Laser cladding device with adjustable wire outlet direction

A laser cladding and wire technology, applied in metal material coating process, coating and other directions, can solve the problems of high skill requirements, damage, risk of increasing maintenance costs, etc., to ensure accuracy, reduce nozzle wear, improve Sliding smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

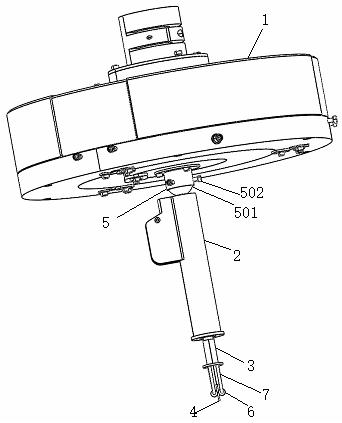

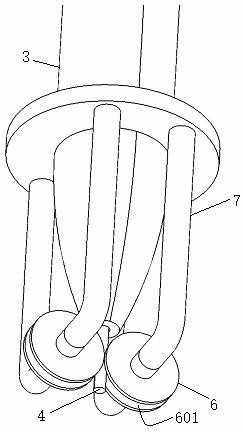

[0027] see figure 1 , figure 2 and Figure 7 As shown, a laser cladding device with adjustable wire outlet direction includes a three-beam laser cladding nozzle 1, the three-beam laser cladding nozzle 1 is connected to a wire nozzle 3 through a wire guide post 2, and the wire One side of the material guide post 2 is provided with a wire entry hole 201 and a wire passage 202 is opened in the middle, and the wire 4 used for cladding enters the wire passage 202 from the wire entry hole 201 and passes through the wire passage 202. The incident laser beam passes through the three-beam laser cladding nozzle 1 to generate three beams projected below the wire nozzle 3 and envelops the wire 4 emitted from the wire nozzle 3. The wire guide post 2 is movably connected with the three-beam laser cladding nozzle 1 .

[0028] Further, the wire guide post 2 is movably connected with the three-beam laser cladding nozzle 1 through a universal ball hinge mechanism 5 .

[0029] Further, the ...

Embodiment 2

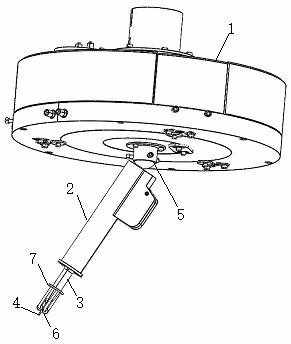

[0034] see Figure 4 , Figure 5 and Figure 7As shown, a laser cladding device with adjustable wire outlet direction includes a three-beam laser cladding nozzle 1, the three-beam laser cladding nozzle 1 is connected to a wire nozzle 3 through a wire guide post 2, and the wire One side of the material guide post 2 is provided with a wire entry hole 201 and a wire passage 202 is opened in the middle, and the wire 4 used for cladding enters the wire passage 202 from the wire entry hole 201 and passes through the wire passage 202. The incident laser beam passes through the three-beam laser cladding nozzle 1 to generate three beams projected below the wire nozzle 3 and envelops the wire 4 emitted from the wire nozzle 3. The wire guide post 2 is movably connected with the three-beam laser cladding nozzle 1 .

[0035] Further, the wire guide post 2 is movably connected with the three-beam laser cladding nozzle 1 through a universal ball hinge mechanism 5 .

[0036] Further, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com