Air-conditioner filtering cleaning device

A technology for cleaning devices and air conditioners, which is applied in air conditioning systems, dispersed particle filtration, space heating and ventilation, etc. It can solve problems such as increased energy consumption, filter mesh blockage and ventilation, and user inconvenience, and achieves low cost, The effect of simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described by citing the embodiments below in conjunction with the accompanying drawings.

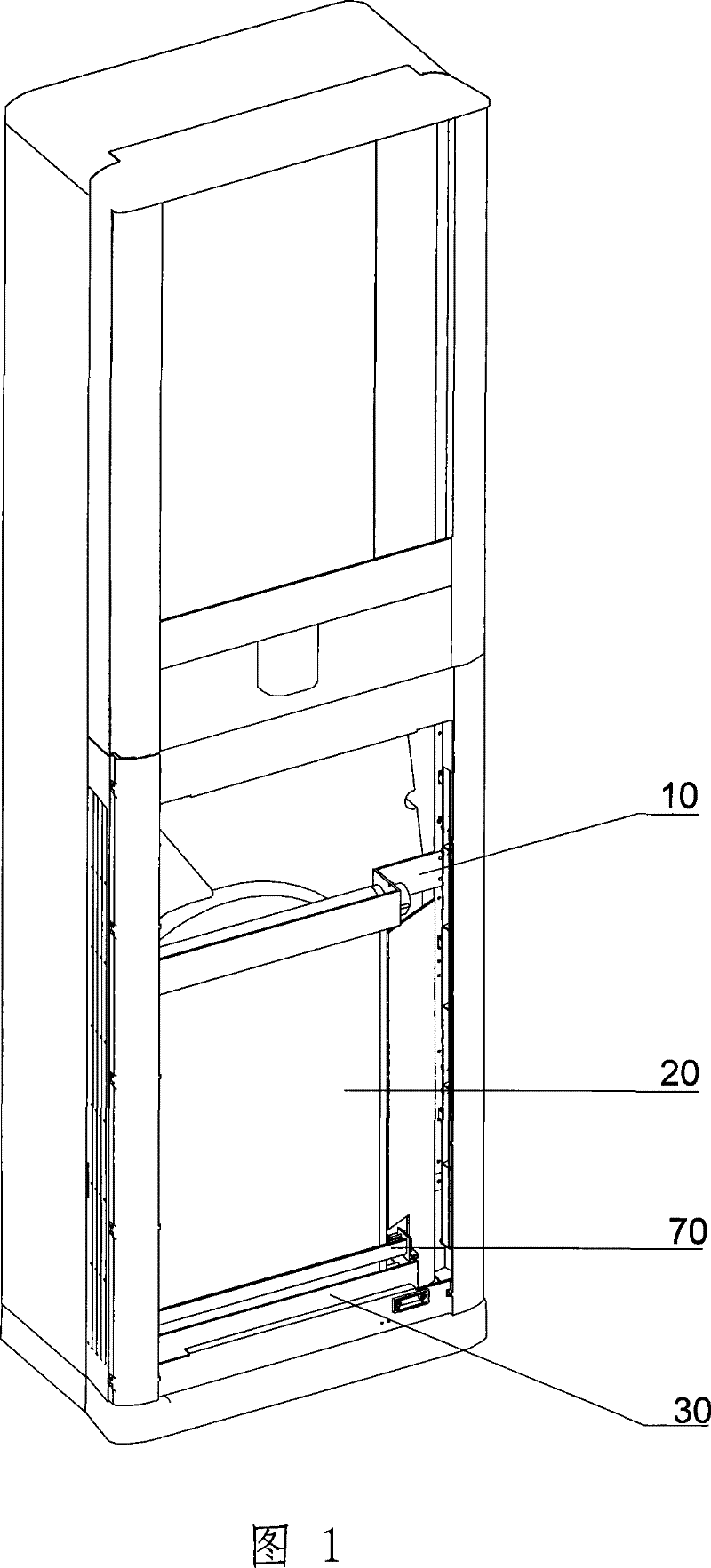

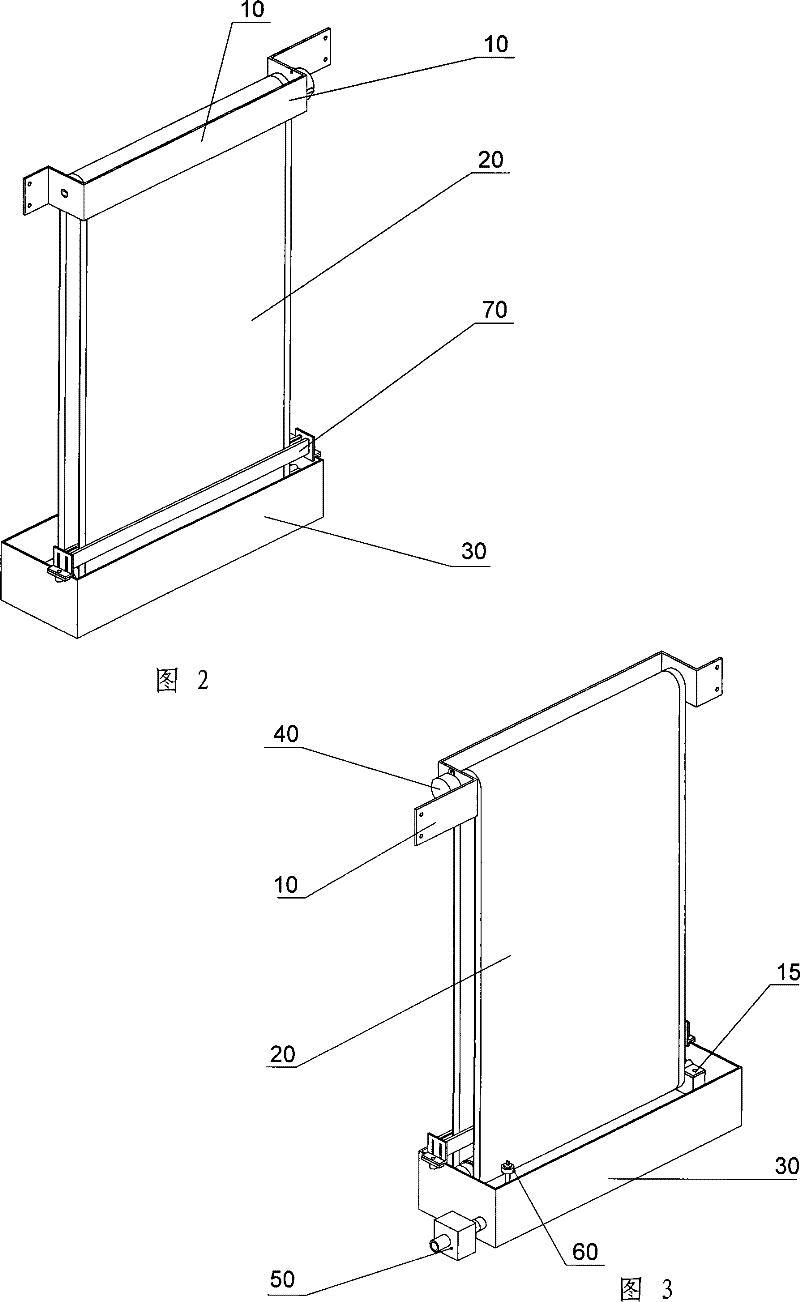

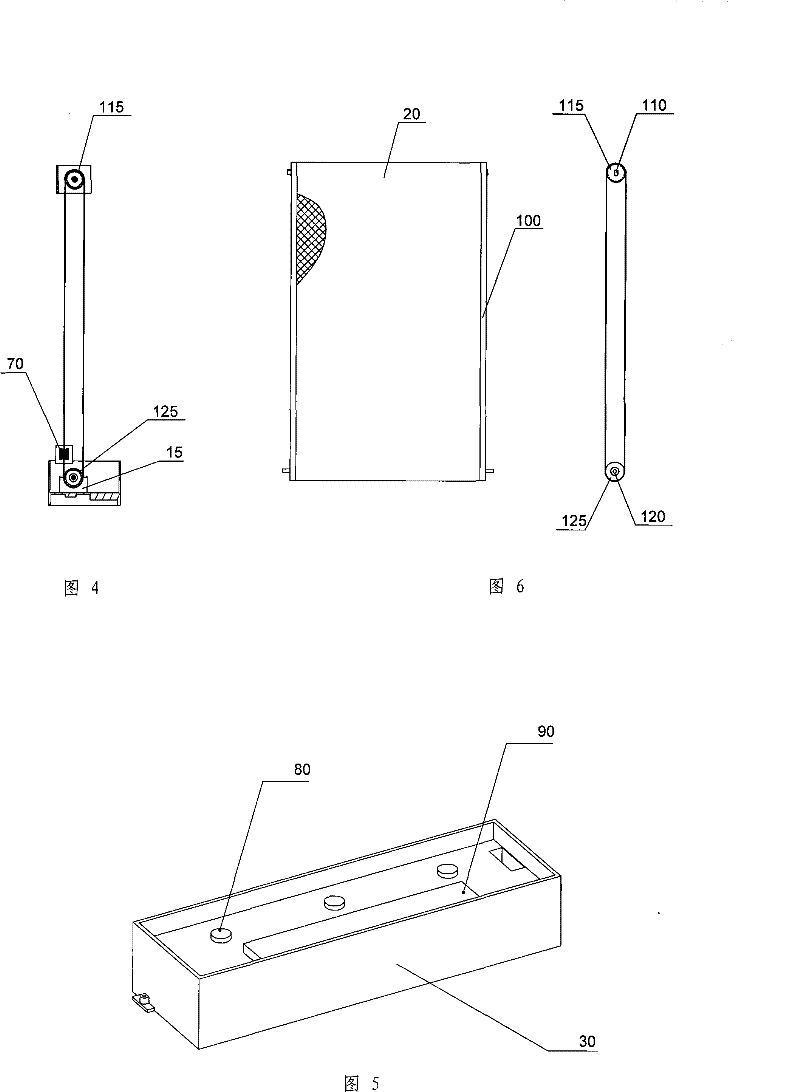

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the filter screen rolling device includes a filter screen transmission connection part, a drive shaft 110 , a drive shaft frame 10 , a synchronous wheel 115 , a motor 40 , a fixed shaft 120 , a fixed shaft frame 15 and a roller 125 .

[0027] The transmission connection part of the filter screen is arranged inside the both sides of the filter screen 20. In this embodiment, the transmission connection part of the filter screen is a synchronous belt 100 structure, such as Figure 7 As shown, or the synchronous belt 100 can only be installed inside one side of the filter screen 20, the synchronous belt can choose one of the equidistant hole structure 100a or the concave-convex tooth structure 100b; the driving shaft 110 is fixed on the air conditioner through the driving shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com