Wheel carrier mechanism capable of rapid folding and expanding

A wheel frame and rapid technology, which is applied to the rescue of motor vehicles, vehicles, chairs for patients or special transportation tools, etc., can solve the problems of inconvenience in carrying and transportation, the casters cannot be folded, and the sliding is easy to occur, and the structure is simple. , Easy to assemble, quick to open and close

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

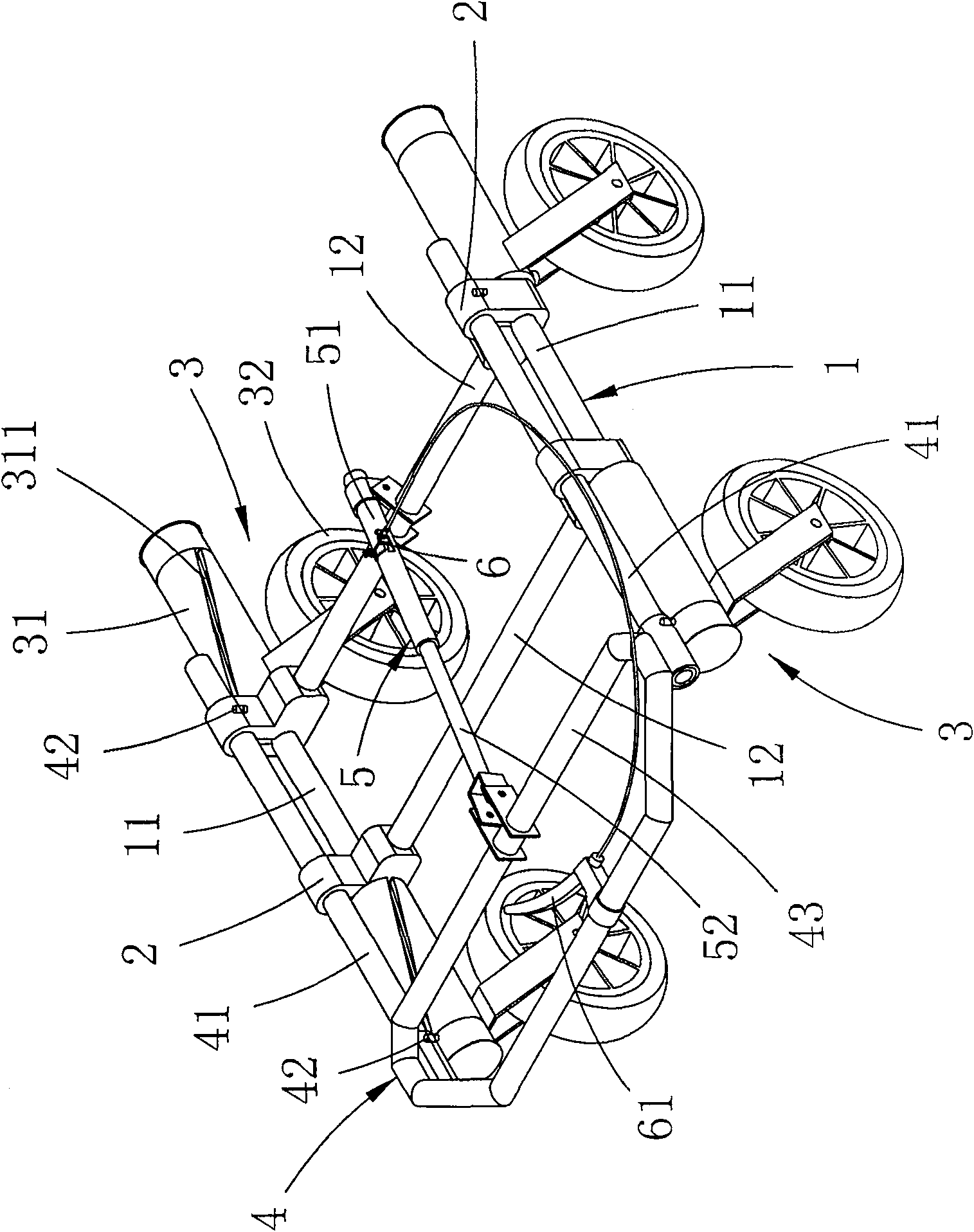

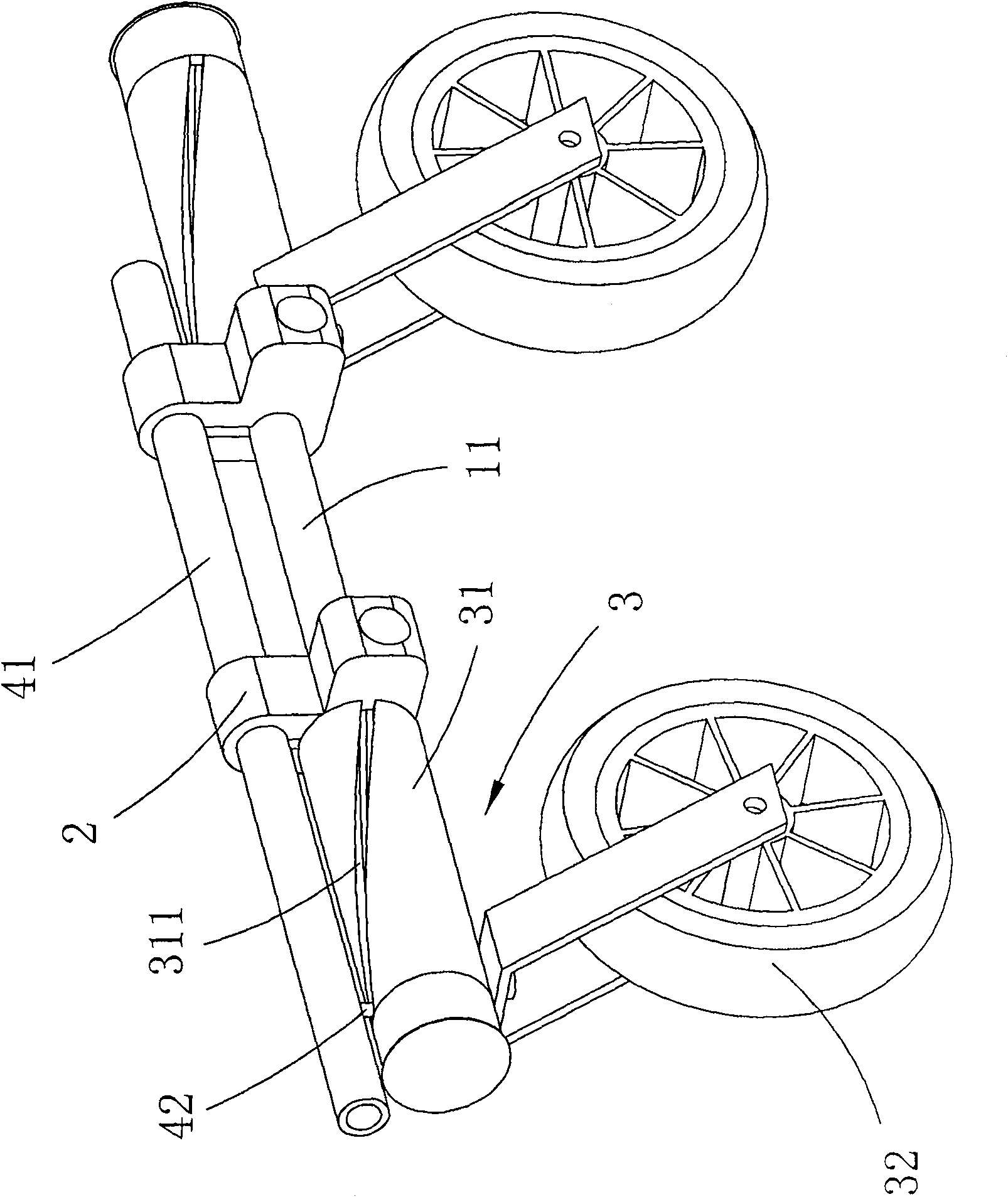

