Adjustable axial-flow type drum thresher

A drum threshing device and adjustable technology, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve problems such as unclean threshing of crops, increased loss rate and damage rate, etc., to reduce the damage rate and reduce the loss rate. , threshing clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

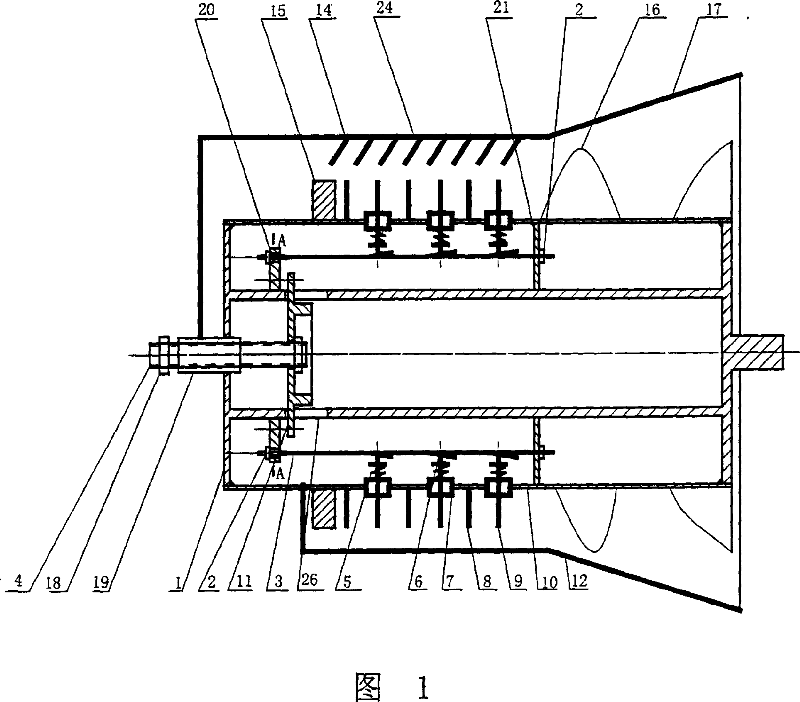

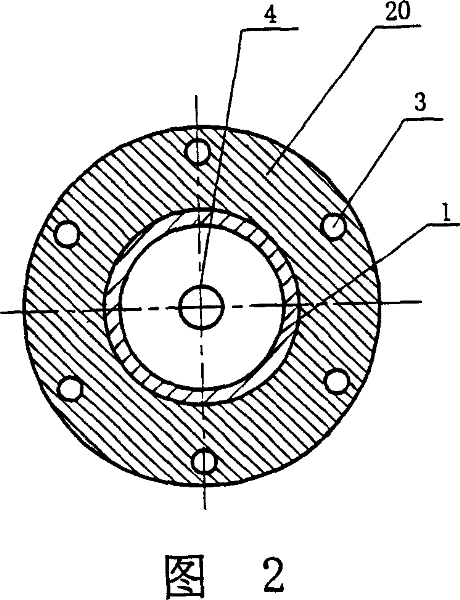

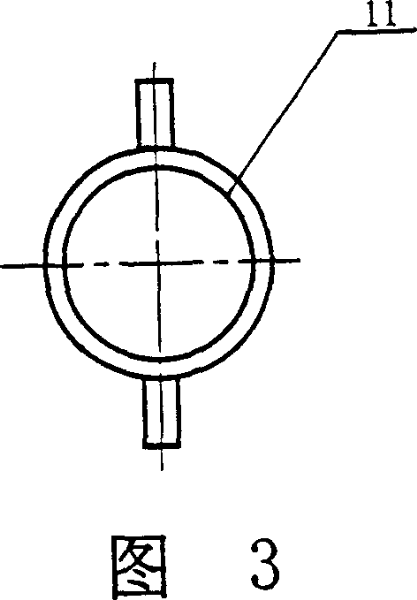

[0020] As shown in Figure 1, the adjustable axial flow drum threshing device of the present invention includes: a rotating shaft 1, spikes, spiral pieces 16, feeding trough 12, baffle plate 17, and upper cover 14. The spiral pieces 16 are mounted on the rotating shaft 1. At the front end, the nail teeth are fixed in the axial center of the rotating shaft 1, and the nail teeth are evenly distributed along the axial and radial directions of the rotating shaft 1. The nail teeth include a fixed nail tooth 8 and a movable nail tooth 9. The frame 10 is fixed on the rotating shaft 1. One end of the movable spike 9 extends from the fixed sleeve 7 fixed on the fixed frame 10, and the other end is connected to the wedge 6 on the tie rod 3 that slides along the axis of the rotating shaft 1. For inclined surface contact, the movable spike 9 is equipped with a spring 5, one end of the spring 5 is in contact with the fixed sleeve 7, and the other end is in contact with the inclined surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com