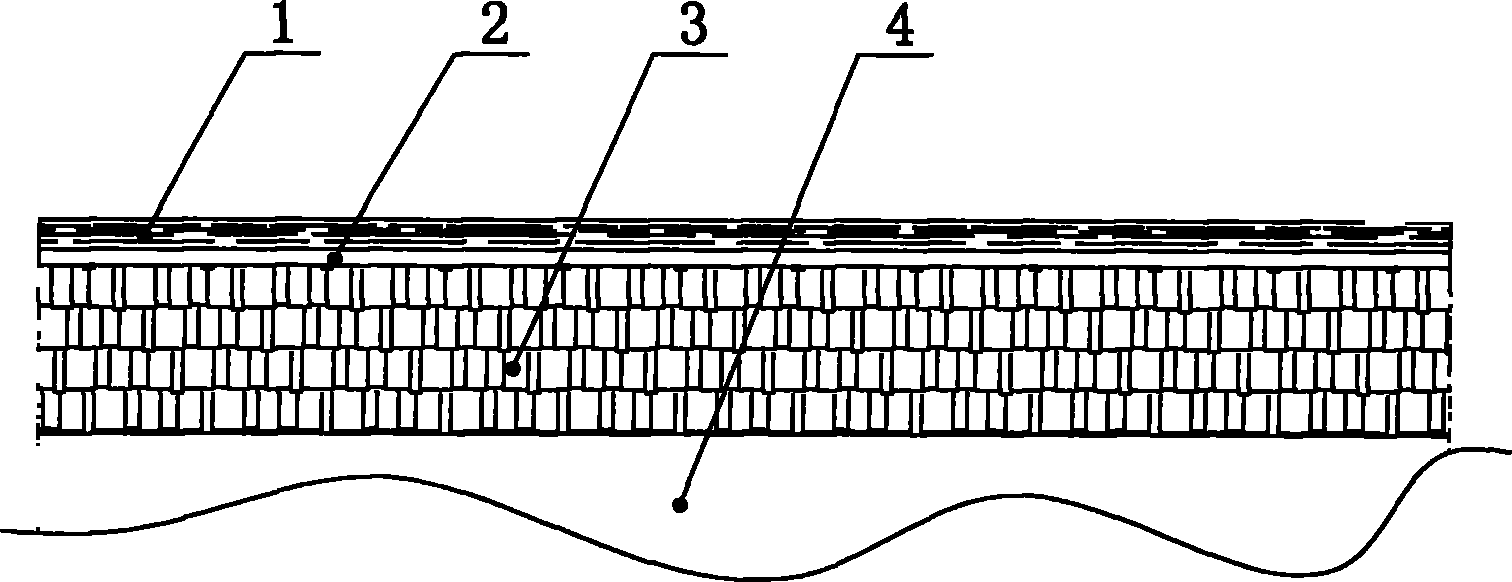

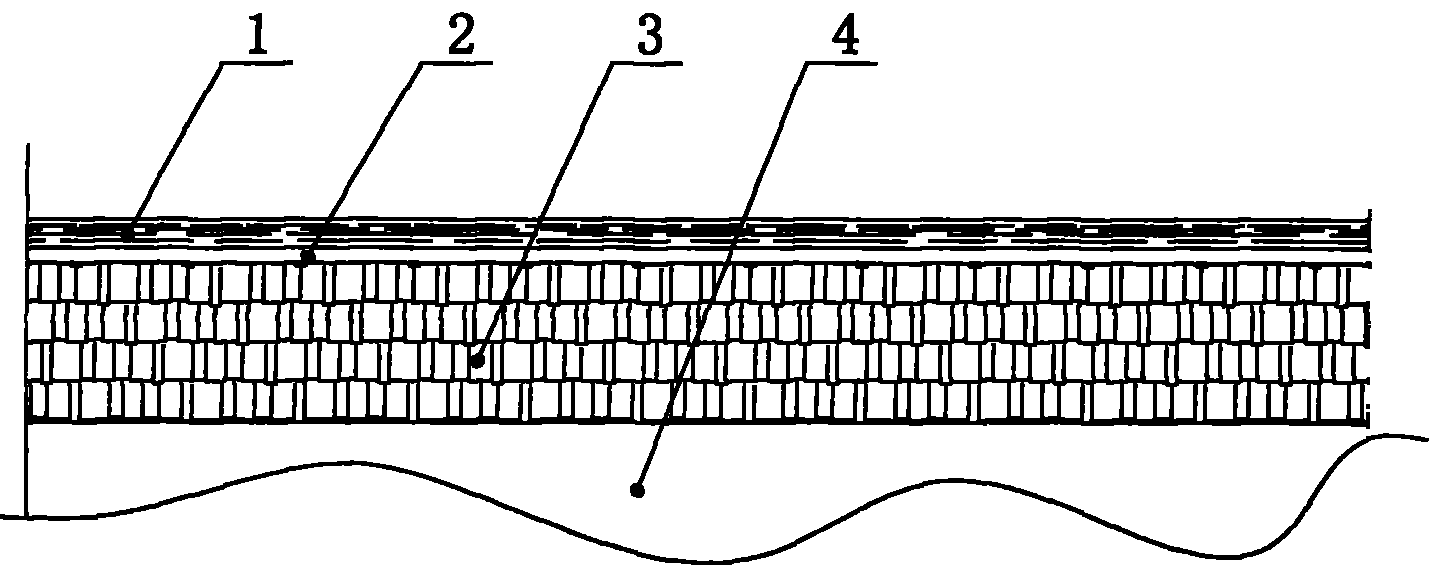

Pavement maintained by adopting cold regeneration technology and construction method thereof

