Separate adjustable U-shaped arm for gyro stabilization high definition camera system and assembly method thereof

A technology of gyro stabilization and assembly method, which is applied to the parts of TV systems, the body of cameras, and the parts of color TVs, etc., can solve the problem of high requirements for processing equipment, prolonged processing cycles, and poor product interchangeability. and other problems, to achieve the effect of improving interchangeability and versatility, reducing the risk of deformation, and reducing the difficulty of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

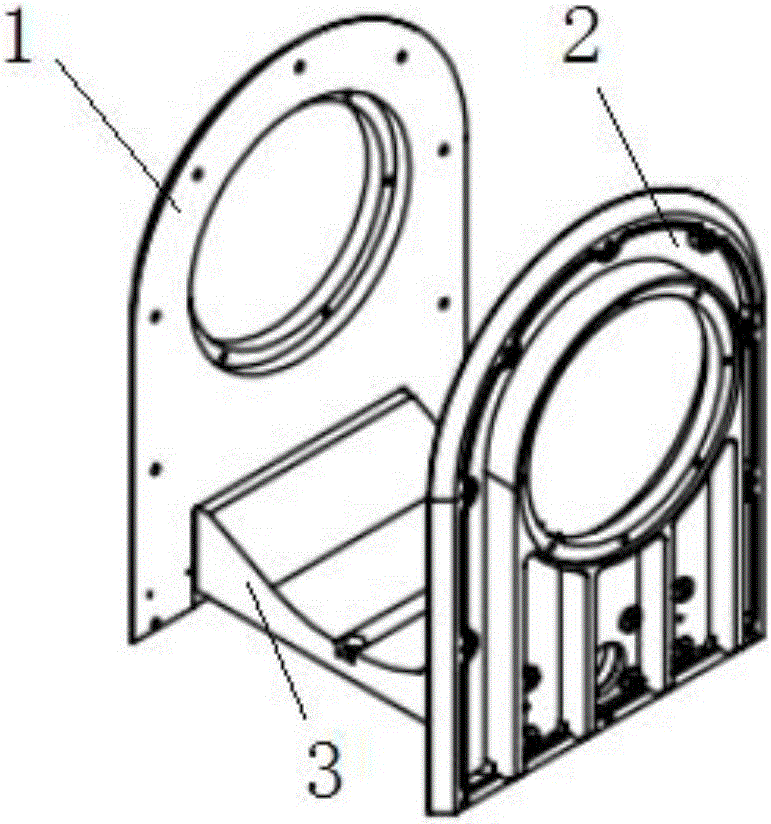

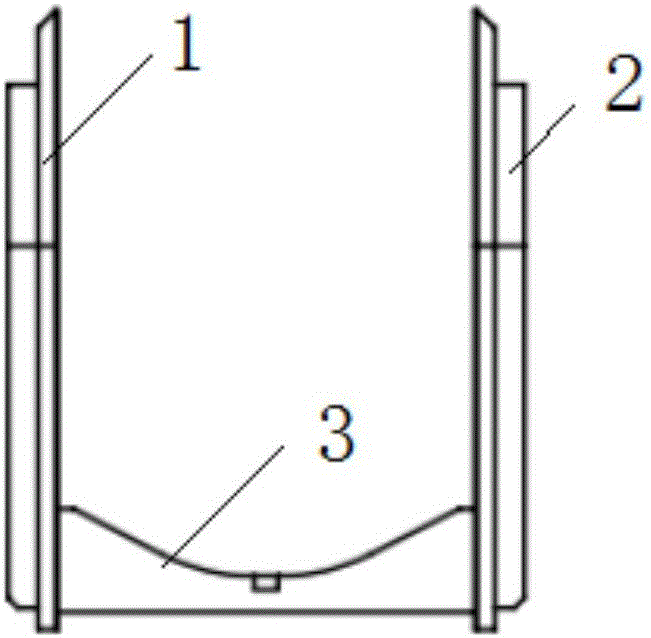

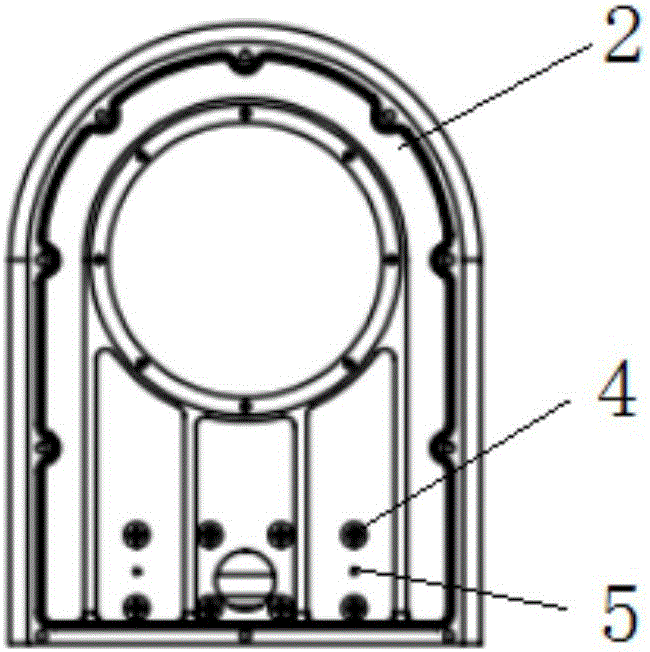

[0014] In the present invention, the U-shaped arm is divided into three parts and processed separately. The structure of the U-shaped arm of the present invention is as follows: Figure 1-4 As shown, 1 is the left yoke, 2 is the right yoke, 3 is the middle housing, 4 is a screw, and 5 is a pin. The left and right wishbone structures can be completely the same or different. The left and right yokes have screw holes connected to the middle housing. Preferably, the screw holes are located at the lower ends of the left and right yokes 1 and 2 and are arranged in two rows. The left and right yokes 1 and 2 are respectively connected to the middle shell 3 through screws 4. After the pitch shafting structure is installed, the tightness of the screws 4 can be manually adjusted so that when the pitching shaft rotates with the bearing, the bearing rotates smoothly. There is no stuck ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com