Threshing machine

A technology of thresher and spiral plate, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as non-conformity, affecting the germination rate of seeds, affecting the life of the thresher machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

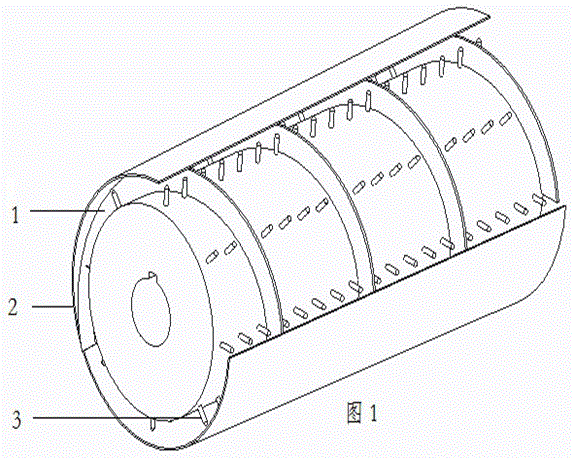

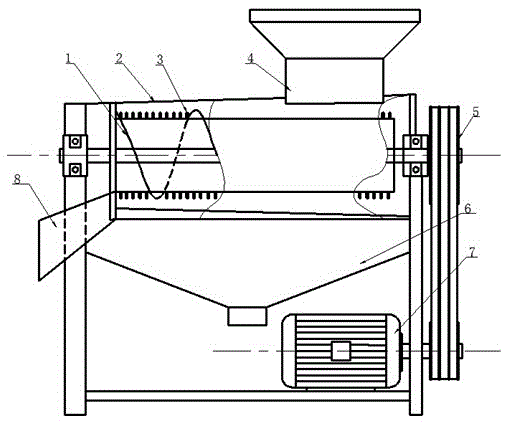

[0009] refer to figure 1 , figure 2 As shown, the main structure of the thresher includes: the ear of corn is fed from the feeding port (4), the ear of corn rotates with the helical teeth (1) on the drum, and is subjected to polyurethane during the forward movement along the axial direction. The brushing of the flexible rod teeth (3) and the extrusion of the tapered drum shell (2) achieve threshing under the action of friction. The threshed corn fruit is collected by the collecting hopper (6), and the corn cob is finally discharged from the core discharge port (8) at the rear end of the thresher.

[0010] This new design is based on threshing dynamics, and simplifies the threshing process to the impact of grains with mass M at the initial velocity V0, which can be simplified as the tooth end of the threshing tooth of the elastic cantilever beam, so the threshing tooth fixed on the drum can be flexibly Rod teeth (3) are equivalently regarded as cantilever beams deformed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com