Conducting wire protection mechanism

A wire protection and wire technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of wire cut lighting, light source wire cut, no light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

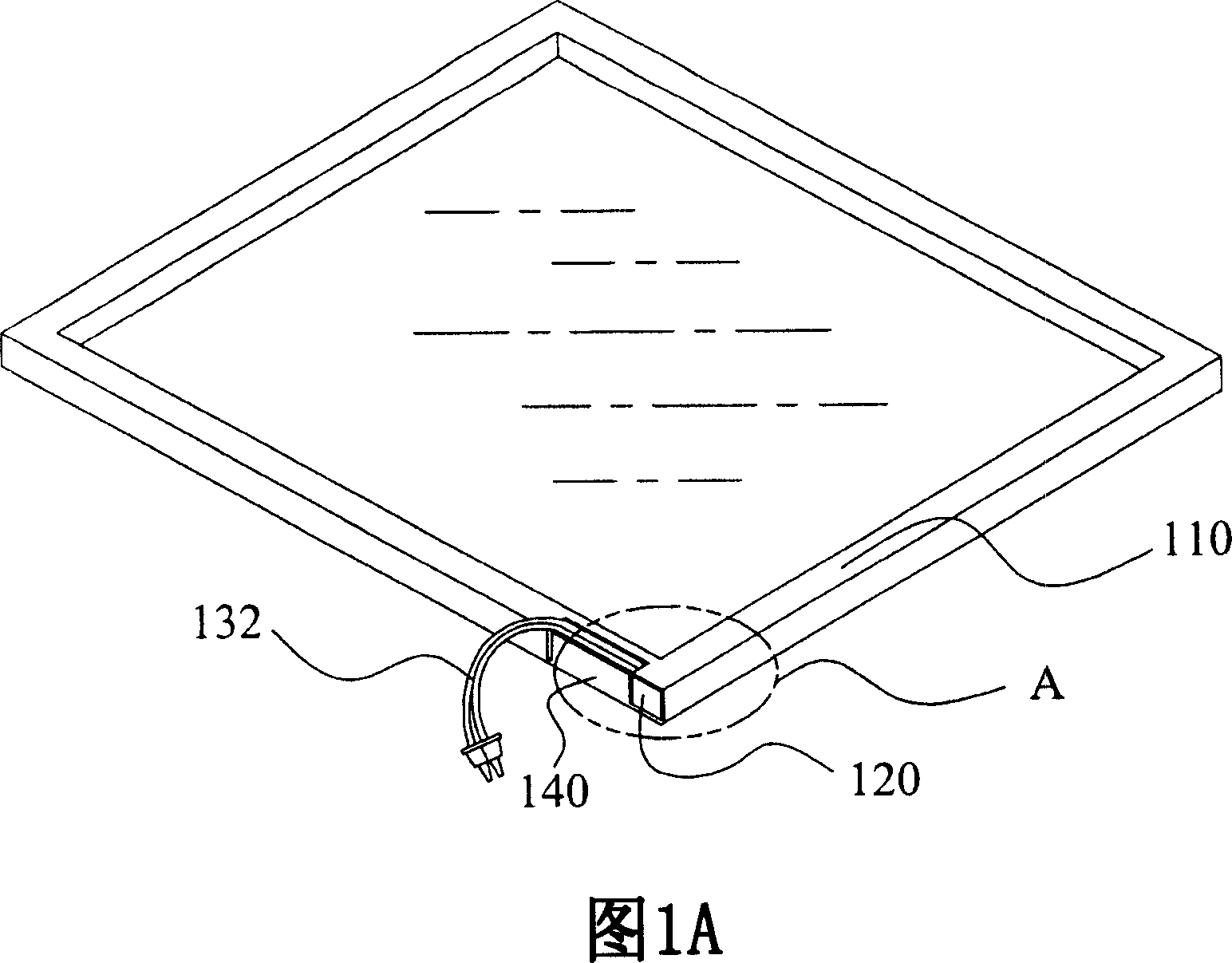

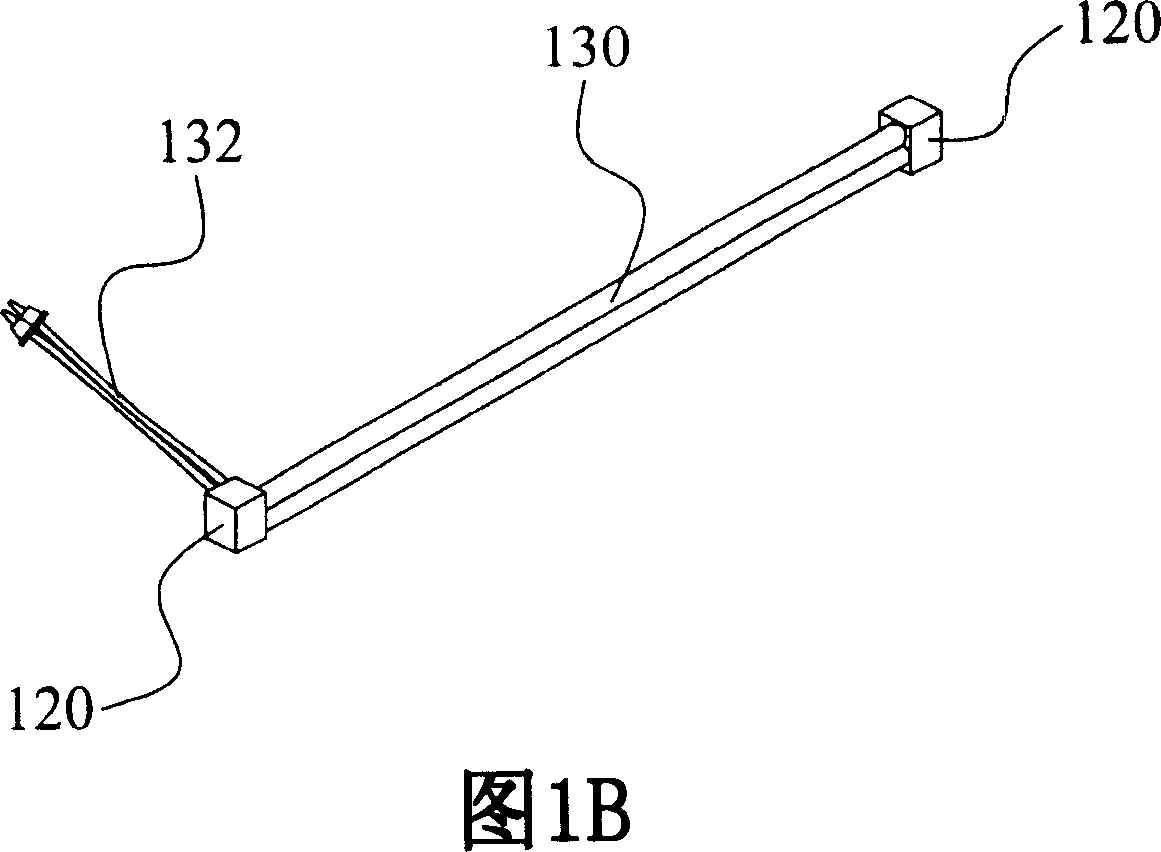

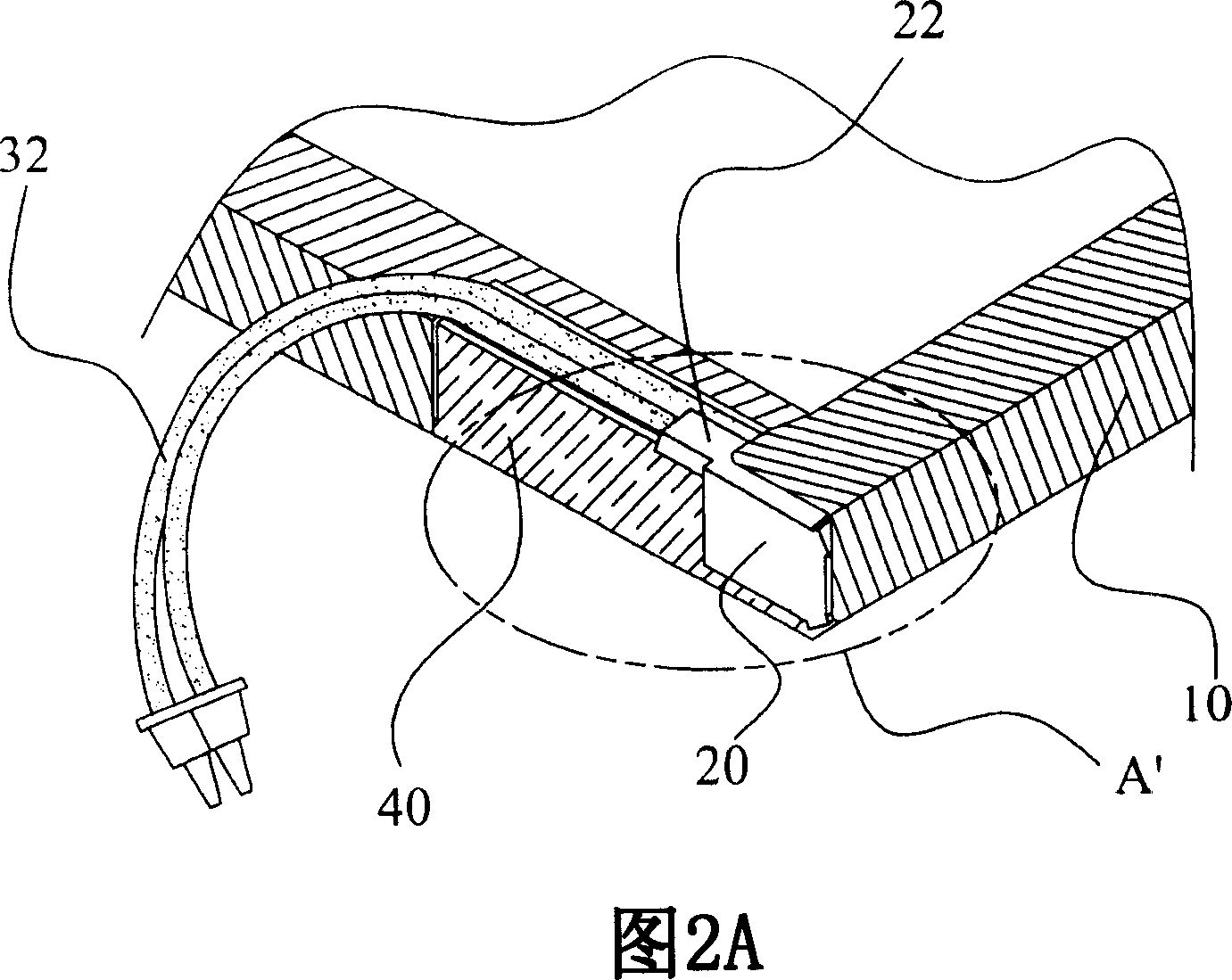

[0027] FIG. 2A and FIG. 2B are detailed schematic diagrams of outlet terminals of a backlight module according to an embodiment of the present invention. In this embodiment, the wire protection mechanism at the wire outlet A' of the backlight module includes a back plate 10 , a holding element 20 , a light source wire 32 and a buffer pad 22 . In the backlight module, the back plate 10 is used to arrange a light source 30 thereon, such as a cold cathode tube or a hot cathode tube, and the holding element 20 is used to fix and receive the light source 30 . The backplane 10 has an outlet A' located on one side of the backplane 10. The light source wire 32 is led out from the outlet end A' through the holding element 20. Wherein, a buffer pad 22 is disposed at the wire outlet A to separate the light source wire 32 from the edge of the back panel 10 .

[0028] Continuing the above description, in this embodiment, the material of the back plate 10 is metal, such as aluminum plate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com