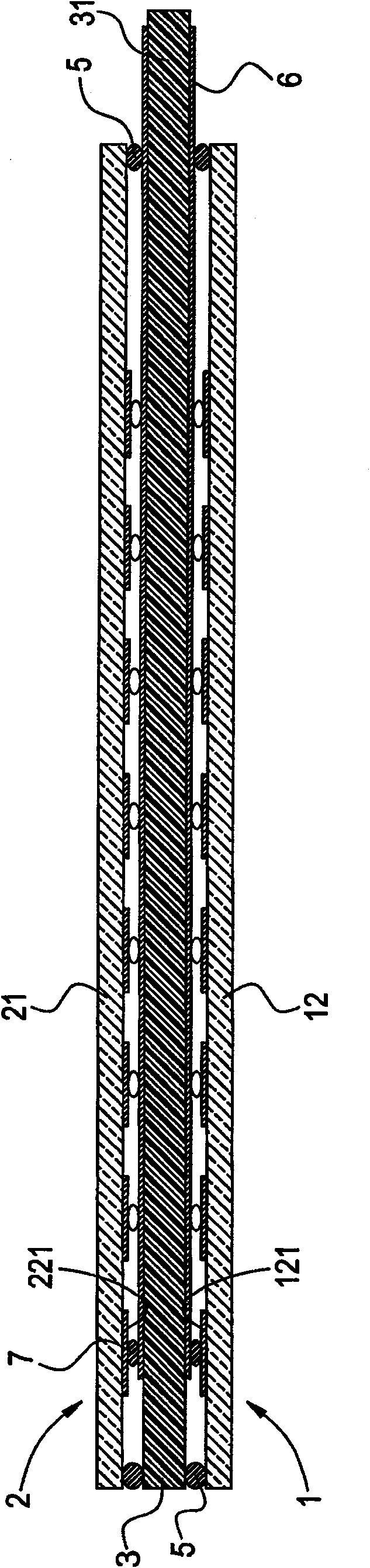

[0022] figure 1 It is a front view of the cathode and anode plates of the present invention. As shown in the figure, the field emission display structure of the present invention mainly includes a cathode plate 1, an anode plate 2 and a packaging frame 3, and the cathode plate 1 and the anode plate 2 are combined correspondingly; wherein the cathode plate 1 has a cathode substrate 11, and the cathode substrate 11 is provided with There are a plurality of cathode units 12, each cathode unit 12 further includes a cathode electrode layer 121 disposed on the cathode substrate 11, a plurality of cathode electron emission sources 122 are arranged on the cathode electrode layer 121, and each cathode electron emission source 122 is arranged at intervals, used to release free electrons. The anode plate 2 has an anode substrate 21, and an anode unit 22 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com