Lotus type mold opening mechanism of glassware press

A technology of glassware and switching molds, which is applied in the direction of glass pressing, glass forming, glass manufacturing equipment, etc. It can solve the problems of monotonous style, difficulty in meeting aesthetic needs, and simple structure of glassware, so as to achieve good product quality and rich appearance , the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

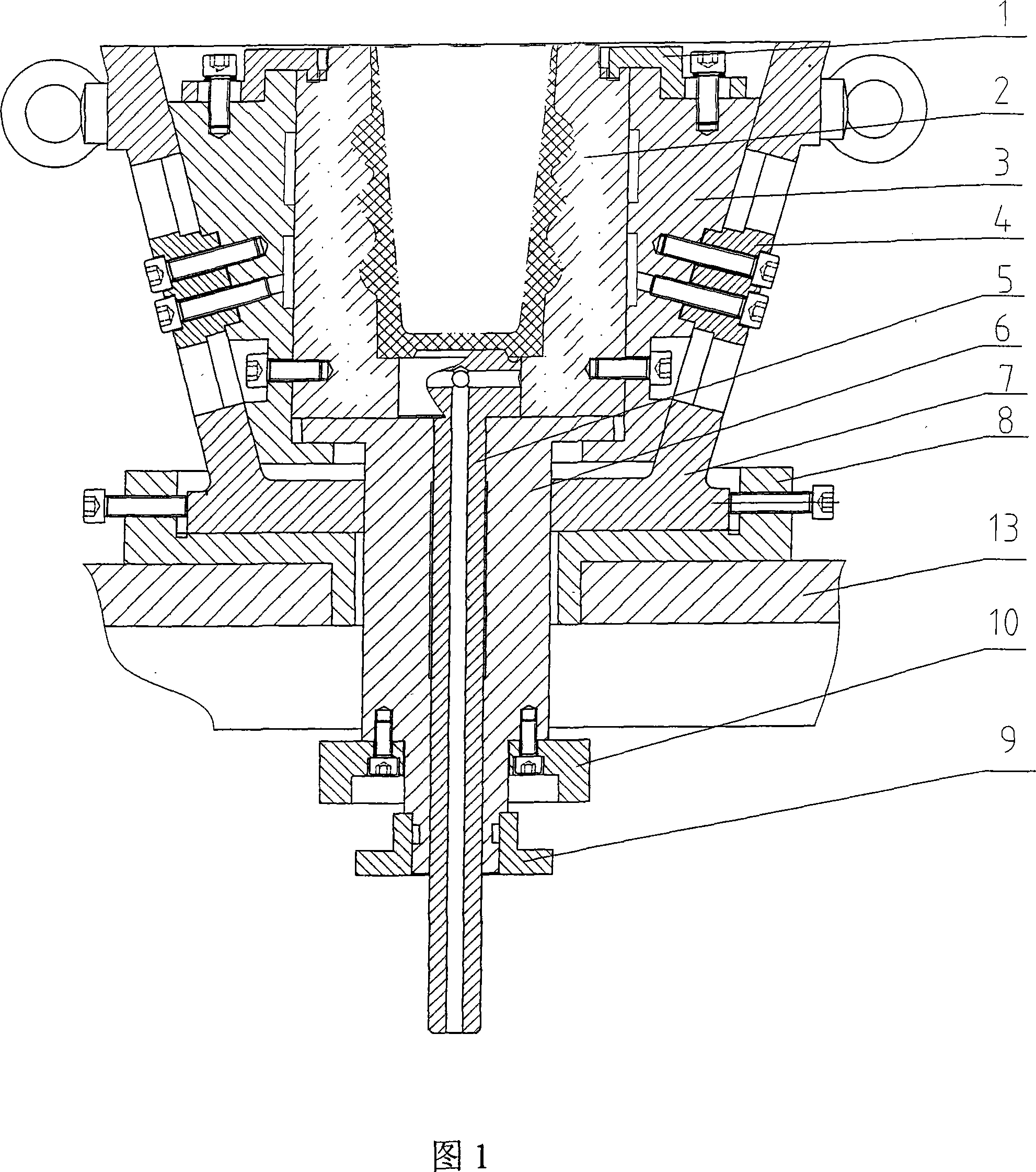

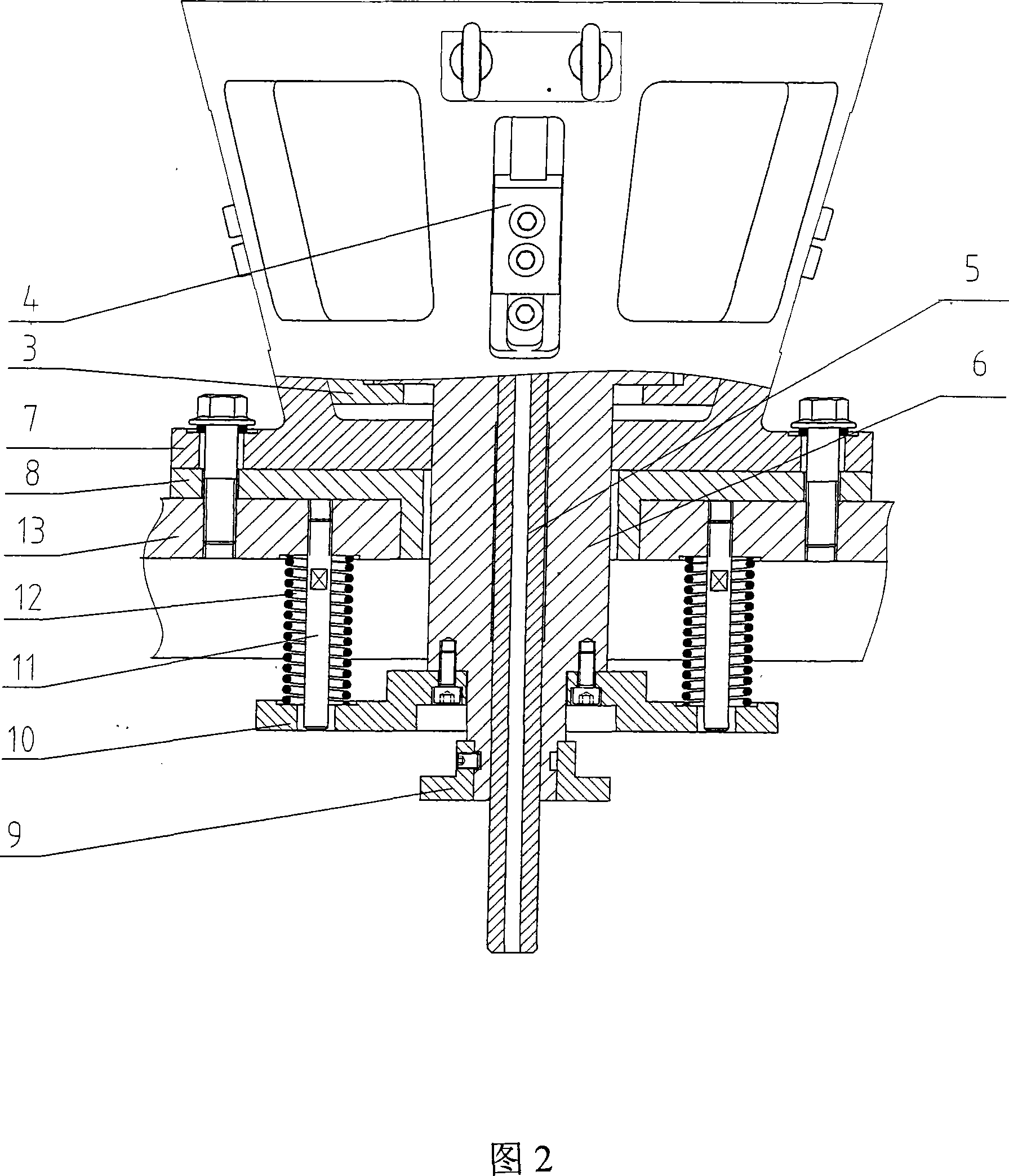

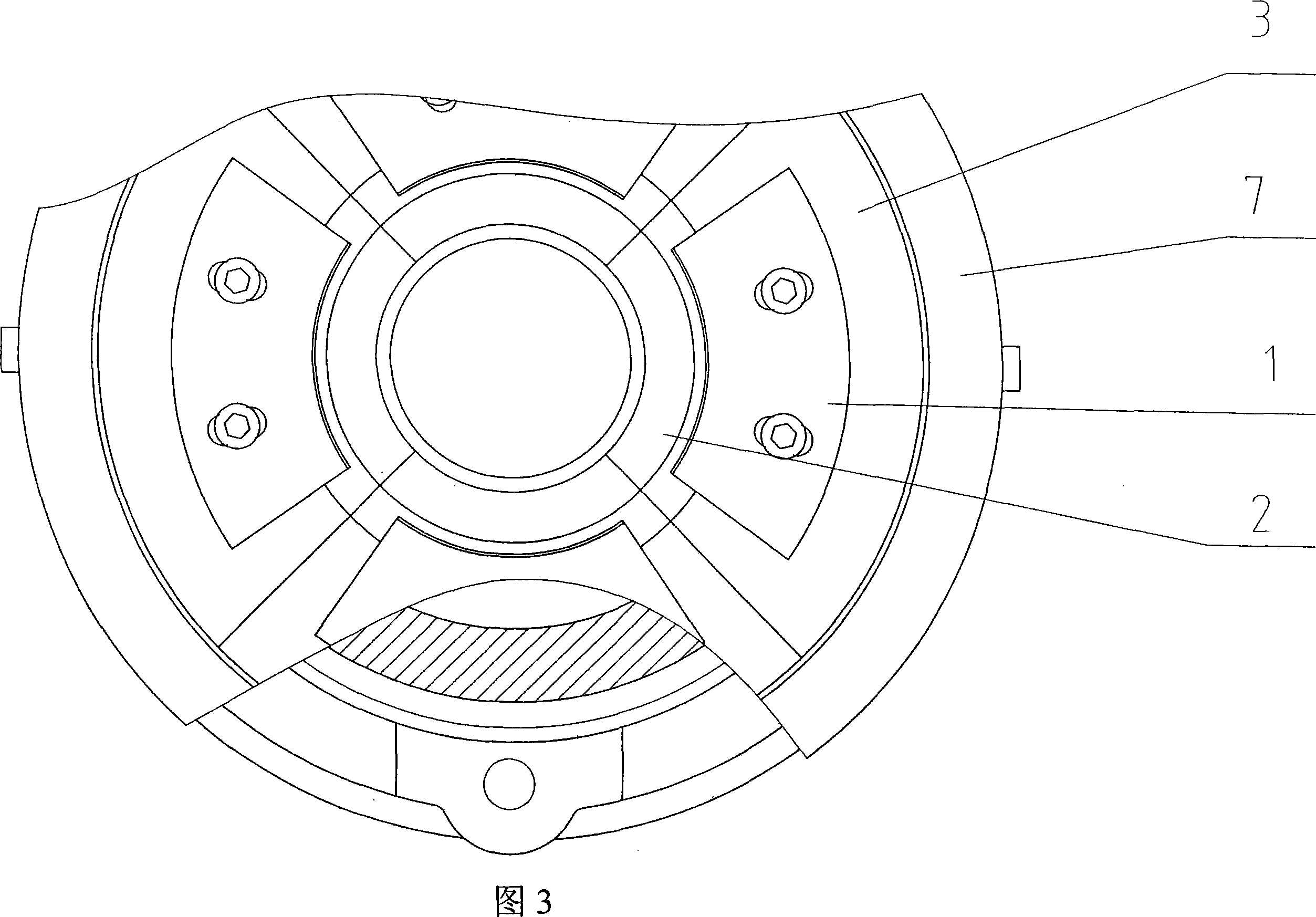

[0017] As shown in Figures 1 to 5, a lotus open-type switch mold mechanism in a glassware press is characterized by two parts: a switch mold mechanism and a slideway mechanism. The switch mold mechanism includes: mold upper platen 1, inner mold sleeve 3, slider 4, small ejector pin 5, large ejector pin 6, outer mold sleeve 7, mold adjusting seat 8, ejector pin bushing 9, spring seat plate 10, Spring guide column 11, spring 12;

[0018] Fig. 1 is a front view of the switch mold mechanism, Fig. 2 is a right view of the switch mold mechanism, and Fig. 3 is a top view of the switch mold mechanism. As shown in Figures 1 to 3: the outer mold cover 7 is directly above the mold adjustment seat 8, and the mold adjustment seat 8 is installed on each station hole on the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com