Device for the selective and progressive locking of metal containers

A metal container and locking device technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of not being able to ensure the correct, stable and constant alignment of the container itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

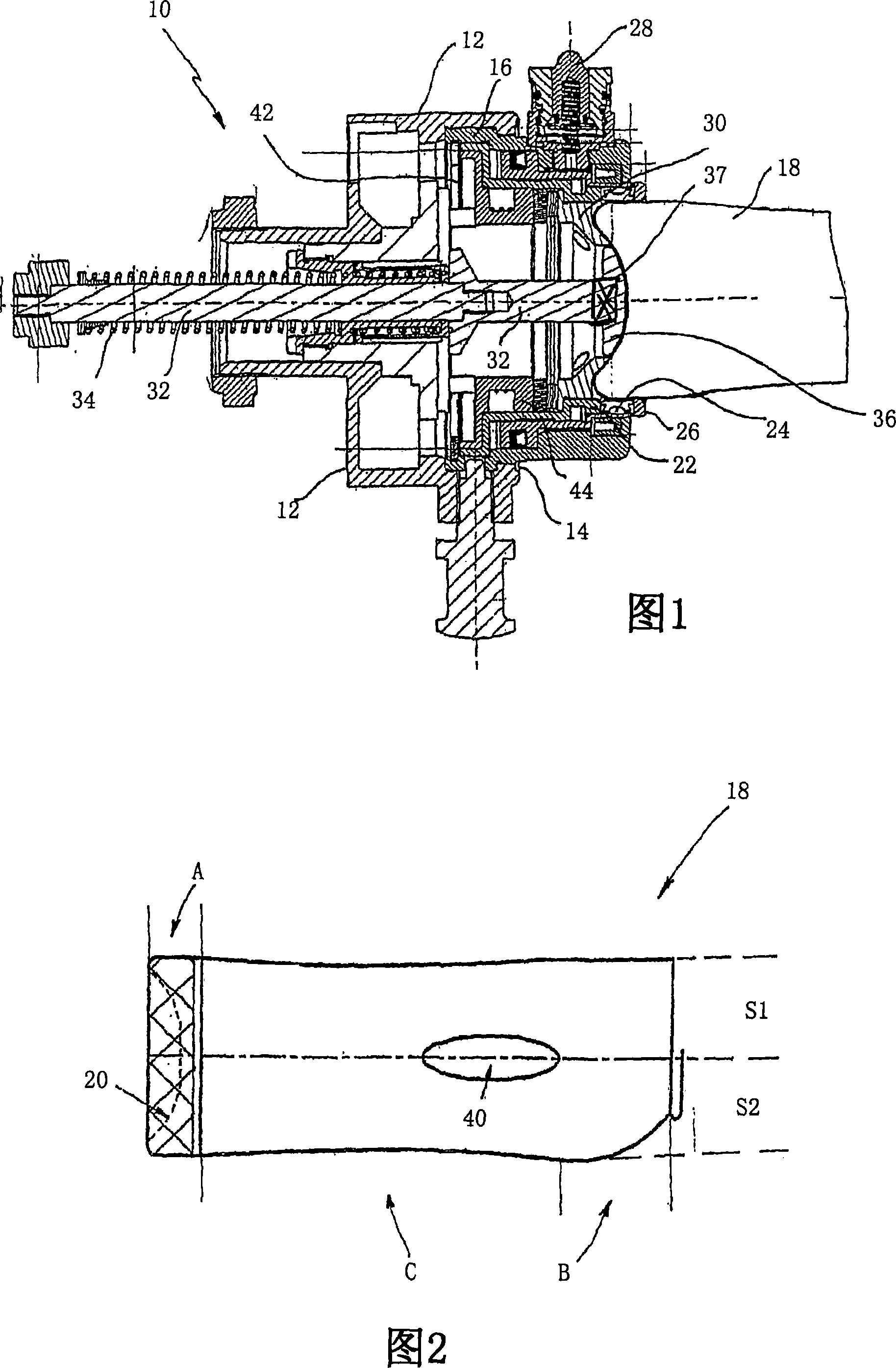

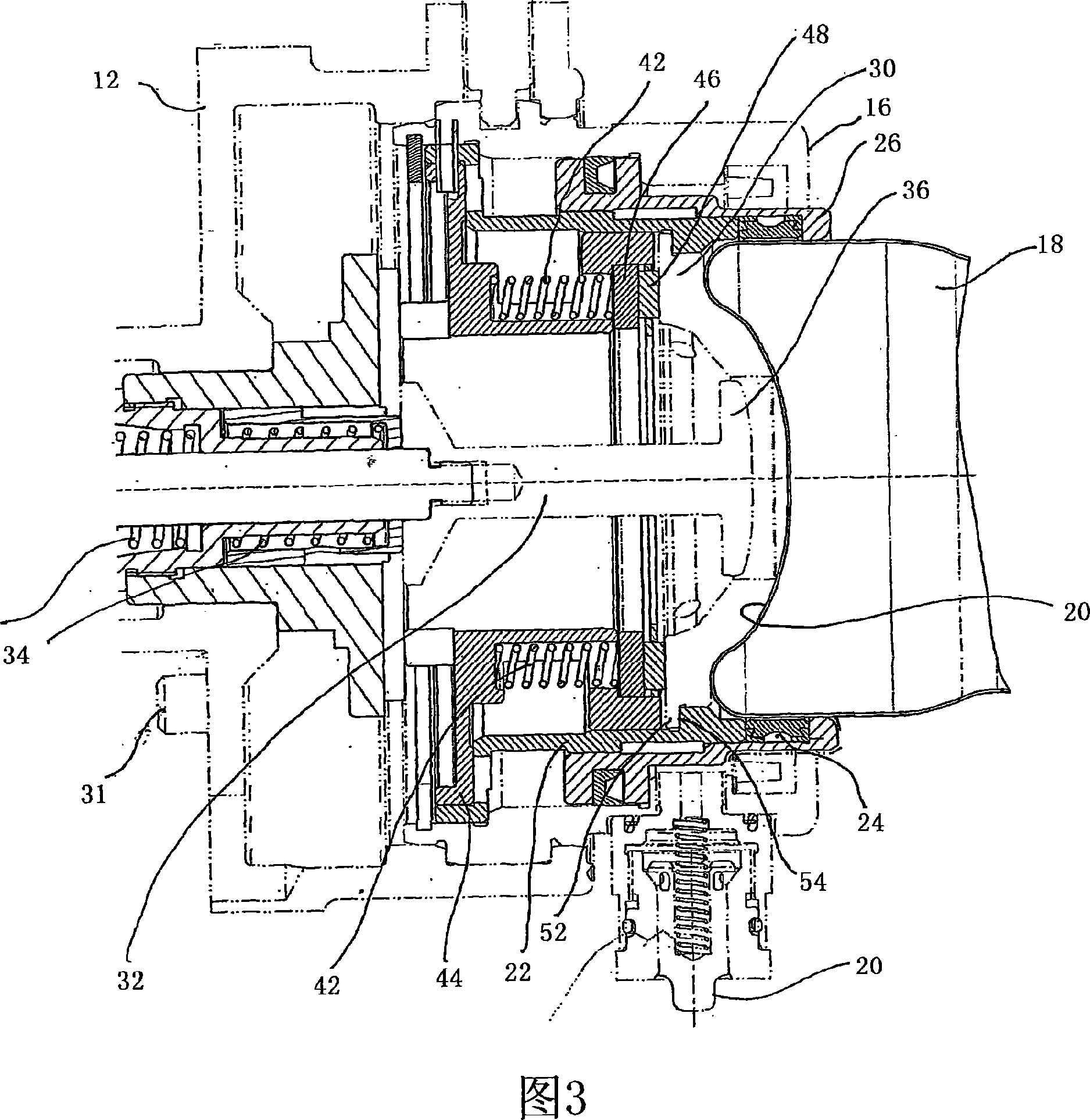

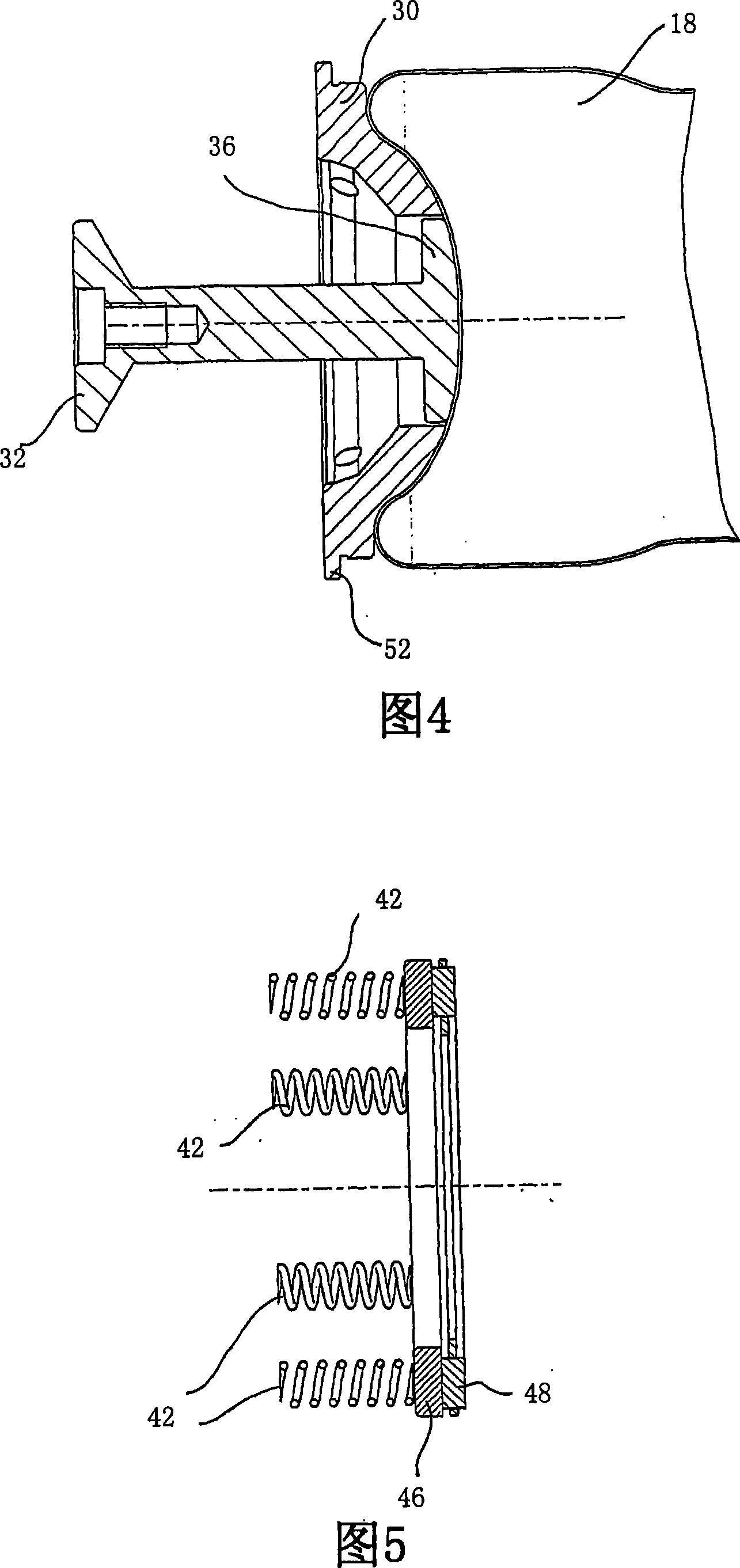

[0024] With reference to the above-mentioned figures, the selective and improved locking device of the metal container of the present invention, indicated by the reference number 10 in the accompanying drawing 1, comprises: a circular planar support 12 defined in the container body 16 At one end of a seat mouthpiece 14, which protrudes on the front side from the stand itself towards the container so as to extend in the side surface forming an Intervention.

[0025] Said container is indicated with 18 in accompanying drawing 1, and also shows with side view in accompanying drawing 2; Said larger shaped top half "S1" and bottom half "S2" are provided, on which the tapering operation described below is also carried out in the area close to the interface. As shown in Figure 2, the container 18 extends to a substantial portion of the side surface, preferably encompassing the entire area comprised between the bottom and the opposite top, spaced from the bottom by a limited stroke in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com