Rotor for electric generator

A generator and rotor technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as large space and thick insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

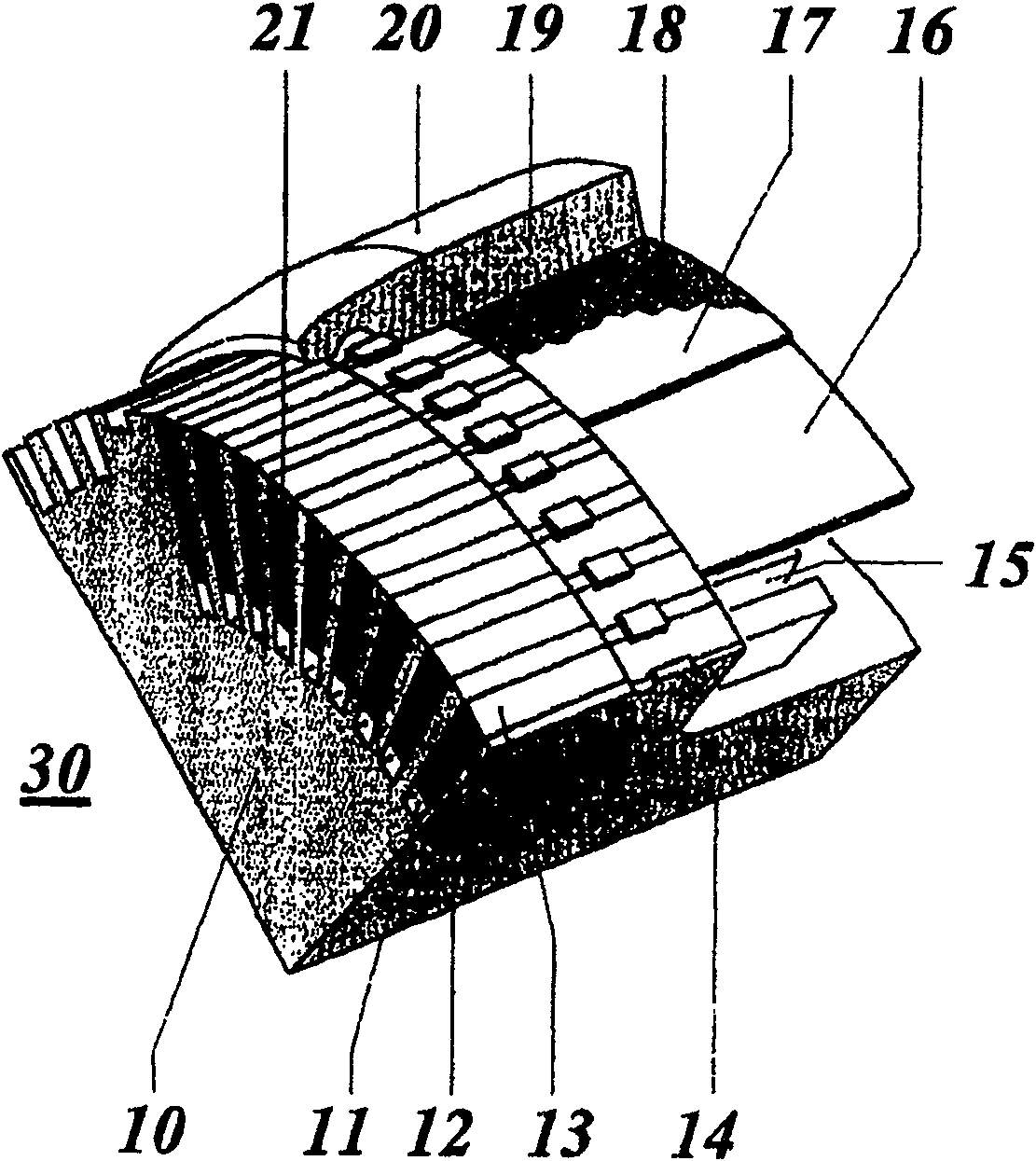

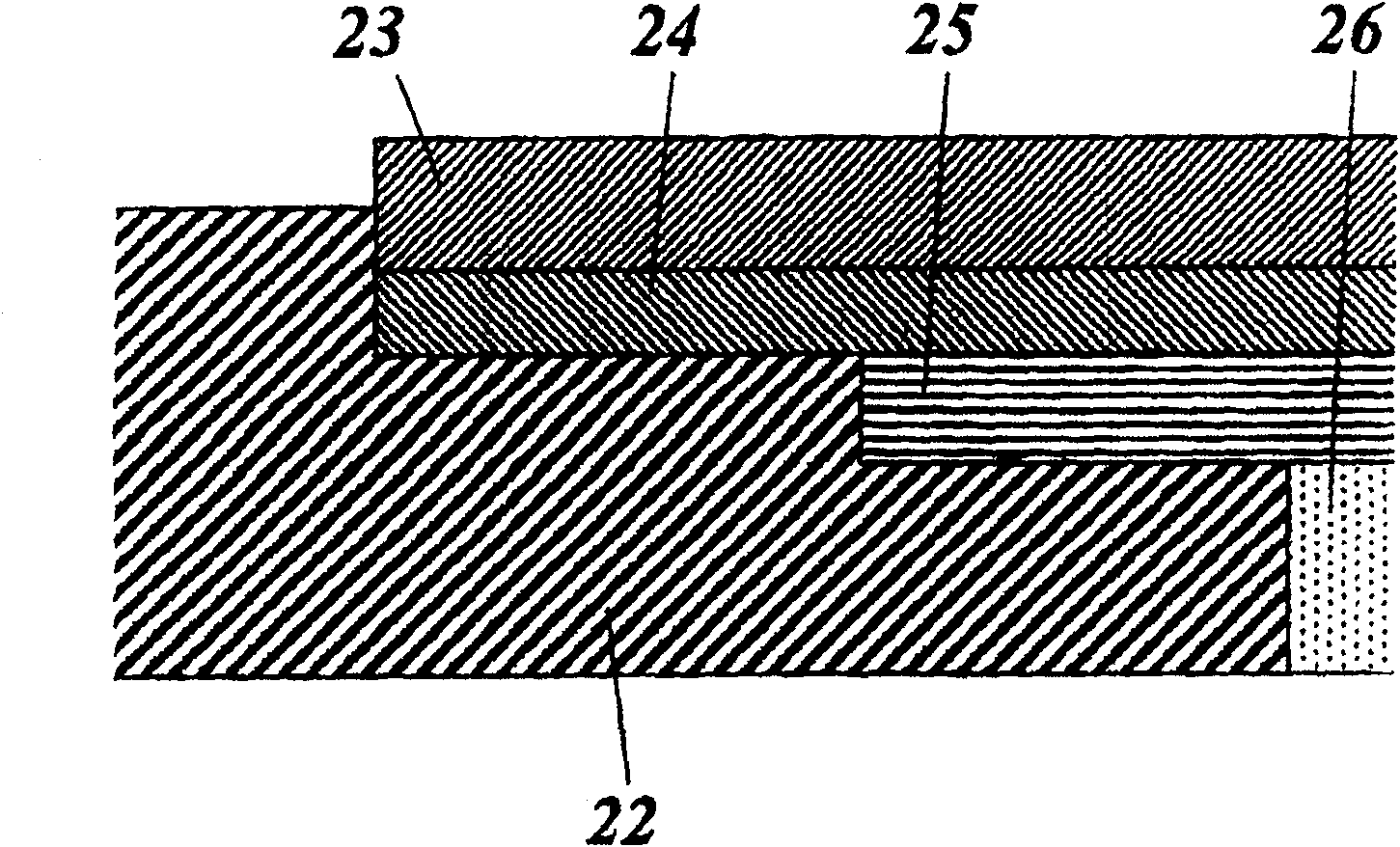

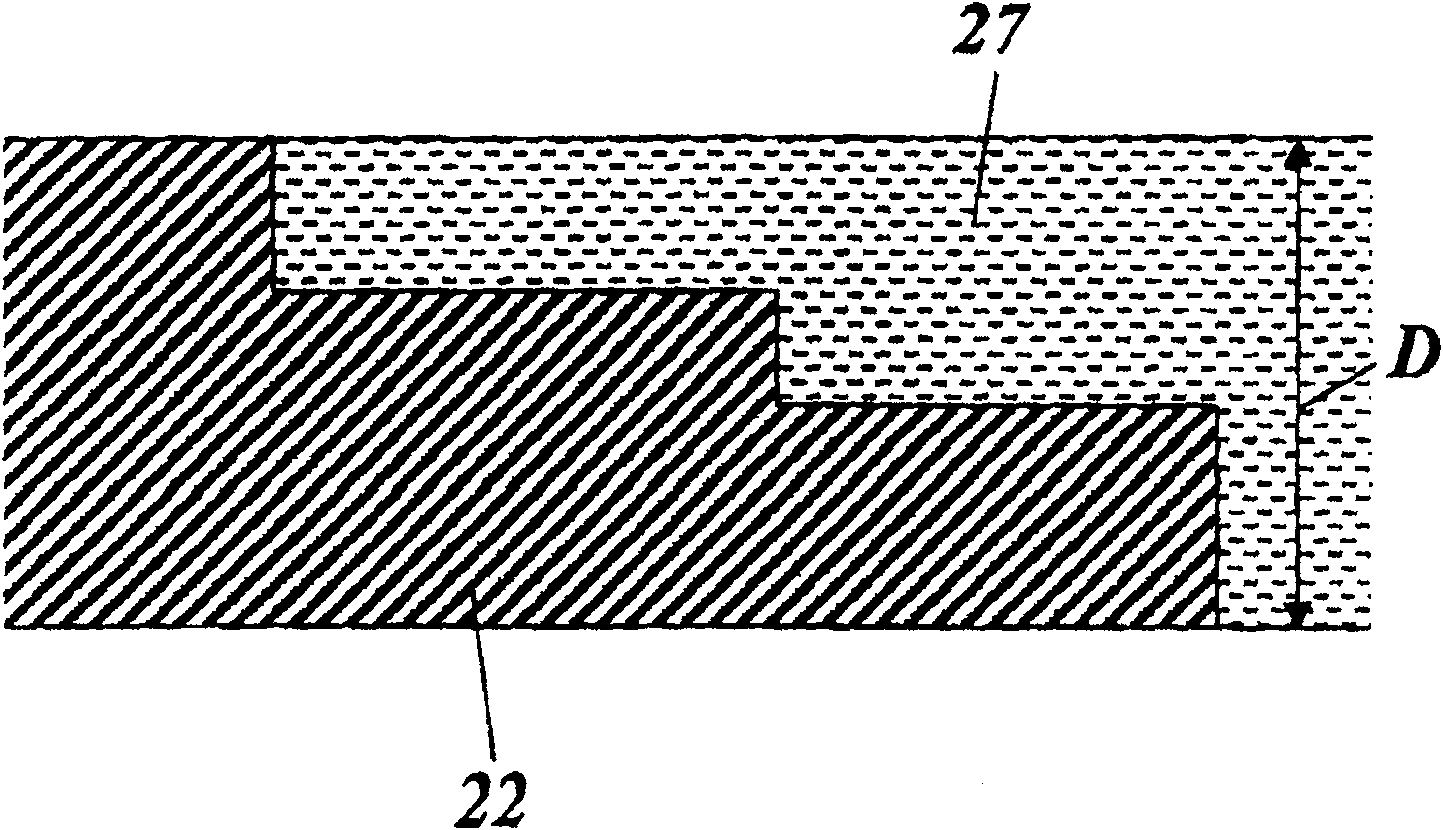

[0025] exist image 3 in a similar figure 2 The illustration shows the transition from an axially stepped cover channel 22 to a radially rigid cover insulating element 27 of almost the same thickness D according to a preferred embodiment of the invention. Figure 4 with a similar figure 1 A view of the rotor 30' according to a preferred embodiment of the invention is shown. The cover insulation section 27 connected in a stepped manner on the cover channel 22 is located here directly below the cover ring 19 of the rotor cover 20 , that is to say without an intervening protective cover plate. Instead of the cover insulating section 27 it is also possible to use a one-piece slotted cover insulating ring.

[0026] The cover insulating element 27 is formed, for example, as a half shell. They have the following features and advantages:

[0027] ●The insulation section of the cover has high radial rigidity.

[0028] ●The insulation section of the cover has high tangential rigi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com