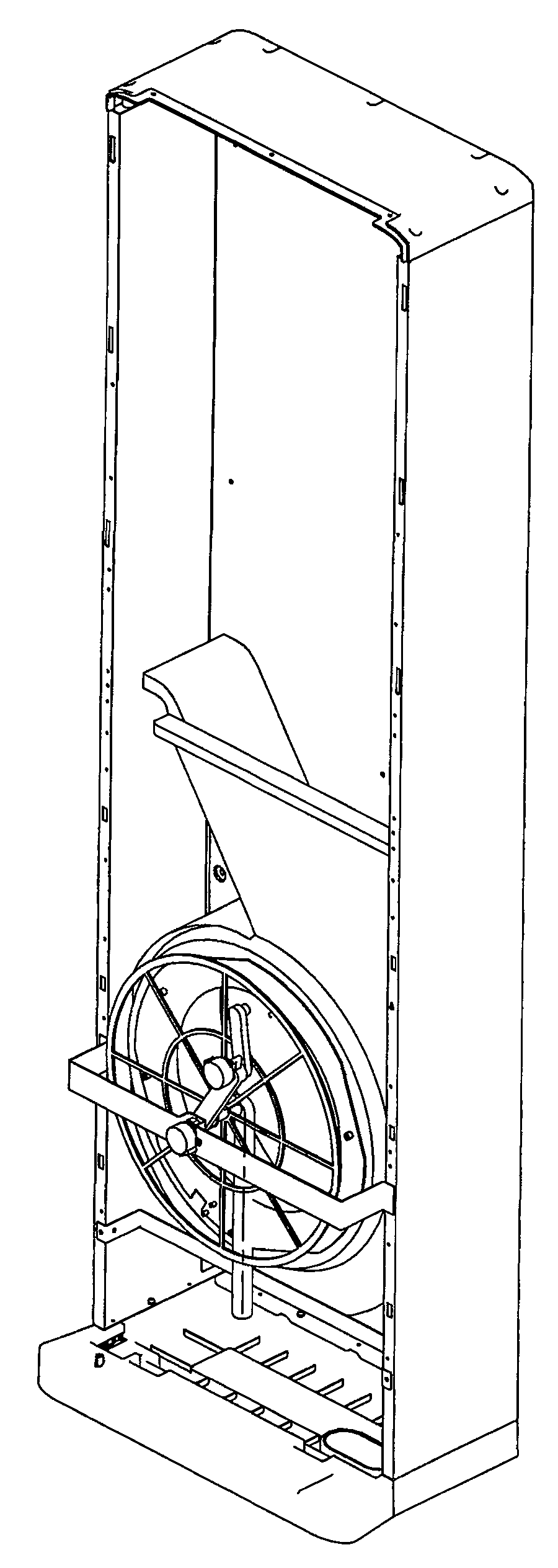

Separate floor type air conditioner filtering net automatic cleaning device

An automatic cleaning and filter technology, applied in the fields of dispersed particle filtration, air conditioning systems, heating methods, etc., can solve problems such as increased energy consumption, inconvenience for users, clogging of filter meshes and ventilation, etc. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

