Lifting electro-magnet for lifting circular-section long material

A technology of lifting electromagnet and circular section, which is applied in the field of lifting electromagnet, can solve the problems that lifting electromagnet is not suitable for lifting, and achieve the effect of simple structure, increased magnetic force, and increased lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

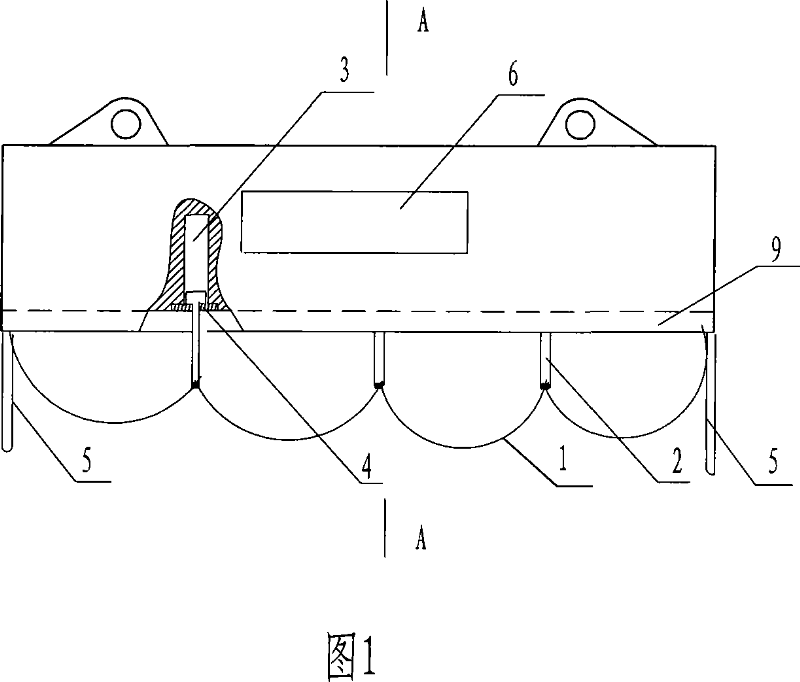

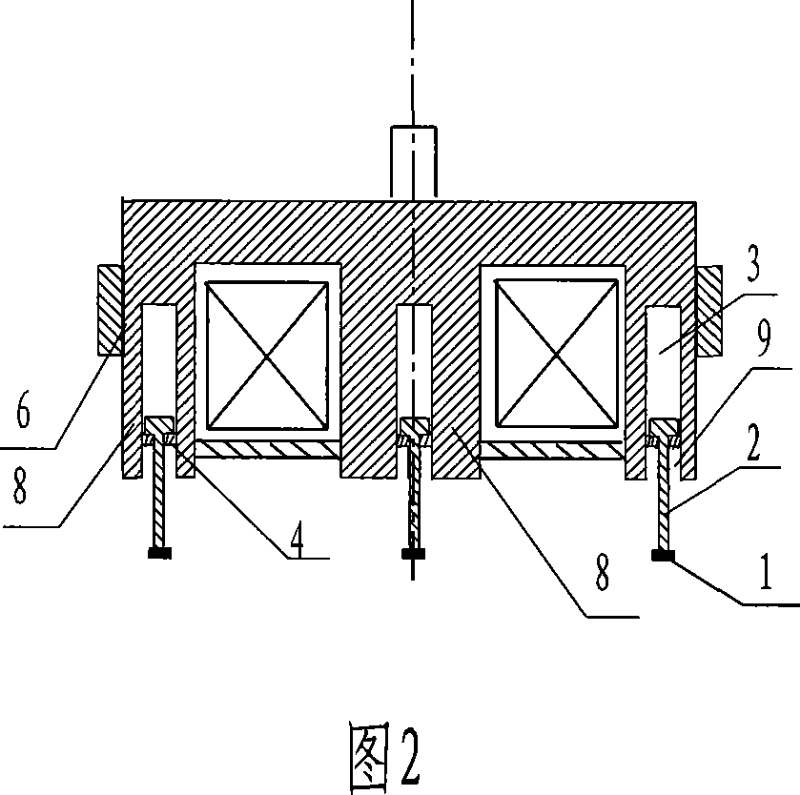

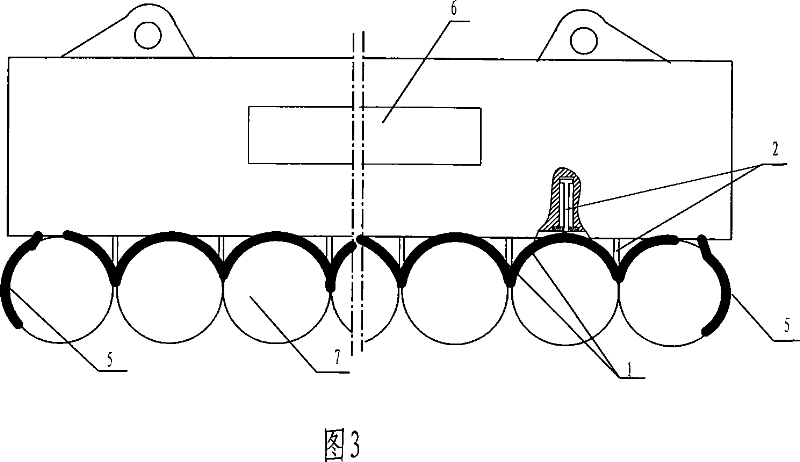

[0013] As shown in Fig. 1 and Fig. 2, it can be seen that the hoisting electromagnet of the present invention is a "U" shape or an "E" electromagnet for hoisting circular cross-section long materials, and the preferred "E" electromagnet of the present invention has a length of 1800mm of each magnetic pole 8 , the bottom surface can be a plane, or there can be a through groove 9 in the length direction of the bottom surface. The preferred magnetic pole 8 of the present invention has a through groove 9 in the length direction of the bottom surface. The width is 40mm, and 20 vertical cavities 3 are evenly distributed on the center line of the through groove 9. The cavities 3 run through the bottom of the magnetic pole 8. A guide post 2 with a longitudinal section of "T" shape is housed in the cavity 3. Each After each cavity 3 is loaded into a guide column 2, a baffle plate 4 with a hole is installed at its bottom, so that the lower end of the guide column 2 protrudes from the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com