Driving mechanism for mobile door lock

A driving mechanism and door lock technology, applied in the field of sliding door locks, can solve the problems of heavy and stiff hand feeling, complex structure, easy wear, etc., and achieve the effects of reducing mechanical friction, good hand feeling, and simple lock body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

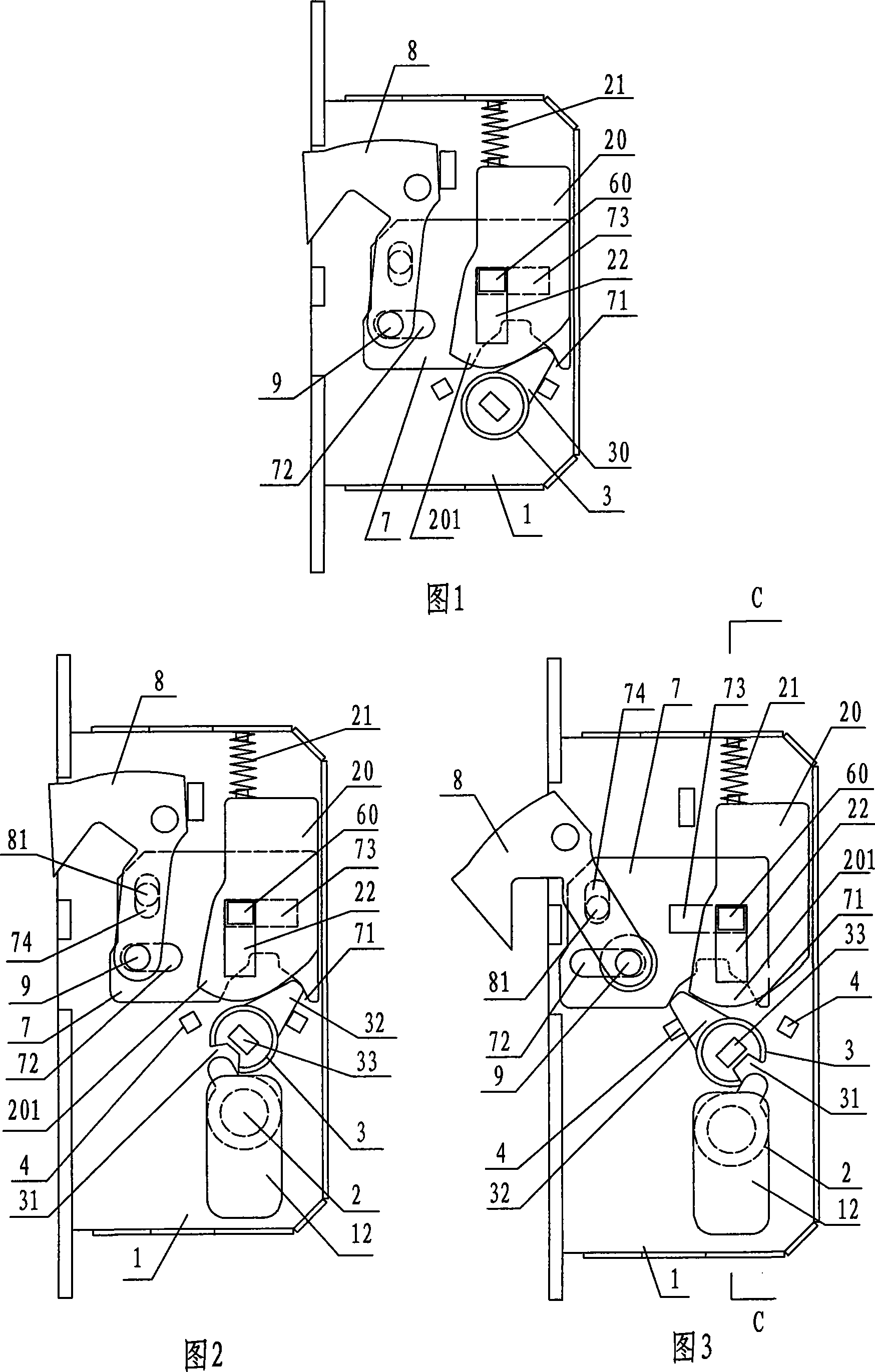

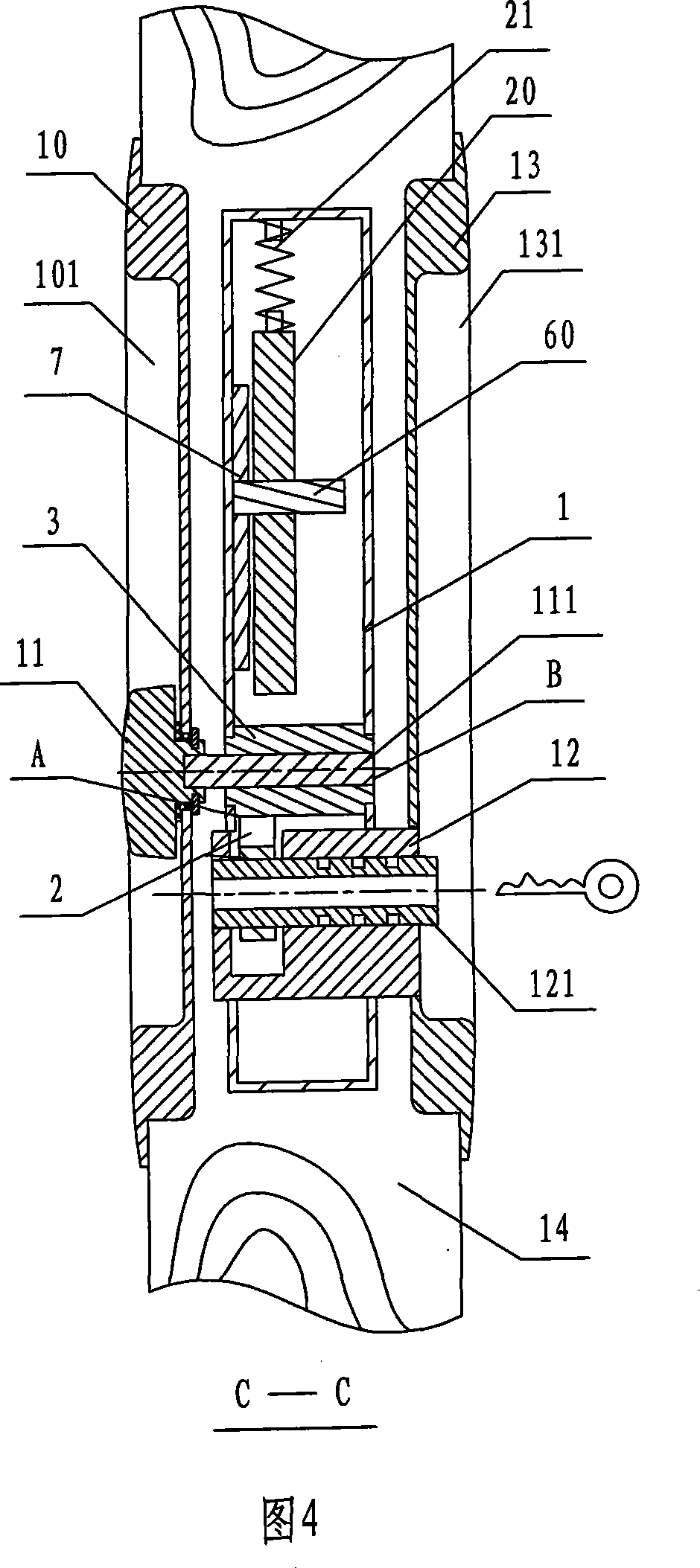

[0033] As shown in Figures 2, 3, and 4, a driving mechanism for a sliding door lock includes a lock case 1, a toggle wheel 3 accommodated in the lock case 1; and a lock cylinder 12 fixed in the lock body, The axial tail end of the lock cylinder 12 is provided with a shift fork 2 that can rotate coaxially with the lock cylinder 121, and a shift fork opening 31 is also provided on the side of the toggle wheel 3; The misalignment of the central axis of the wheel 3 is parallel to the central axis of the inner knob 11 and separated by a certain distance. On the side of the toggle wheel 3 and at a symmetrical position of 180 degrees with the toggle arm 32, a shift fork opening 31 is provided, and the shift fork 2 of the lock cylinder 12 stretches into the shift fork opening 31 to form a transmission connection. The shape and size of the shift fork opening 31 on the toggle wheel 3 and the shift fork 2 are compatible with each other. When the lock cylinder 12 is turned, the transmissi...