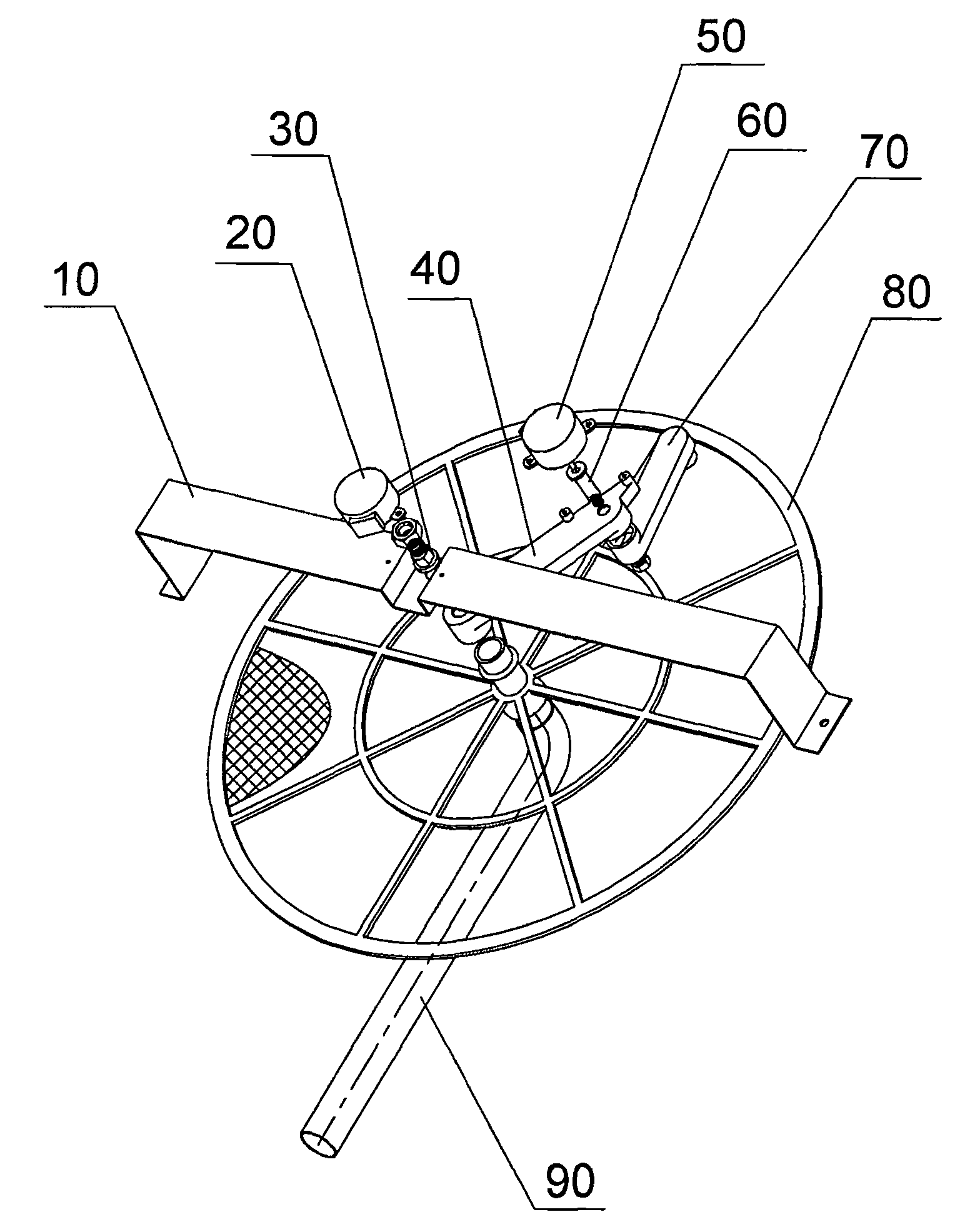

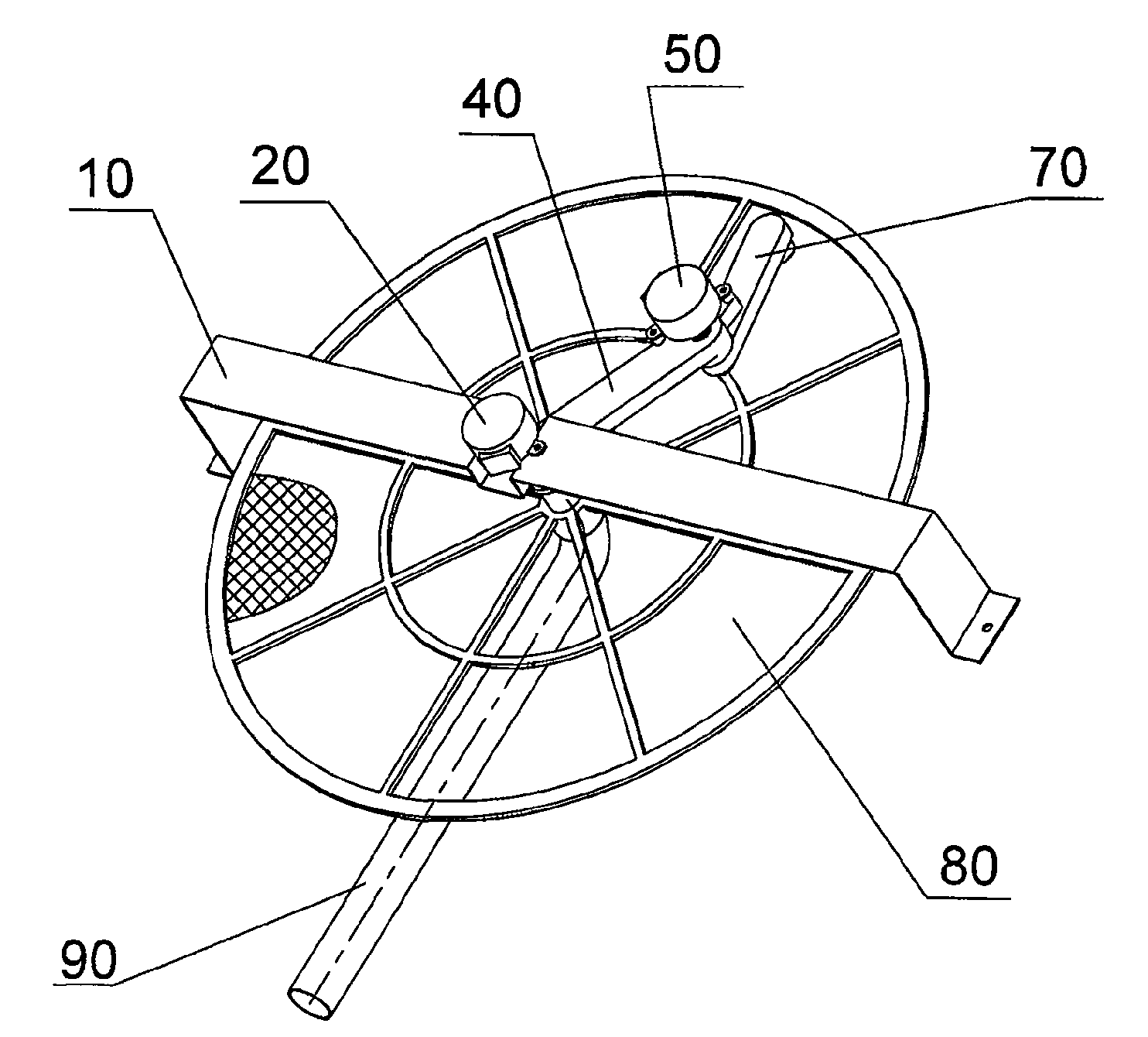

[0020] When the filter screen cleaning button on the air conditioner is connected, the motor a20, the motor b50 and the dust suction device start simultaneously. Driven by the motor a20, the suction pipe a 40 is linked with the suction pipe b, the motor b, and the connector b to make a 360-degree continuous rotation around the center of the motor a20. degree rotation. The two motors rotate at a certain speed, so that the suction nozzle at the end of the suction pipe b70 scans the circular area in front of the filter screen 80, and the purpose of removing dust on the filter screen is achieved by the action of the dust suction device.

Embodiment 2

[0022] When the filter screen cleaning button on the air conditioner is connected, the motor a20, the motor b50 and the dust suction device start simultaneously. Driven by the motor a20, the suction pipe a 40 links with the suction pipe b, the motor b, and the connector b to make a 360-degree reciprocating rotation around the center of the stepping motor a20. rotate. The two motors rotate at a certain speed respectively, so that the suction nozzle at the end of the suction pipe b70 scans the circular area in front of the filter screen 80, and the purpose of removing the accumulated dust on the filter screen is achieved by the action of the dust suction device.

Embodiment 3

[0024] When the filter screen cleaning button on the air conditioner is connected, the motor a20, the motor b50 and the dust suction device start simultaneously. Driven by the motor a20, the suction pipe a40 links with the suction pipe b, the motor b, and the connector b to continuously rotate 360 degrees around the center of the motor a20. The two motors rotate at a certain speed respectively, so that the suction nozzle at the end of the suction pipe b70 scans the circular area in front of the filter screen 80, and the purpose of removing the accumulated dust on the filter screen is achieved by the action of the dust suction device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com