Inflatable tyre

A technology of pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve problems such as difficulties and achieve the effects of suppressing partial wear, good off-road driving performance, and reducing impact noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

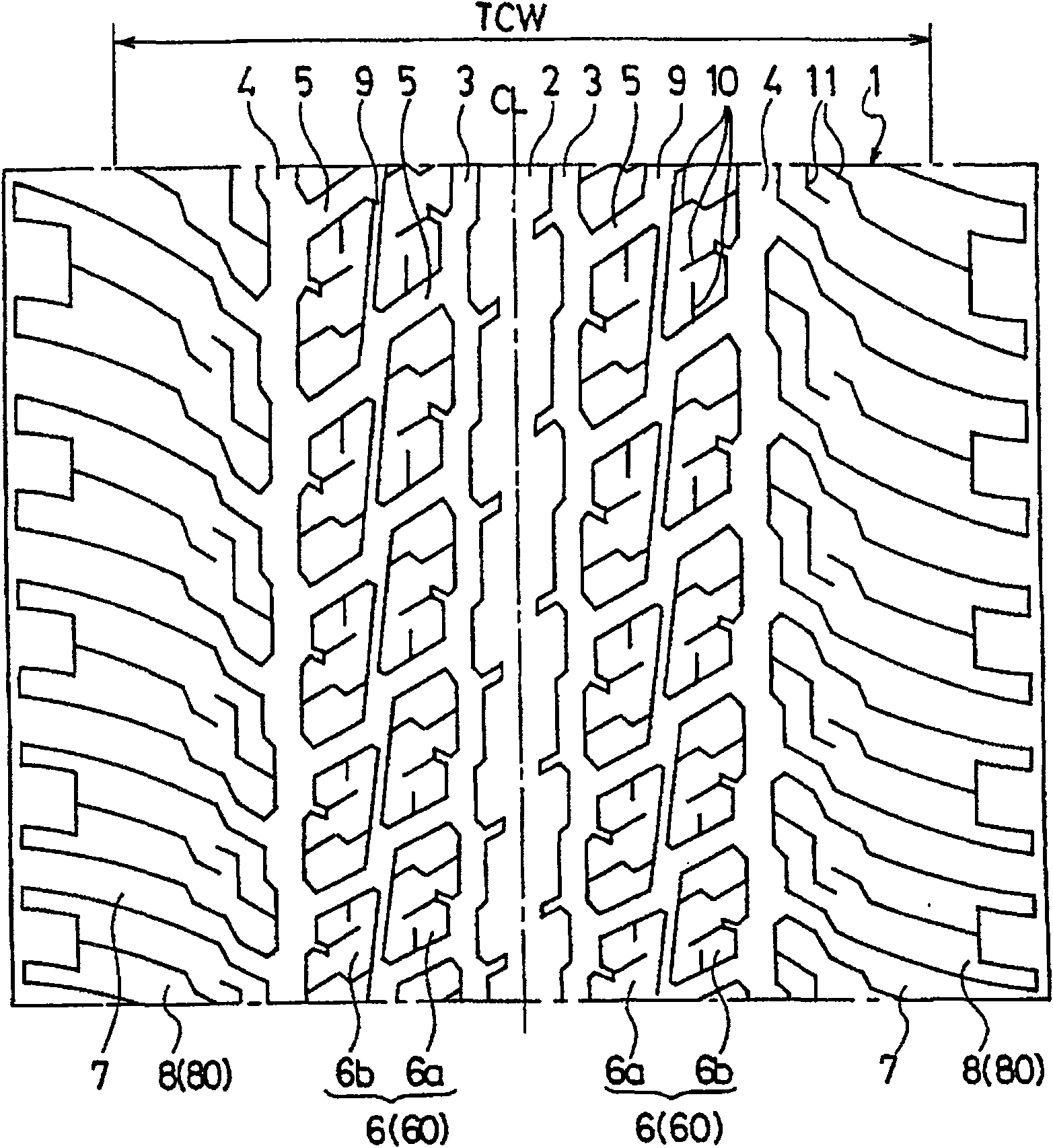

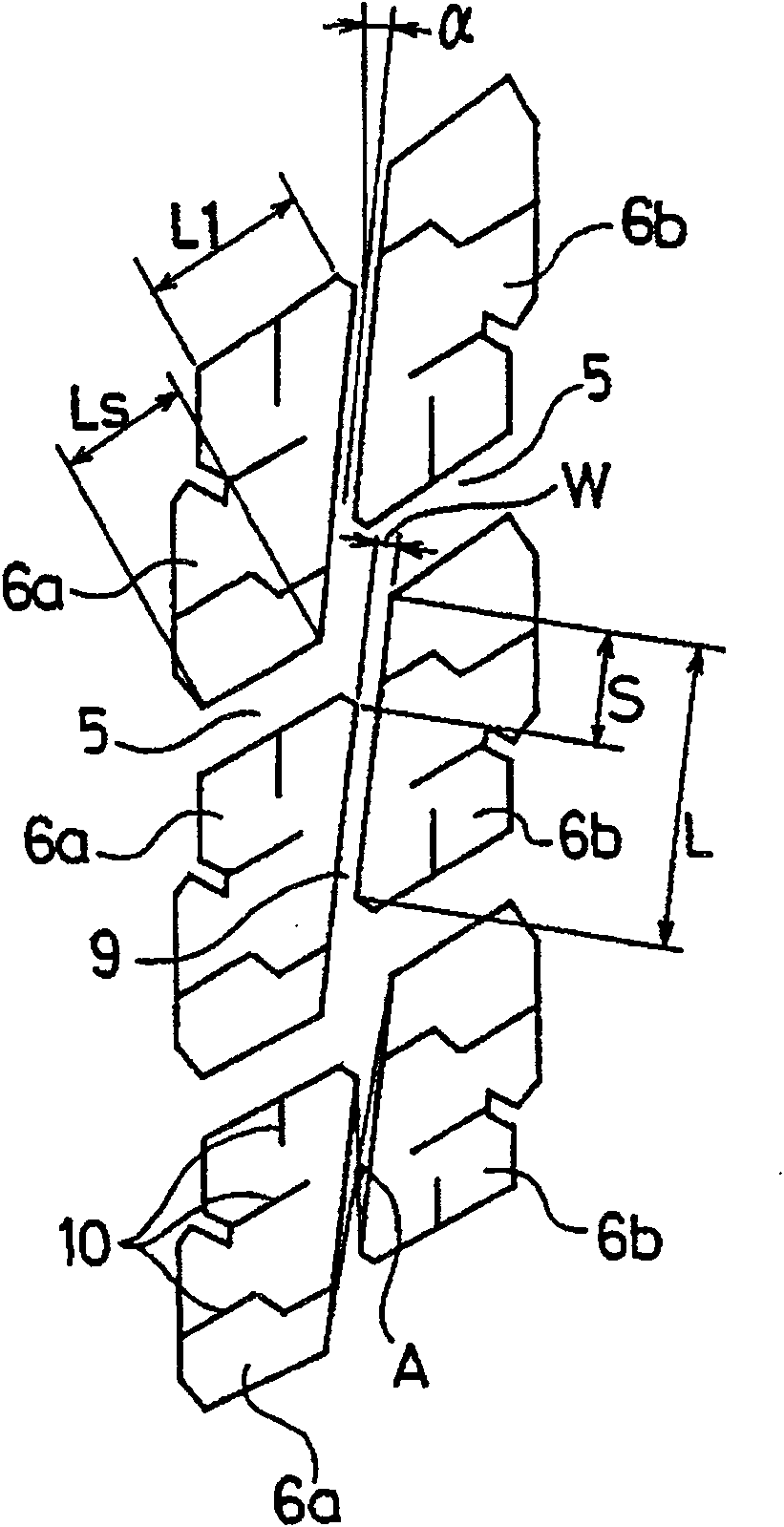

[0028]The tires of Comparative Examples 1 to 3 and Examples 1 to 7 were manufactured respectively, and the tire size was 285 / 60R18. A block row consisting of a plurality of block portions consisting of two main grooves zigzagging on both sides of the flat portion and extending in the tire circumferential direction, and a plurality of lug grooves connecting these main grooves Each block of the block row is divided into a central side block portion and an outer block portion by thin grooves extending in the tire circumferential direction, and these central side block portions and outer block portions are arranged to face The shorter block side facing the pattern groove is relatively staggered along the extension direction of the thin groove, and the ratio (%) of the staggered amount S to the length L of the block side, the inclination angle α (° ), the ratio (%) of the groove width W of the narrow groove to the ground width TCW, and the ratio (%) of the block side length Ls to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com