Anti-drop method for climbing iron tower of power transmission line

A power transmission line iron tower and anti-drop technology, which is applied to safety belts, life-saving equipment, etc., can solve the problems of high maintenance cost, unsatisfactory effect, inflexible use, etc., and achieve the effect of flexible use, promotion of safe production, and no need for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

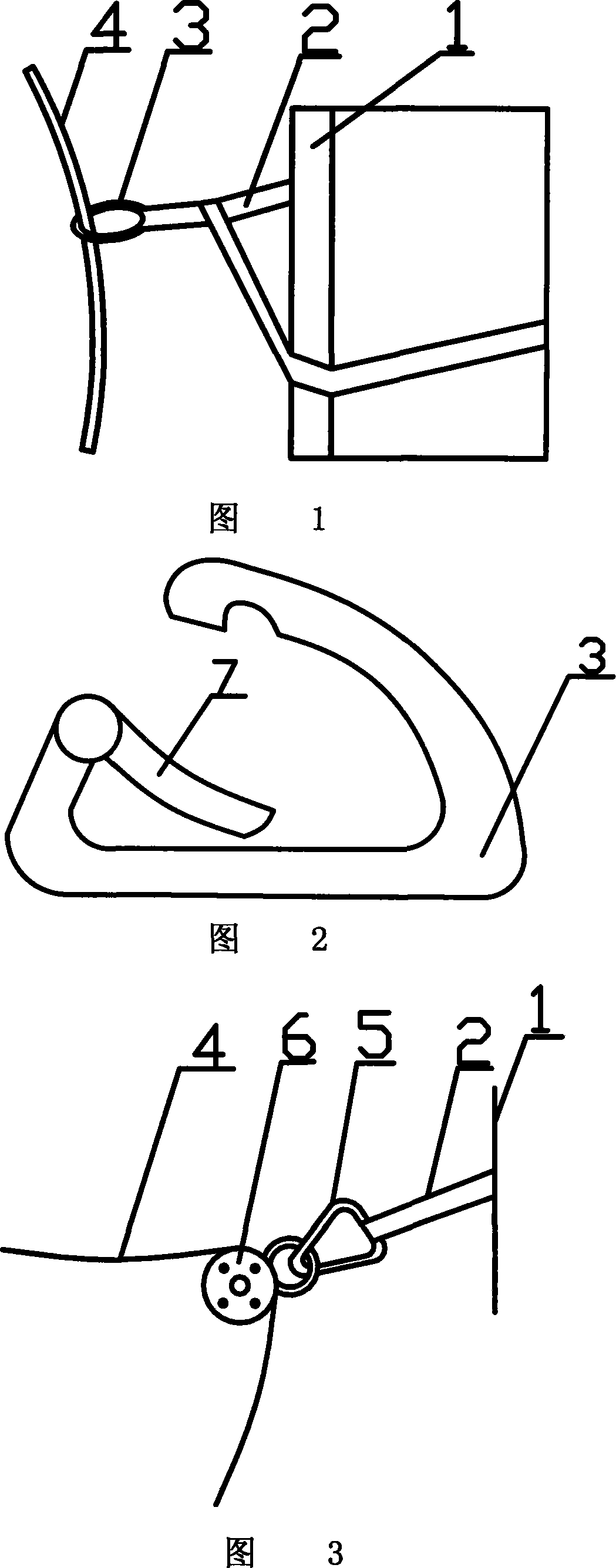

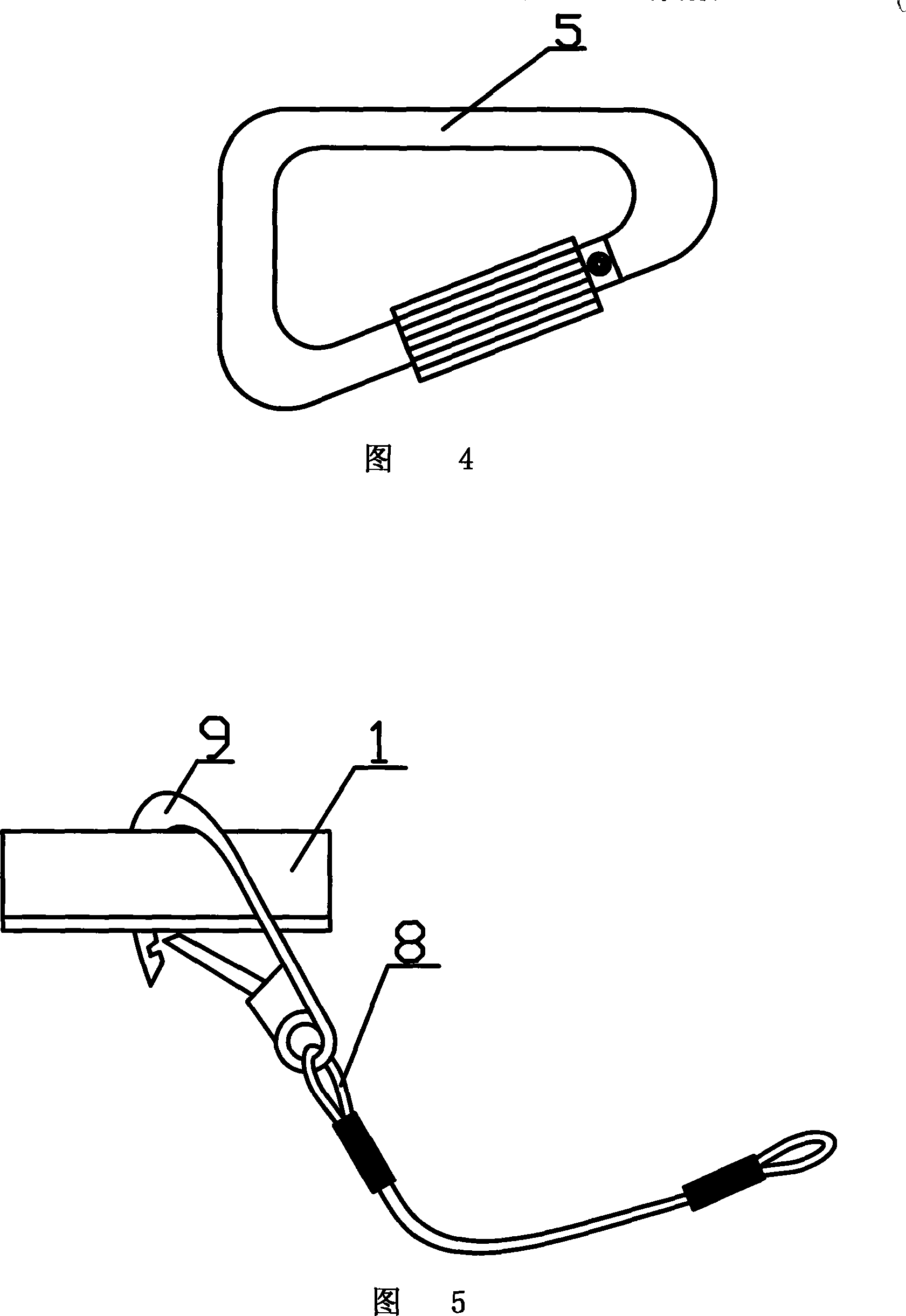

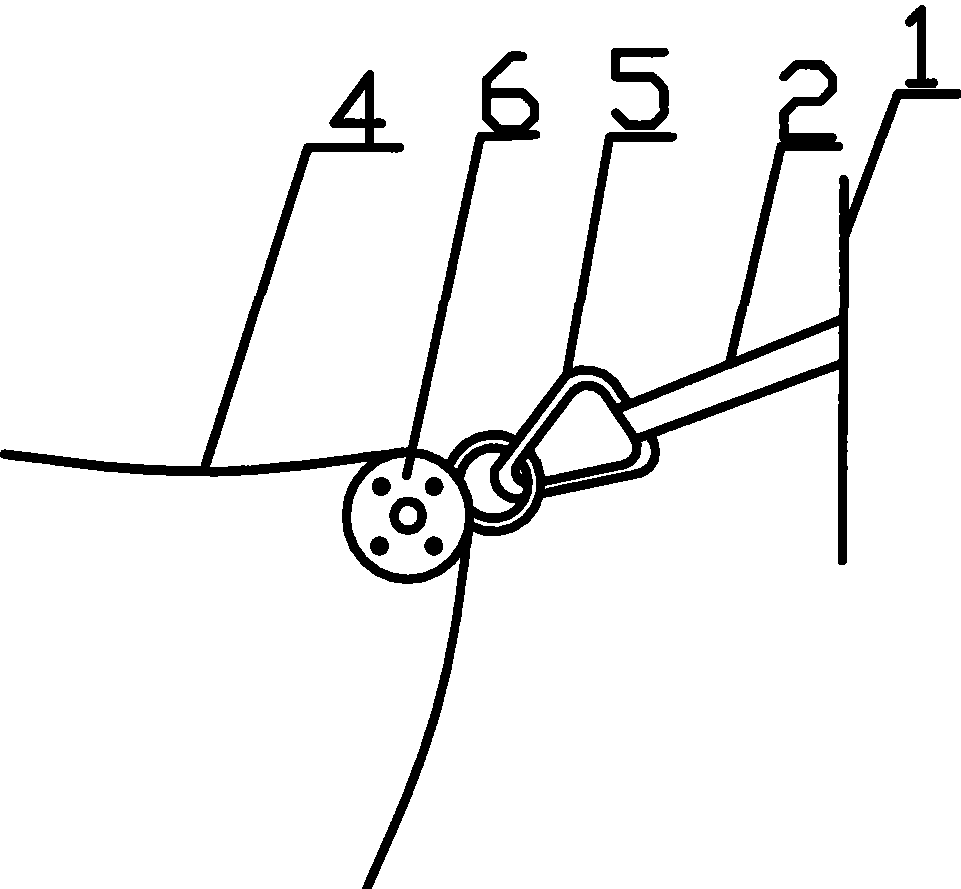

[0017] Example. A method for preventing falling in the climbing process of a power transmission line iron tower is characterized in that the tools used include a safety rope 8 (such as the JANE L50 produced by the French PETZL company), a full-body safety belt (such as the NEWTON C73 produced by the French PETZL company), Large hook 9 (such as MGOL110 produced by French PETZL company), small hook (such as M35SL produced by Italian CAMP company), headless rope 2 (such as SLING 16 produced by French BEAL company), such as Figure 4 The shown triangular silk lock safety buckle 5 (such as the LOCKM20 produced by the French PETZL company), such as figure 2 The pear-shaped safety buckle 3 shown (i.e. the pear-shaped quick padlock, such as the SPIRIT M15 produced by the French PETZL company), the trolley 6 (such as the FIXEP05 produced by the French PETZL company), the anti-drop device (such as the ASAP B71 produced by the French PETZL company) ), main rope (like the LOOP10.5 produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com