Rotary cutter for mowing machine

一种旋转刀具、割草机的技术,应用在收割机、农业机械和机具、切割器等方向,能够解决重量增加、抽出绳索危险、结构复杂等问题,达到稳定抽出长度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

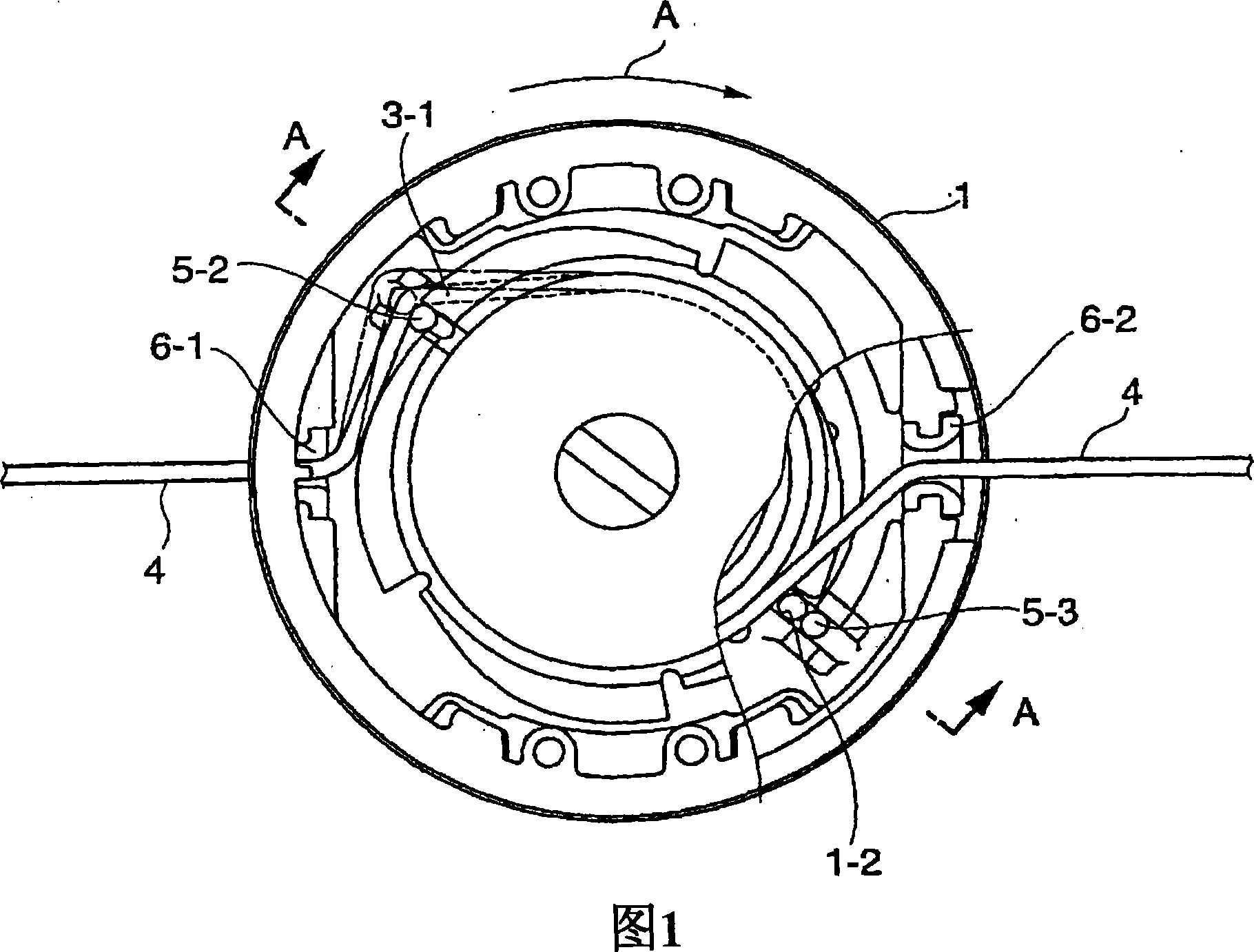

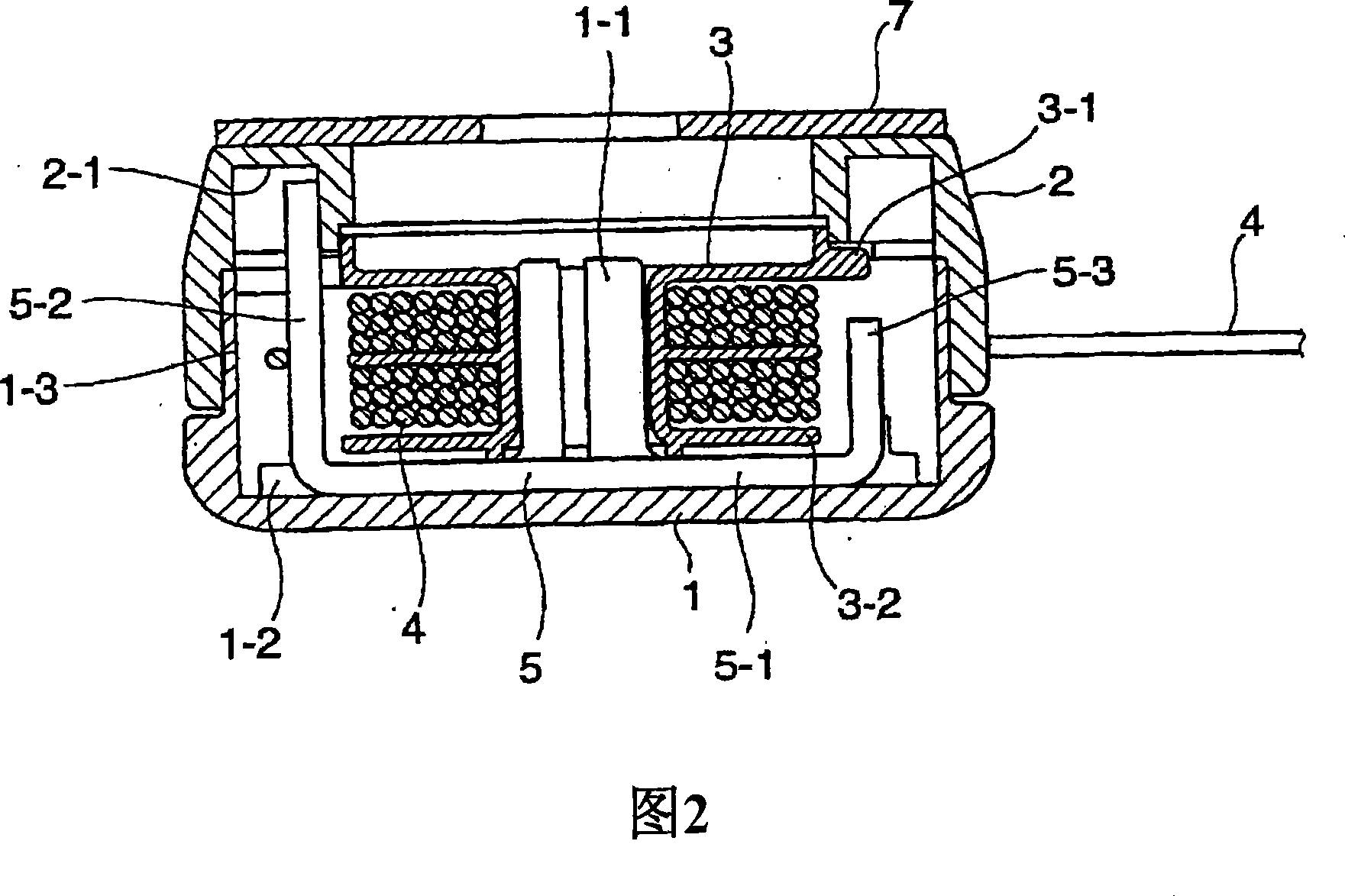

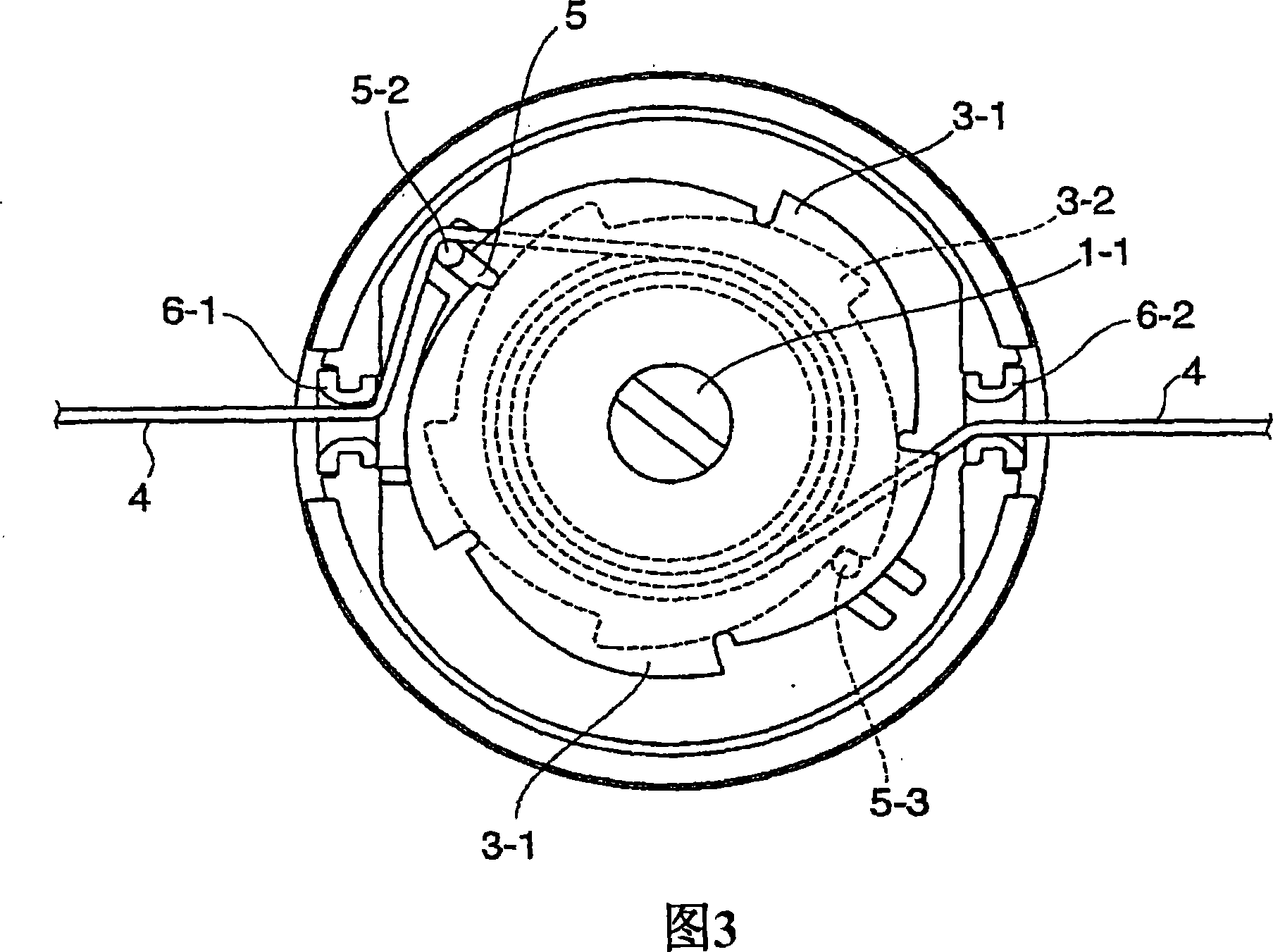

[0026] Fig. 1 is a partial sectional plan view of a rotary cutter according to a first embodiment of the present invention, Fig. 2 is a sectional view along line A-A in Fig. 1, Fig. 3 is a rotary cutter in Fig. 1, the stopper is in contact with the reel A plan view of the state where the upper cams are engaged, FIG. 4 is a plan view of a state where the stopper is guided by the lower cam of the reel in the rotary cutter of FIG. 1 , and FIG. 5 is a partially cutaway plan view of a second embodiment of the present invention, Fig. 6 is a sectional view along the B-B line in Fig. 5, Fig. 7 is a partial sectional plan view of the third embodiment of the present invention, Fig. 8 is a partial sectional plan view of the fourth embodiment of the present invention, Fig. 9 is a fifth embodiment of the present invention Partial sectional plan view of the embodiment, FIG. 10 is a partial sectional plan view of the sixth embodiment of the present invention, FIG. 11 is a view corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com