Tuneable bushing

A shaft sleeve and sleeve technology, applied in the design features of springs/shock absorbers, spring assemblies composed of several springs, springs/shock absorbers, etc., can solve the problems of time-consuming testing and manufacturing and expensive realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

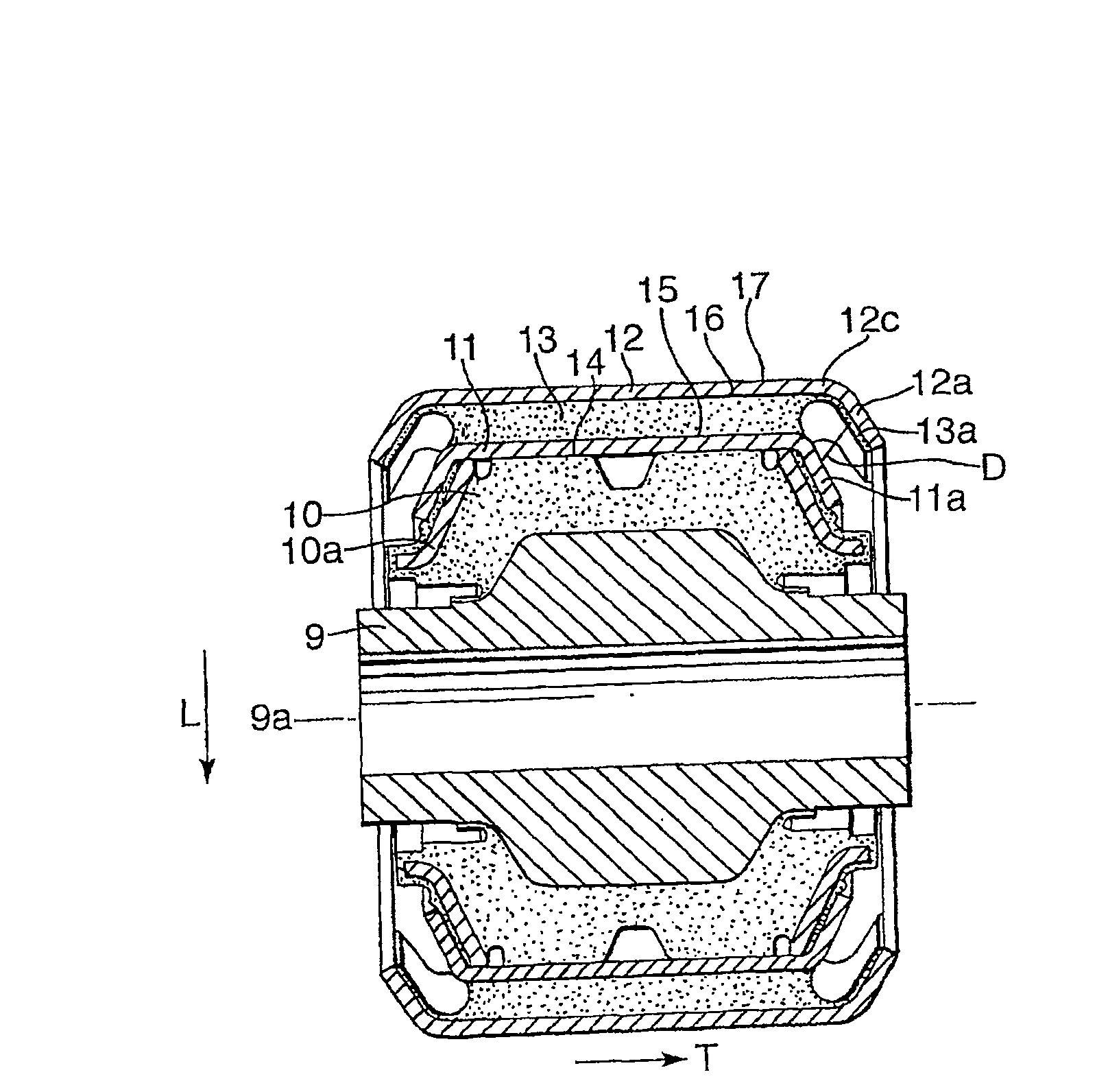

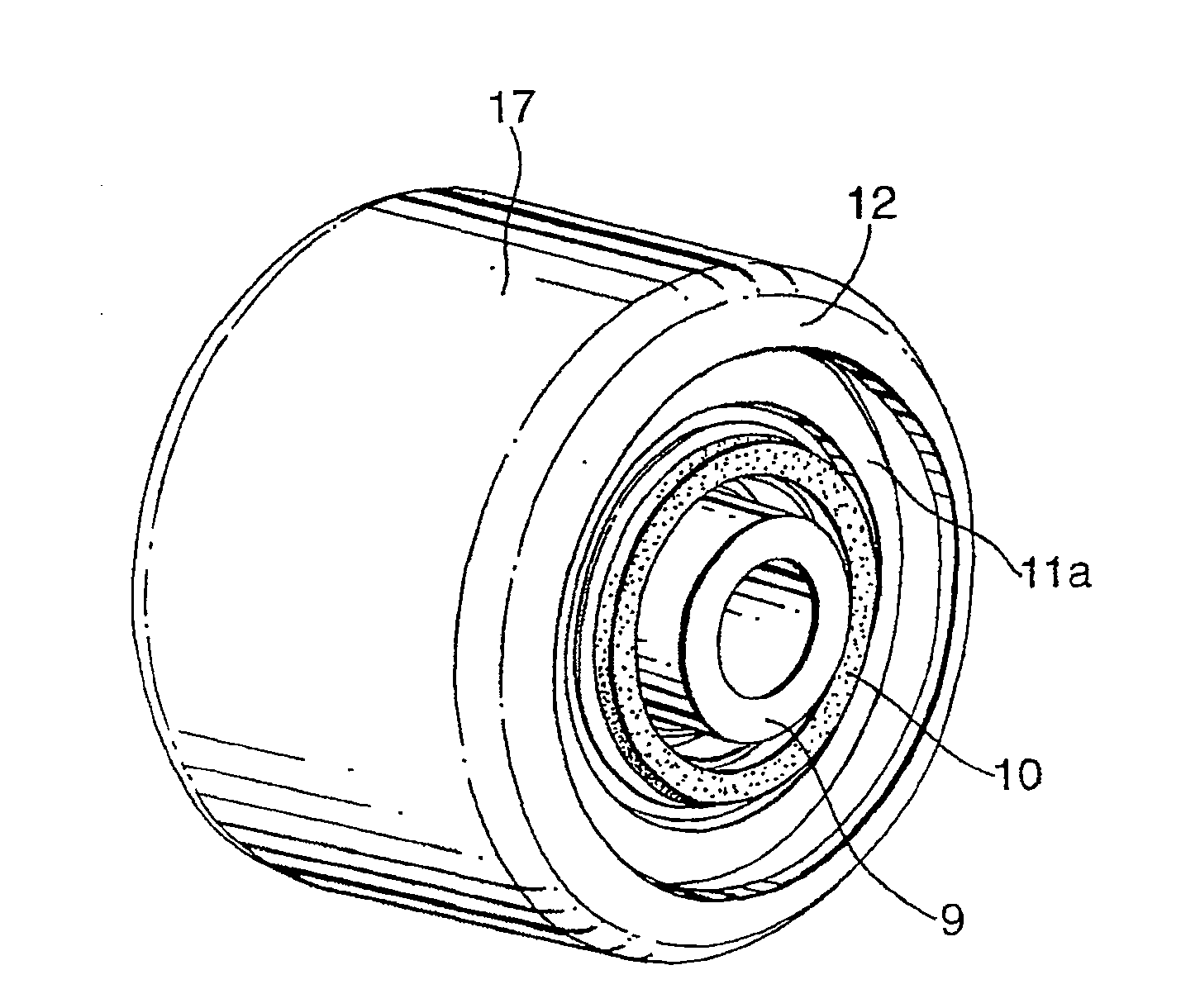

[0027]The first elastic member 10 is provided so as to be able to absorb displacement due to stress applied to the bushing arrangement in the vehicle transverse, longitudinal and vertical directions. Preferably, the first elastic member has appropriate rigidity in the vertical direction and softness in the transverse and longitudinal directions. The bushing arrangement 6a also comprises a second bushing element. The second bushing element comprises a second elastic element 13 and a second rigid sleeve 12 . The second rigid sleeve 12 is arranged radially spaced apart from the first rigid sleeve 11 and has a radially inner axial face 16 and a radially outer axial face 17 . The second elastic element 13 is arranged in the space between the first and the second rigid sleeve 11 , 12 . Alternatively, the second bushing element may be arranged somewhere between the first rigid sleeve 11 and the core 9, so as to be in a position radially closer to the central axis 9a of the core. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com