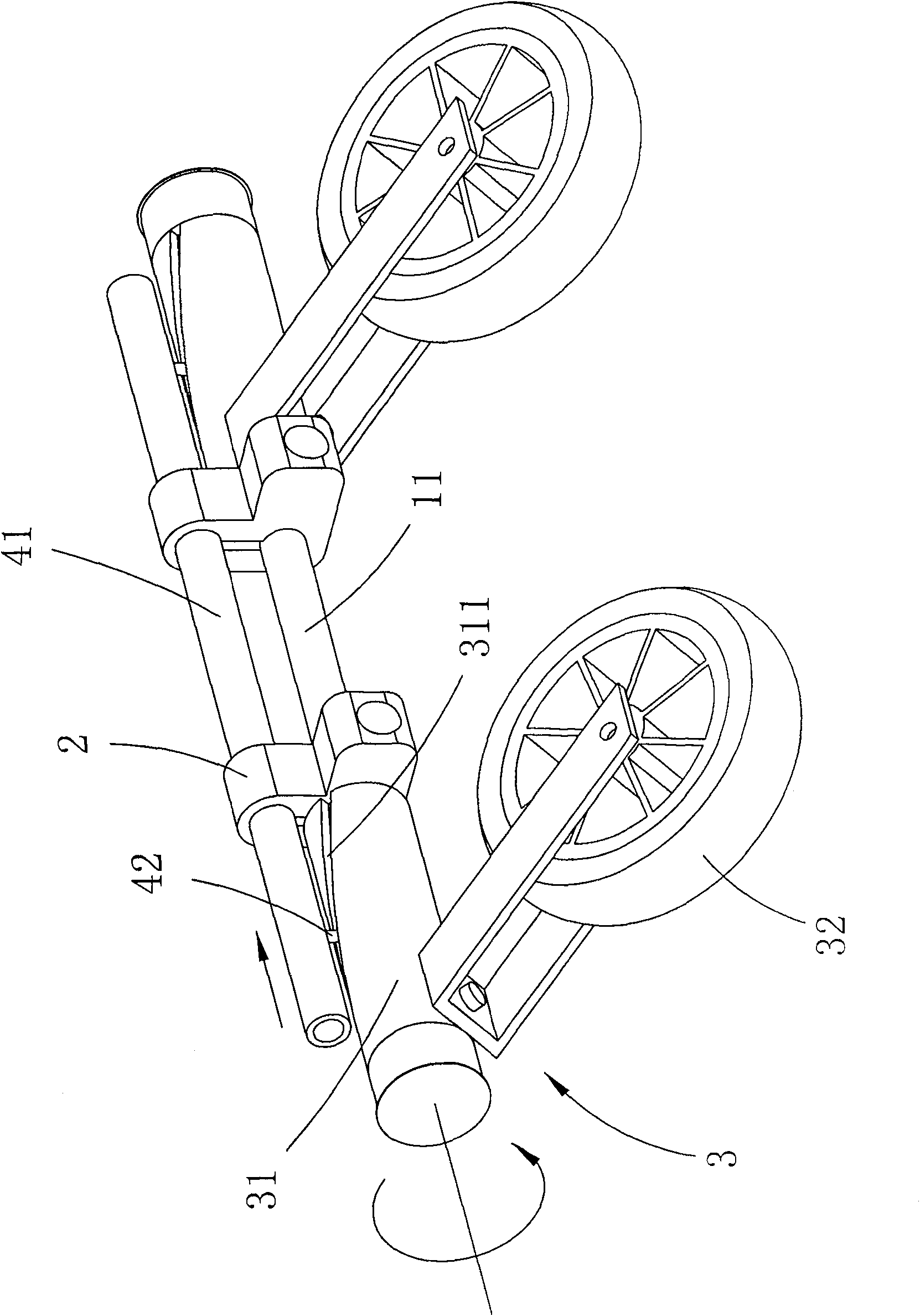

[0033] see figure 1 As shown, it is the rapidly foldable and unfoldable wheel frame mechanism of the present invention, which mainly includes:

[0034] A fixed frame 1, the fixed frame 1 has two fixed rods 11 arranged in parallel, at least one bushing 2 with at least three shaft holes can be sleeved on the two fixed rods 11, and through the described bushings 2 Position the two cross bars 12 between the two fixed bars 11 so that the two fixed bars 11 are stably positioned and parallel to each other;

[0035] Four sets of rotating parts 3, each of the rotating parts 3 is composed of a sleeve 31 and a wheel body 32, and the inner wall of the sleeve 31 is provided with a spiral guide groove 311 , the front end of the guide groove 311 is higher than the rear end, so that the two ends have a height difference and are not equal in height; the sleeves 31 of the four sets of rotating parts 3 are respectively sleeved on the two fixed rods 11 of the fixed frame 1 On the front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com