Spray arm bearing and dishwasher with a spray arm arrangement

A spray arm, dishwasher technology, applied to spray devices, dishwashers/washers for tableware, spray devices with movable outlets, etc., can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

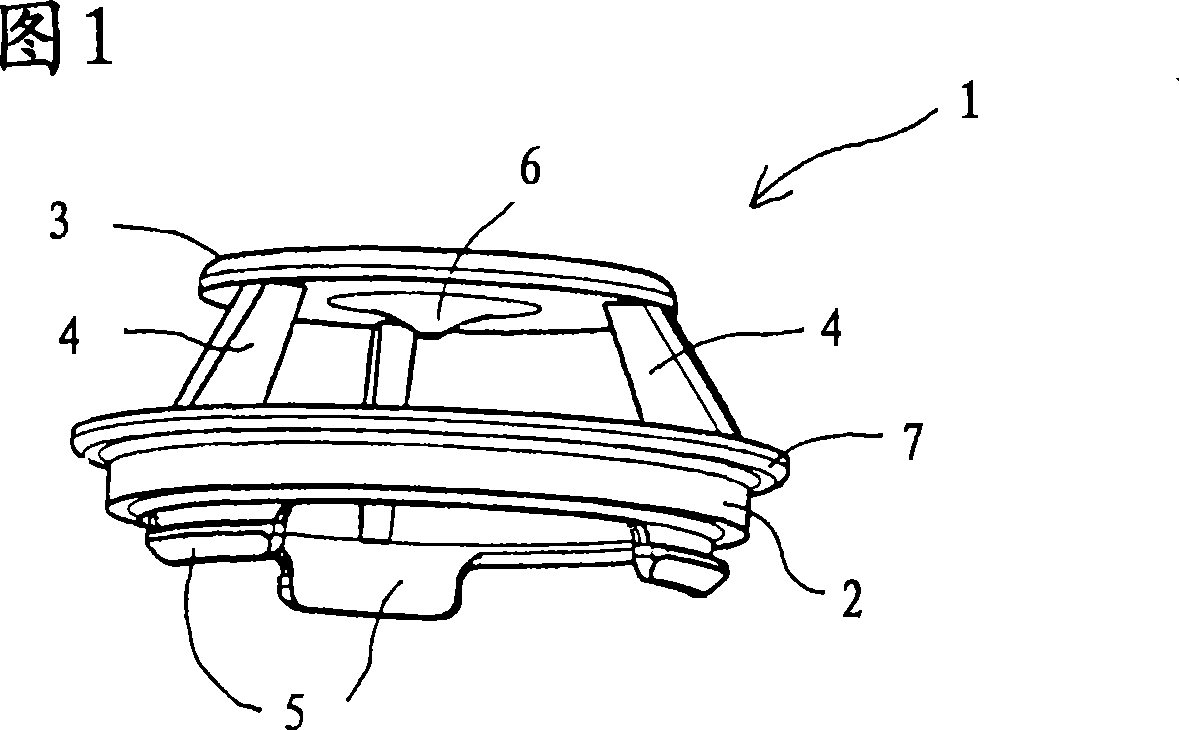

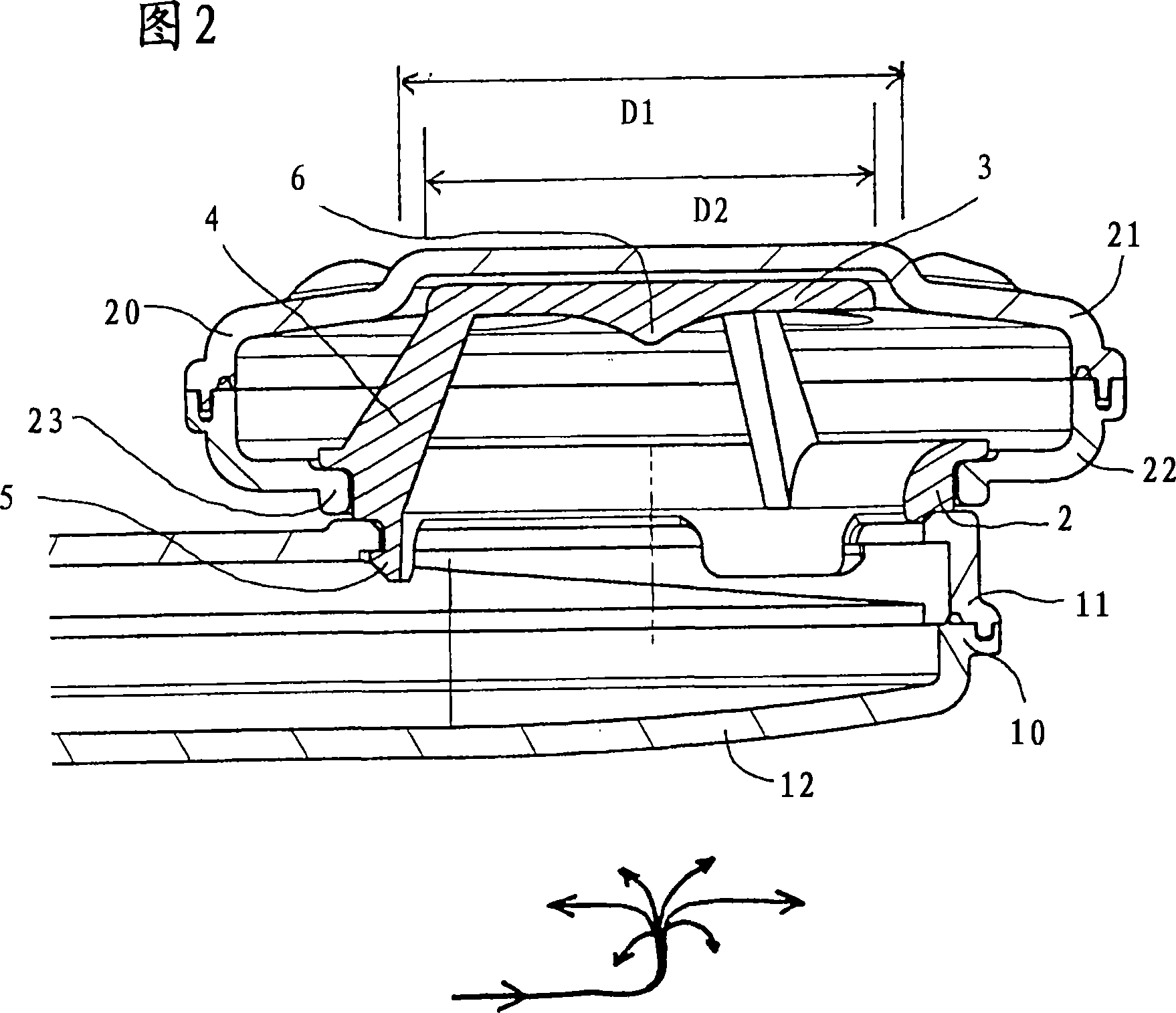

[0010] FIG. 1 shows a perspective view of a spray arm bearing 1 . As shown in cross section in FIG. 2 , the spray arm bearing 1 is used to connect an inlet piece 10 for feeding rinsing liquid to a spray arm 20 , which is rotatably mounted on the spray arm bearing 1 . The spray arm bearing 1 comprises a bearing ring 2 with an outer bearing surface which is delimited in the axial direction (upward as depicted in FIG. 1 ) by an annular projection 7 . A top 3 serving as a flow guide is connected to the bearing ring 2 via ribs 4 . In the axial cross-section, the ribs 4 extend substantially in the radial direction and have the smallest width in the circumferential direction, so that the ribs 4 offer less flow resistance to a liquid flow deflected in the radial direction. On the side opposite the top 3, an axially protruding stop 5 is arranged on the bearing ring 2, with which stop the spray arm bearing 1 snaps into the outlet on the inlet part 10 (FIG. 2) .

[0011] A hyperbolic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com