Multidirection press die

A stamping die and die base technology, which is applied in the field of forging production of workpieces with complex shapes, can solve the problems of energy consumption, multi-directional bosses, holes, etc., which cannot be completely formed at one time, and time-consuming, etc., to achieve significant benefits and slider transmission Simple, flexible and well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

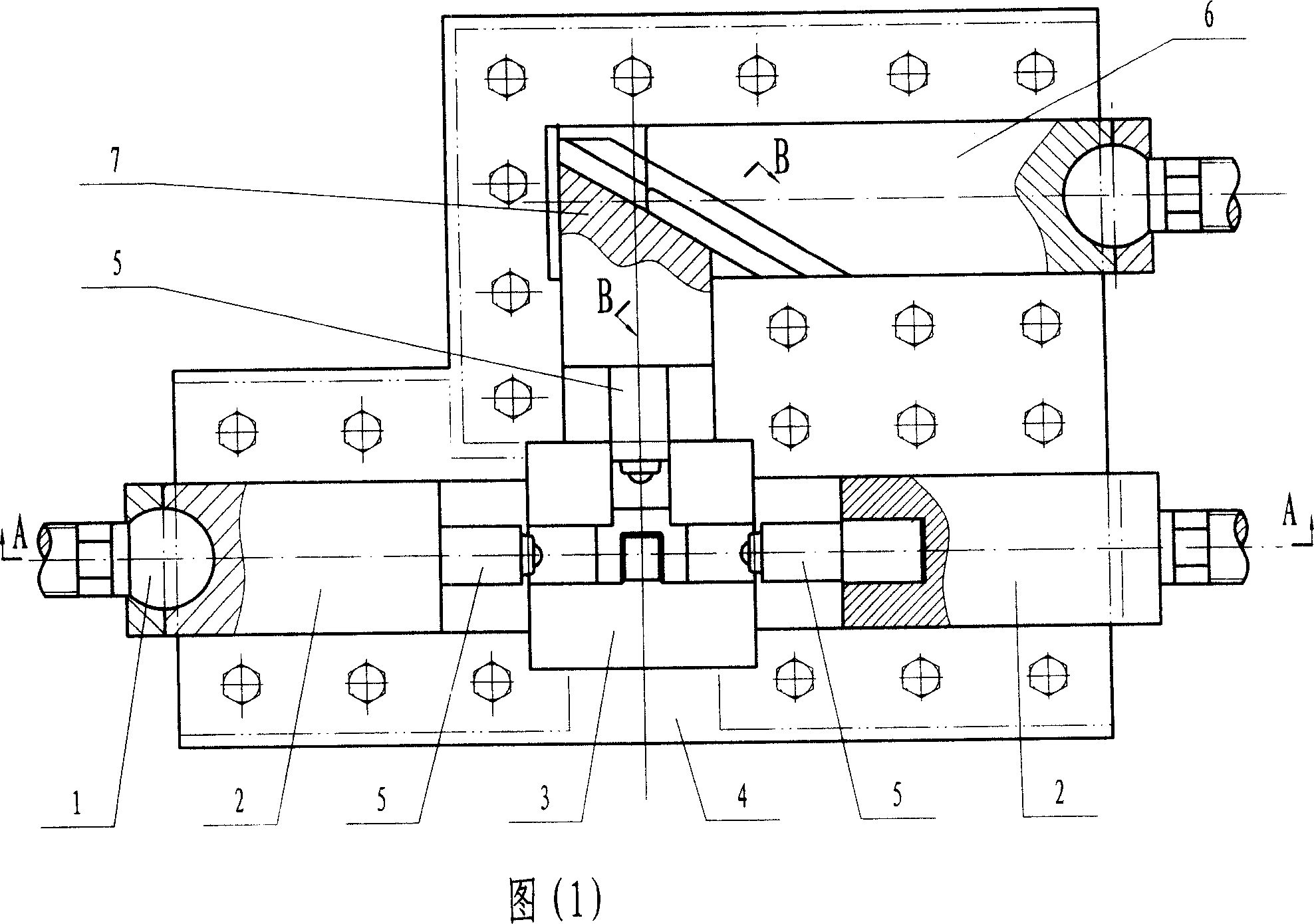

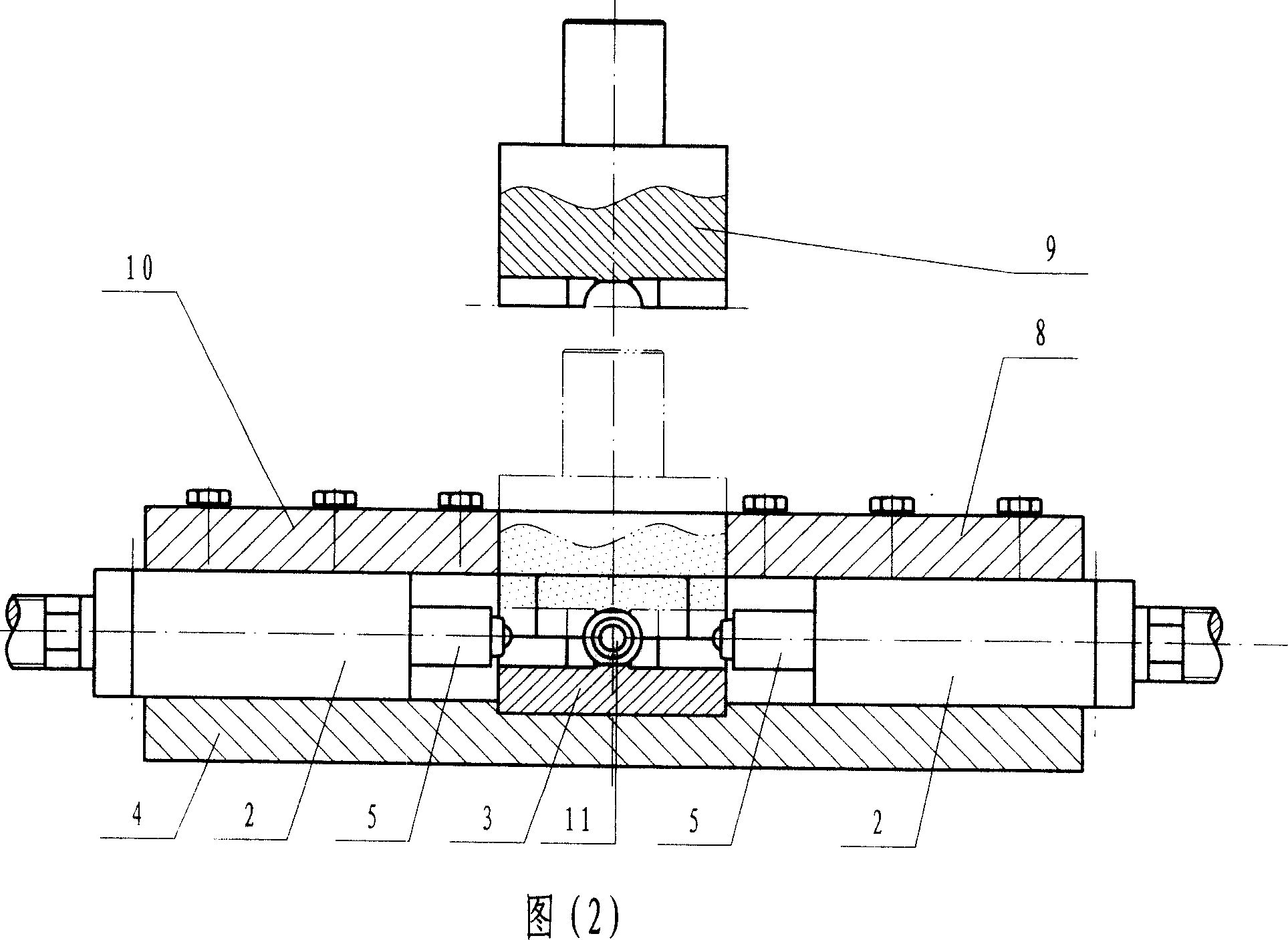

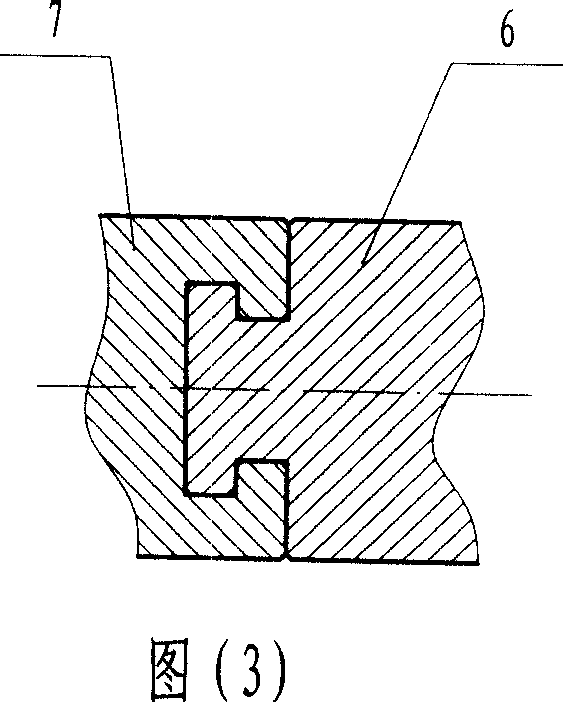

[0011] As shown in the accompanying drawings: this is an example of the application of the present invention to a three-way forging die. The lower die 3 located in the middle of the mold base 4 shows a three-way workpiece, which must be stamped from three directions at the same time to make the workpiece in three directions. The upper boss and hole. On the symmetrical position on both sides of the lower die 3, two linear motion slide blocks 2 are set, on which punches 5 are housed. The power of the slider 2 is supplied by the power ball head 1 on the connecting rod of the multidirectional punching machine; the punch 5 in the vertical direction is installed on the wedge-type passive slider 7 . The T-shaped head on the wedge surface of the active wedge slider 6 (Figure 3) cooperates with the T-shaped groove on the wedge surface of the passive slider 7 to change the transmission direction to realize stamping in the vertical direction, and the power on the active slider 6 also com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com