Embodiment 2

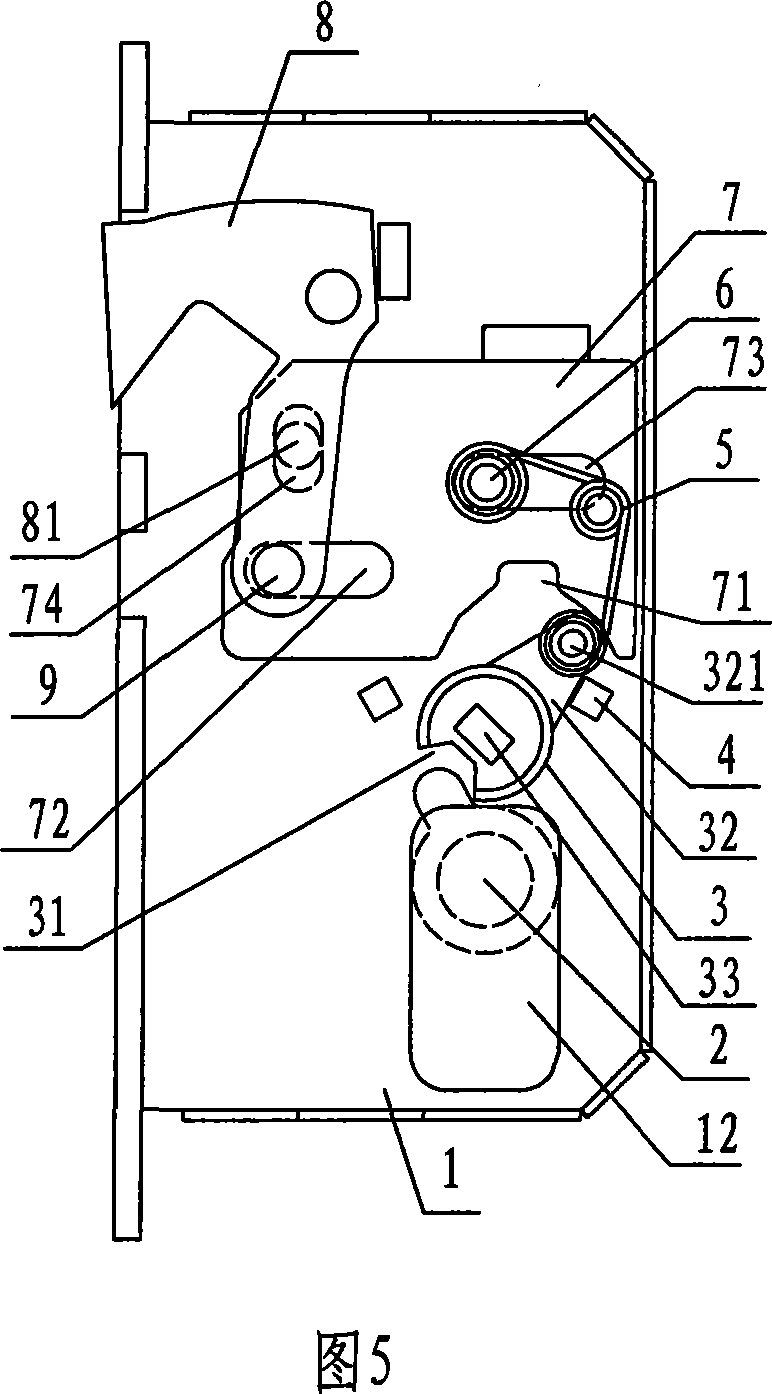

[0044] As shown in Figures 5, 6, and 7, the difference from Embodiment 1 is that the driving mechanism of the sliding door lock includes three coils of special-shaped springs 5, the spring positioning shaft 6 fixed on the lock housing 1, and the three coils of special-shaped springs 5 are fixed. It is connected between the toggle arm 32 and the spring positioning shaft 6, thereby replacing the positioning plate guide shaft 60, the limit arm 20 and the limit arm return spring 21 in the prior art with three rings of special-shaped springs 5. The position-limiting mechanism of toggle wheel 3 and positioning plate 7.

[0045] The spring positioning shaft 6 is located in the area where the positioning plate 7 is located, and can also be arranged outside the area where the positioning plate 7 is located. For the sake of simplicity in structure, it is preferable to arrange the spring positioning shaft 6 in the area where the positioning plate 7 is located, and use the spring positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com