A construction method and cold recycling technology, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of inability to process waste, pollute the environment, long construction period, etc. quantity, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055]Taking a pavement with a length of 1km and a width of 3.75m and a treatment thickness of 18cm as an example, the steps of the road surface maintenance method using cold recycling technology are as follows:

[0056] (1) On-site milling of the original damaged asphalt pavement to obtain RAP (recycled asphalt pavement).

[0057] (2) Optimize and adjust the gradation of RAP, and prepare foamed asphalt cold recycled mixture by using factory-mixed cold recycling method, specifically: transport RAP back to the cold recycling mixing plant, and use factory-mixed RAP, asphalt, cement, and water Cold recycling equipment for mixing, the weight of each material is:

[0058] RAP 1485t;

[0059] Asphalt 34.2t;

[0060] Cement 22.3t;

[0061] Water 83.2t,

[0062] After stirring evenly, the foamed asphalt cold recycled mixture is obtained.

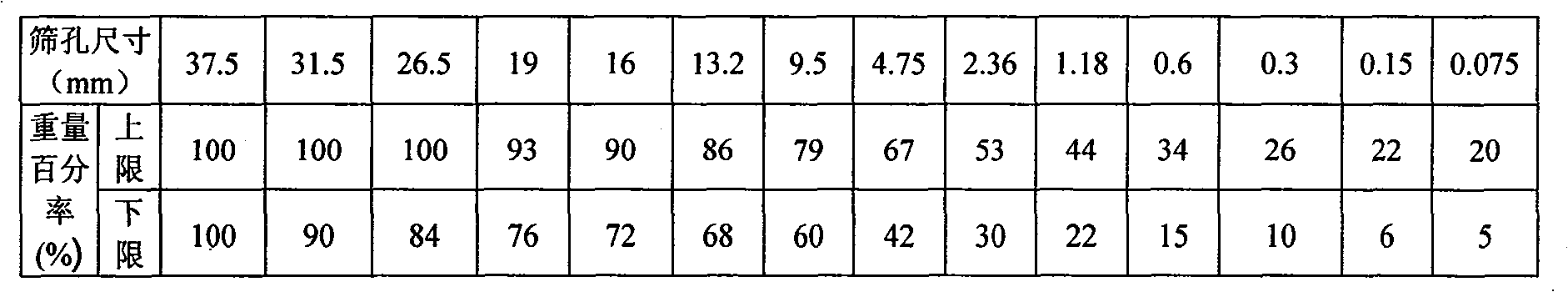

[0063] The gradation range of foamed asphalt cold recycled mixture prepared according to RAP is:

[0064] mesh size

(mm)

...

Embodiment 2

[0072] Taking the pavement with a length of 1km, a width of 3.75m, and a treatment thickness of 20cm as an example, the steps of the construction method of repairing the pavement with cold recycling technology are as follows:

[0073] (1) On-site milling and planing of the original damaged cement-stabilized base to obtain CTB (recycled cement-stabilized base).

[0074] (2) Optimize and adjust the CTB gradation, and prepare the foamed asphalt cold recycled mixture by using the in-situ cold recycling method. Specifically, the CTB, asphalt, cement, and water are used to regenerate the foamed asphalt on the spot and complete the spreading at the same time. For paving, the cement is sprinkled by cement slurry truck, and the weight of each material is as follows:

[0075] CTB 1575t;

[0076] Asphalt 42.5t;

[0077] Cement 31.5t;

[0078] 151.2t of water,

[0079] The gradation range of foamed asphalt cold recycled mixture prepared according to CTB is:

[0080] mesh siz...

Embodiment 3

[0088] Taking a pavement with a length of 1km, a width of 3.75m, and a treatment thickness of 20cm as an example, the steps of the construction method for repairing the pavement with cold recycling technology are as follows:

[0089] (1) On-site milling of cement-stabilized base to obtain CTB (recycled material of cement-stabilized base).

[0090] (2) Optimizing and adjusting the CTB gradation, adopting the in-situ cold regeneration method to prepare foamed asphalt cold recycled mixture, specifically the same as in Example 2, and the weights of each material are respectively:

[0091] CTB 1307t;

[0092] Asphalt 44.1t;

[0093] Cement 31.5t;

[0094] Fine aggregate 267.8t;

[0095] Water 155.9t;

[0096] The gradation range of foamed asphalt cold recycled mixture prepared according to CTB is:

[0097]

[0098] In this embodiment, fine aggregates with a particle size ranging from 0 to 5 mm are added to meet the gradation requirements of the foamed asphalt cold recycled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com