Load-carrying mechanism and CD-ROM using the same

A technology of a carrying mechanism and an optical drive, which is applied to the layout of structural components in the carrier equipment, the frame/frame structure, the structural components of the record carrier, etc. Problems such as screw action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

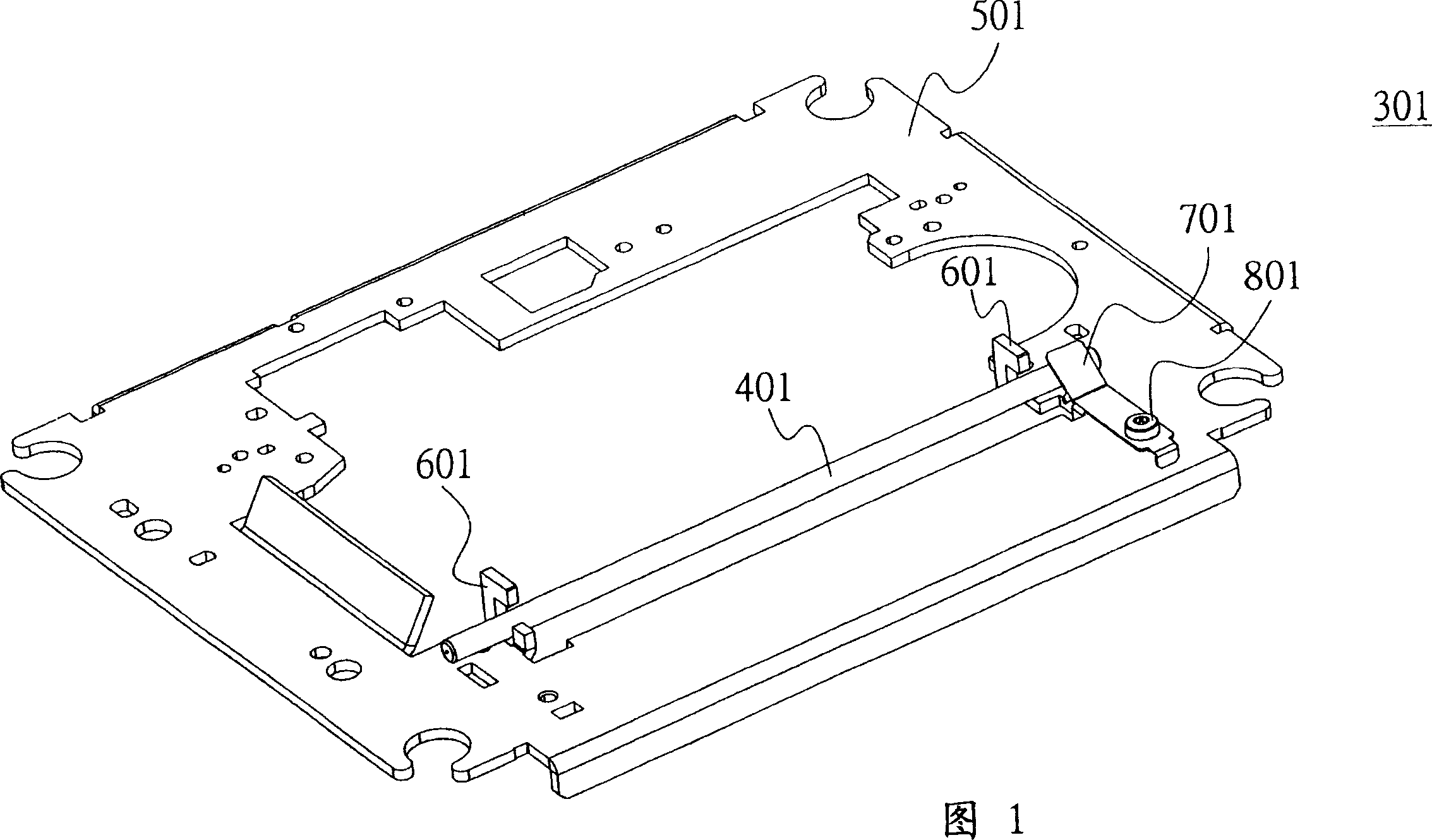

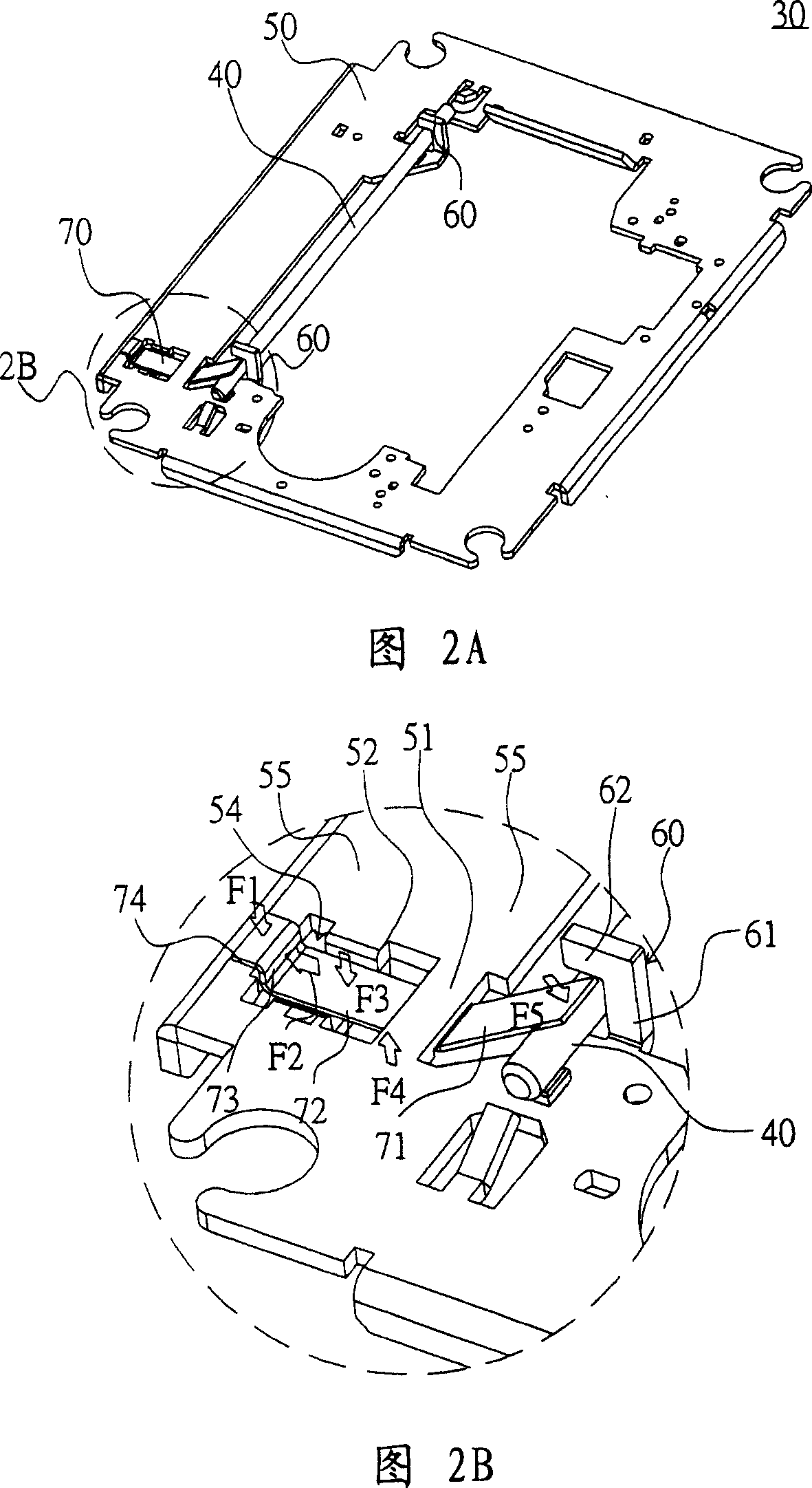

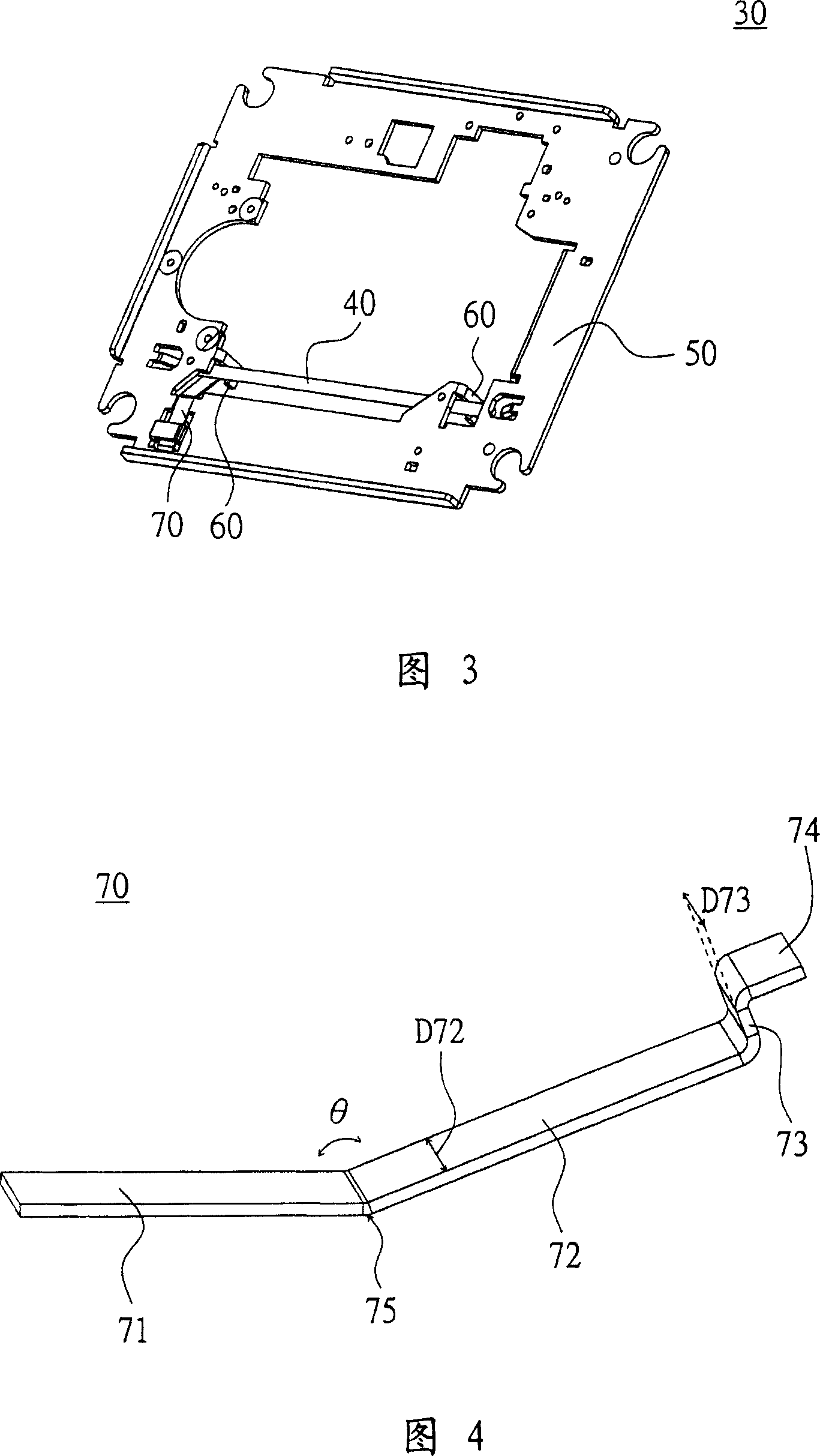

[0054] Please refer to FIG. 2A and FIG. 3 at the same time. FIG. 2A shows a schematic view of the bottom plate, guide shaft and shrapnel of the optical drive according to Embodiment 1 of the present invention. FIG. 3 is a back view of the bottom plate, guide shaft and elastic piece in FIG. 2A . The optical drive can be a read-only VCD drive, a rewritable VCD