Double-firepot ring-shaped shaft kiln

A ring-shaped, shaft kiln technology, used in furnaces, vertical furnaces, lighting and heating equipment, etc., can solve problems such as output increase limitation, uneven airflow distribution, etc., to achieve the effects of good product quality, low failure rate, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

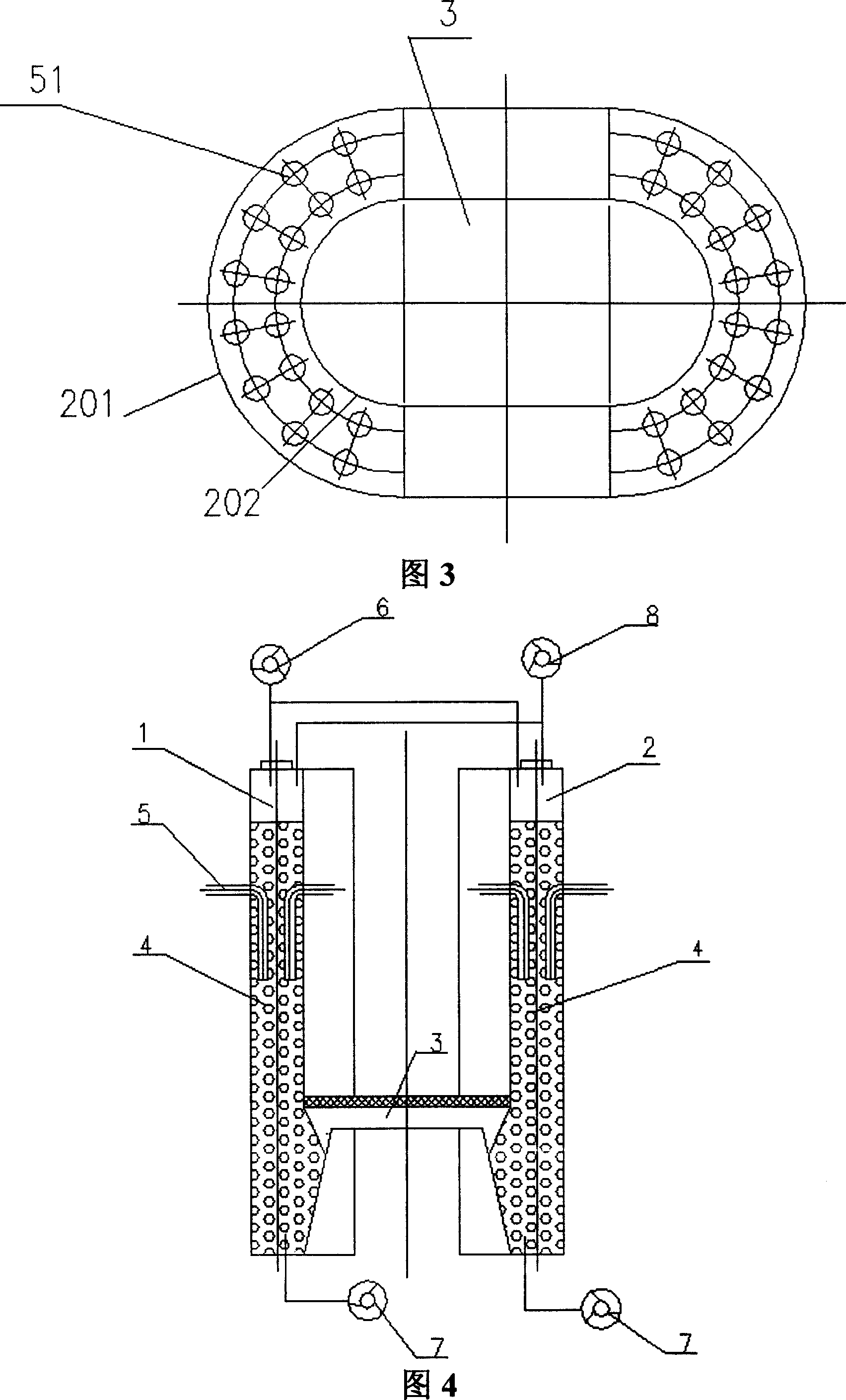

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

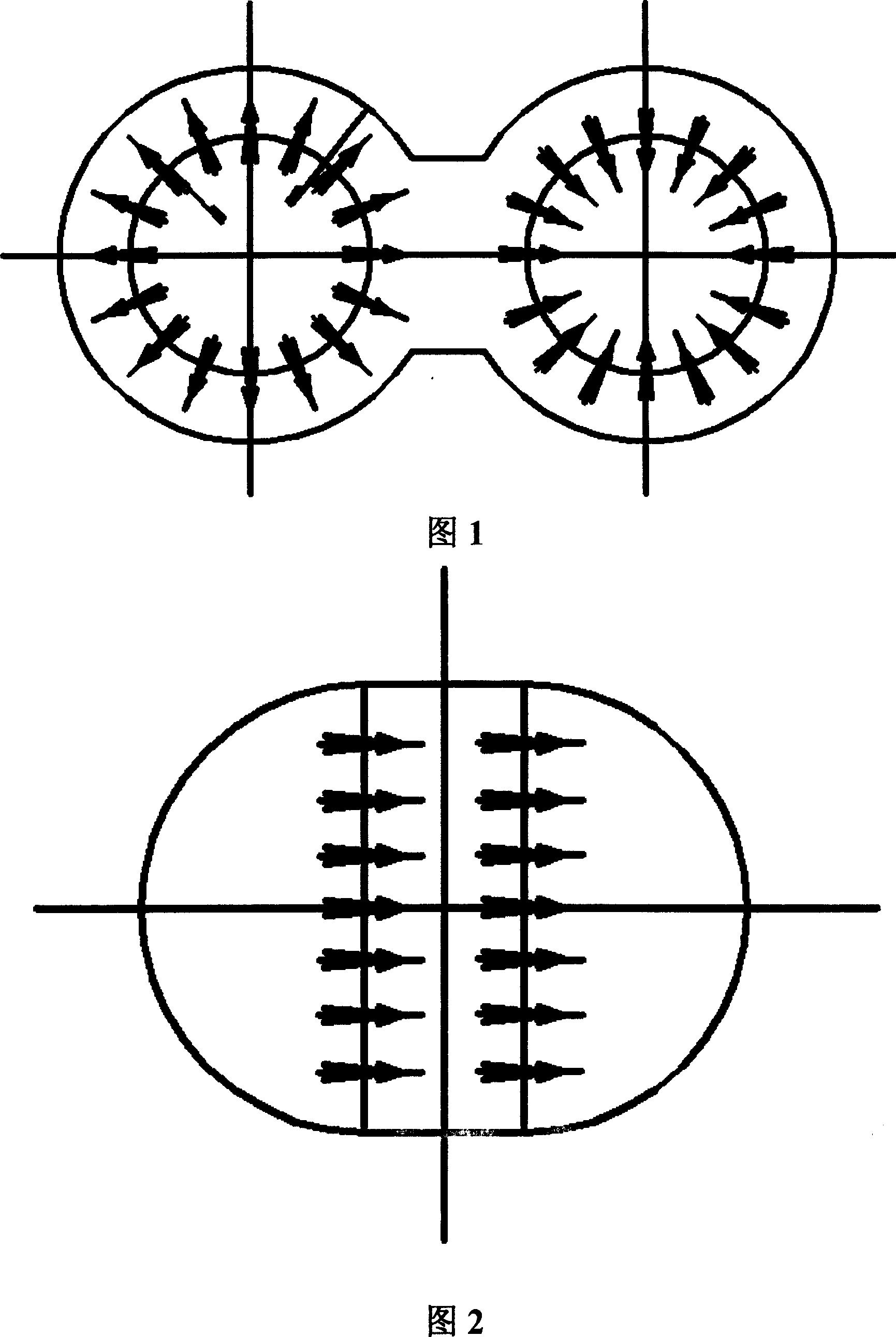

[0016] It can be seen from Figures 3 and 4 that the present invention includes: a first kiln tube 1 and a second kiln tube 2; the first kiln tube 1 and the second kiln tube 2 are connected together through a connecting channel 3; the first kiln tube 1 and the upper part of the second kiln tube 2 respectively include one or several feed openings and distributors (not shown in the figure), and one or several discharge ports are installed at the bottom of the first kiln tube 1 and the second kiln tube 2 (not shown in the figure); between the inner wall of the first kiln tube 1 and the second kiln tube 2, the burner nozzle 5 for the fuel required for the calcined material is included; between the first kiln tube 1 and the second kiln tube The top of 2 respectively includes a first blower 6 and an induced draft fan 8; when the first kiln barrel 1 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap