Brown-coal green extractive solvent

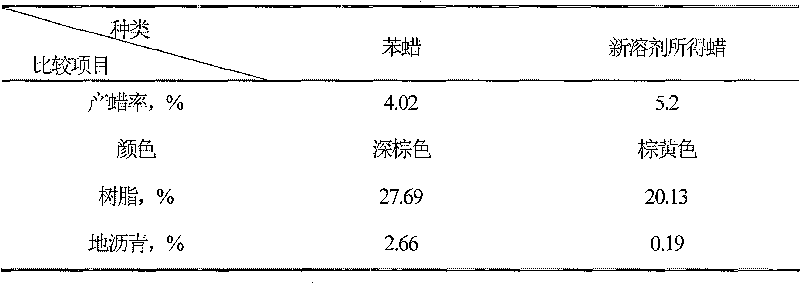

A technology for extracting solvents and montan wax, which is applied in the field of montan wax extraction solvents, can solve the problems of operators' physical and surrounding environment hazards, unsatisfactory selectivity of benzene to wax, and limited use fields, etc., so as to benefit the operating environment and the surrounding environment , high wax extraction rate, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

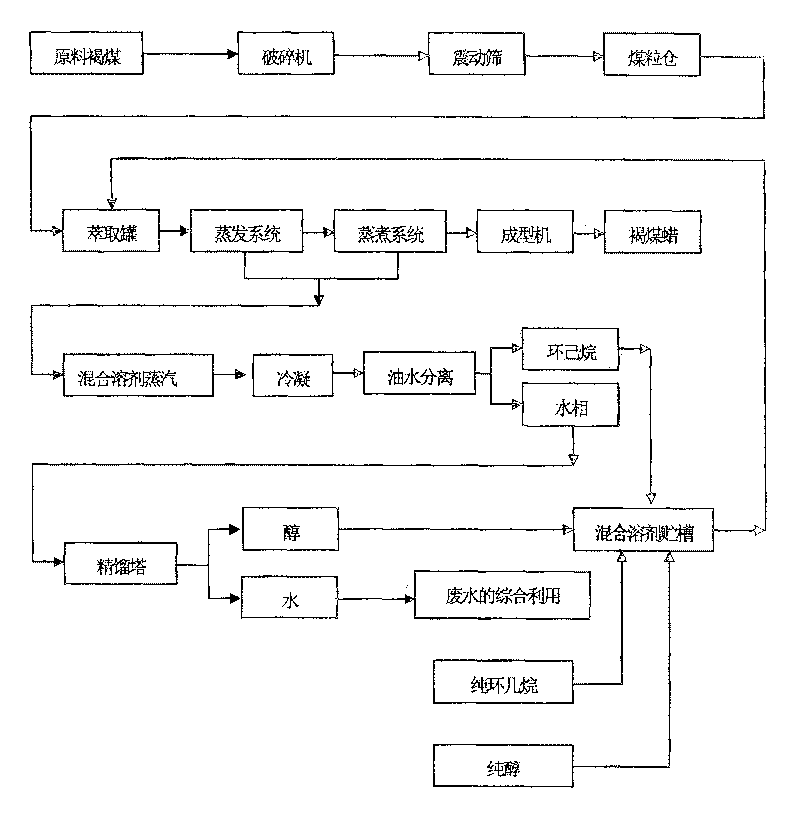

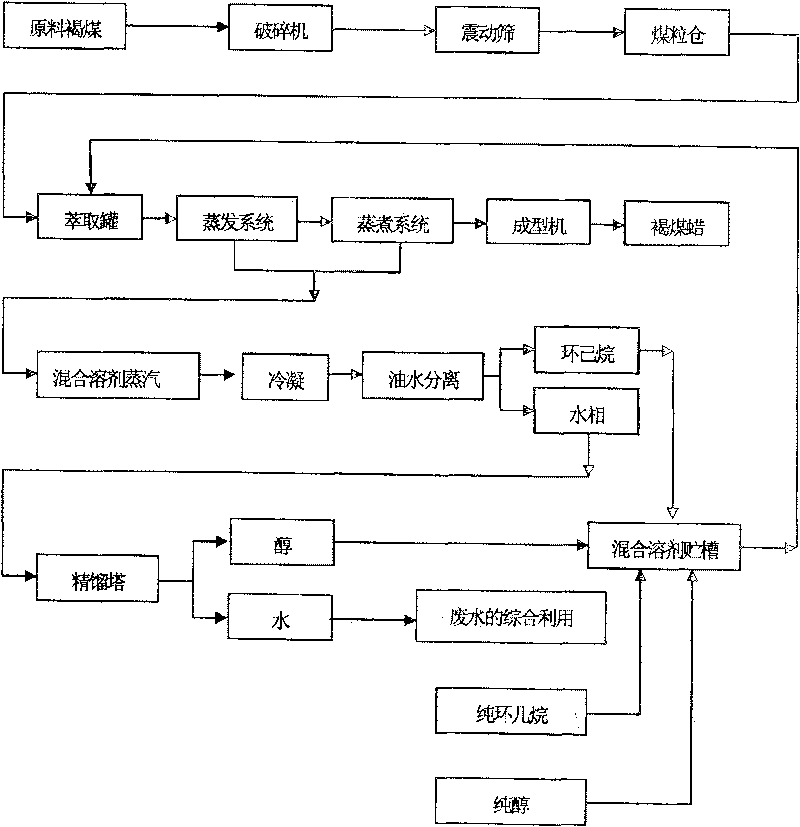

Method used

Image

Examples

Embodiment 2

[0023] Example 2: Mixed solvent formula: the mass percentage of cyclohexane and tert-butanol (methanol or ethanol) is 80%:20%. The production process is basically the same as that of the first embodiment, but the difference is that: a group of three tanks are used for extraction, and the solvent is operated countercurrently. The specific process is: sending the fresh mixed solvent of cyclohexane and tert-butanol (methanol or ethanol) into the extraction tank where the lignite has been extracted twice, and under the same conditions as in Example 1, after 1 hour of extraction Then the lignite is sent to the extraction tank where the lignite has been extracted once, and then the unextracted lignite is extracted. After the lignite is extracted three times, it is discharged and replaced with new coal, which is carried out in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com