recorder, a read-only DVD drive, a rewritable DVD recorder, and a composite optical drive. The optical drive includes an optical pickup head, a bottom plate 50 , a guide shaft 40 and a shrapnel 70 . The bottom plate 50 , the guiding shaft 40 and the elastic piece 70 form a carrying mechanism 30 for carrying the optical pickup head. The carrying mechanism 30 is installed inside the optical drive. The guide shaft 40 is a cylindrical long shaft and is arranged on the bottom plate. The optical pickup head is coupled to the guide shaft 40 so that the optical pickup head can slide back and forth on the bottom plate 50 through...

Embodiment 2

[0062] Please refer to FIGS. 6A-6B and FIG. 7 at the same time. FIG. 6A is a schematic diagram of the bottom plate, guide shaft and shrapnel of the optical drive according to the second embodiment of the present invention. FIG. 6B shows a partially enlarged view of the dotted line area 6B in FIG. 6A . FIG. 7 is an enlarged view of the shrapnel shown in FIG. 6 . The difference between the bearing mechanism of this embodiment and the bearing mechanism of Embodiment 1 lies in the structural design of the elastic piece 90 , and the same reference numerals are used for the rest of the similarities, which will not be repeated here. In this embodiment, the elastic piece 90 extends from the second long piece 92 and directly abuts against the bottom of the bottom plate 50 .

[0063] When the guide shaft 40 , the bottom plate 50 and the elastic piece 90 are combined, the elastic piece 50 is tightly pressed against the guide shaft 40 on the bottom plate 50 . Two ends of the second long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com