Ratchet wheel screwdriver

A screwdriver and ratchet technology, applied to screwdrivers, manufacturing tools, etc., can solve problems such as low locking force, failure, easy slipping or tooth chipping, etc., and achieve the effect of strong locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Regarding the techniques, means and effects used in the present invention, a preferred embodiment is given and described in detail with reference to the drawings.

[0034] Please refer to FIG. 1-FIG. 12 , which shows an embodiment selected by the present invention, which is for illustration purposes only, and is not limited thereto in patent application.

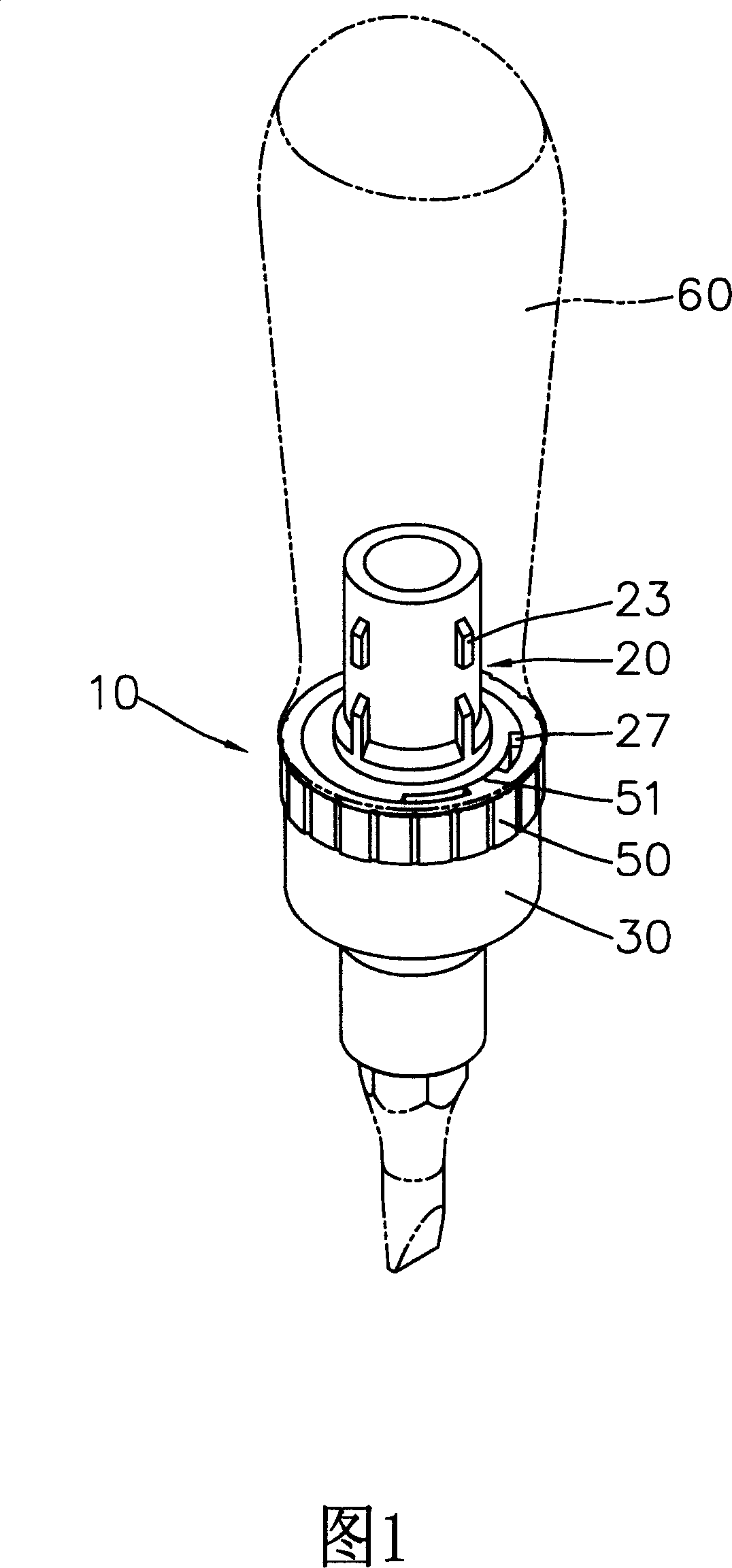

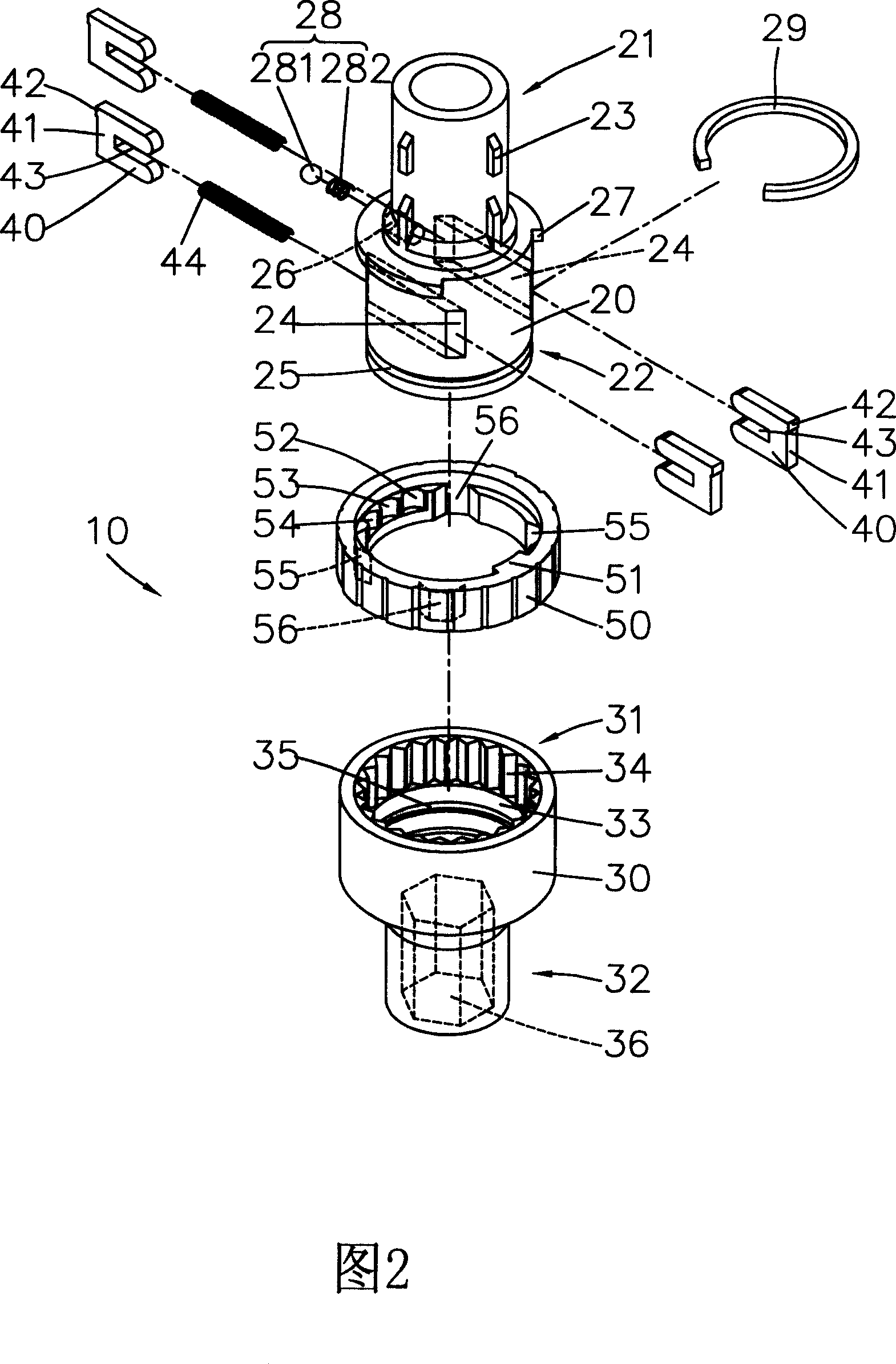

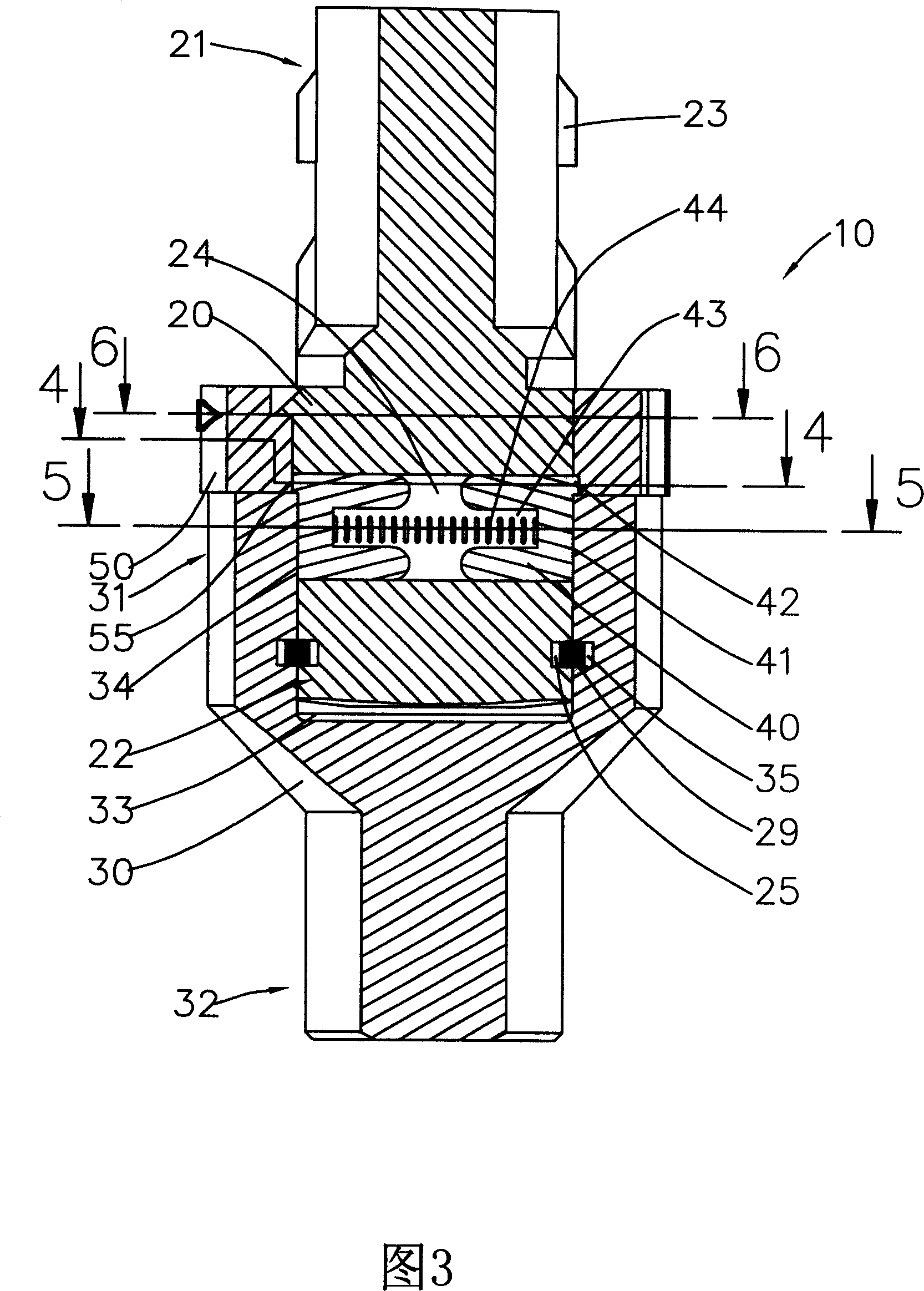

[0035] Referring to FIGS. 1 and 2 , according to the first embodiment of the present invention, the ratchet driver 10 includes a first body 20 , a second body 30 , four locking elements 40 and a reversing switch 50 . The second body 30 is rotatably pivoted at one end of the first body 20 , and the two locking members 40 are slidably disposed at the first body 20 and are controlled by the pivotally disposed at the outer edge of the first body 20 . The reversing switch 50 controls and selectively limits the rotation of the second body 30 .

[0036] The first body 20 includes a first end 21 and a second end 22, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com