Diverter valve and channel for brewed beverage maker

一种制造机、转向阀的技术,应用在流体通道,转向阀领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

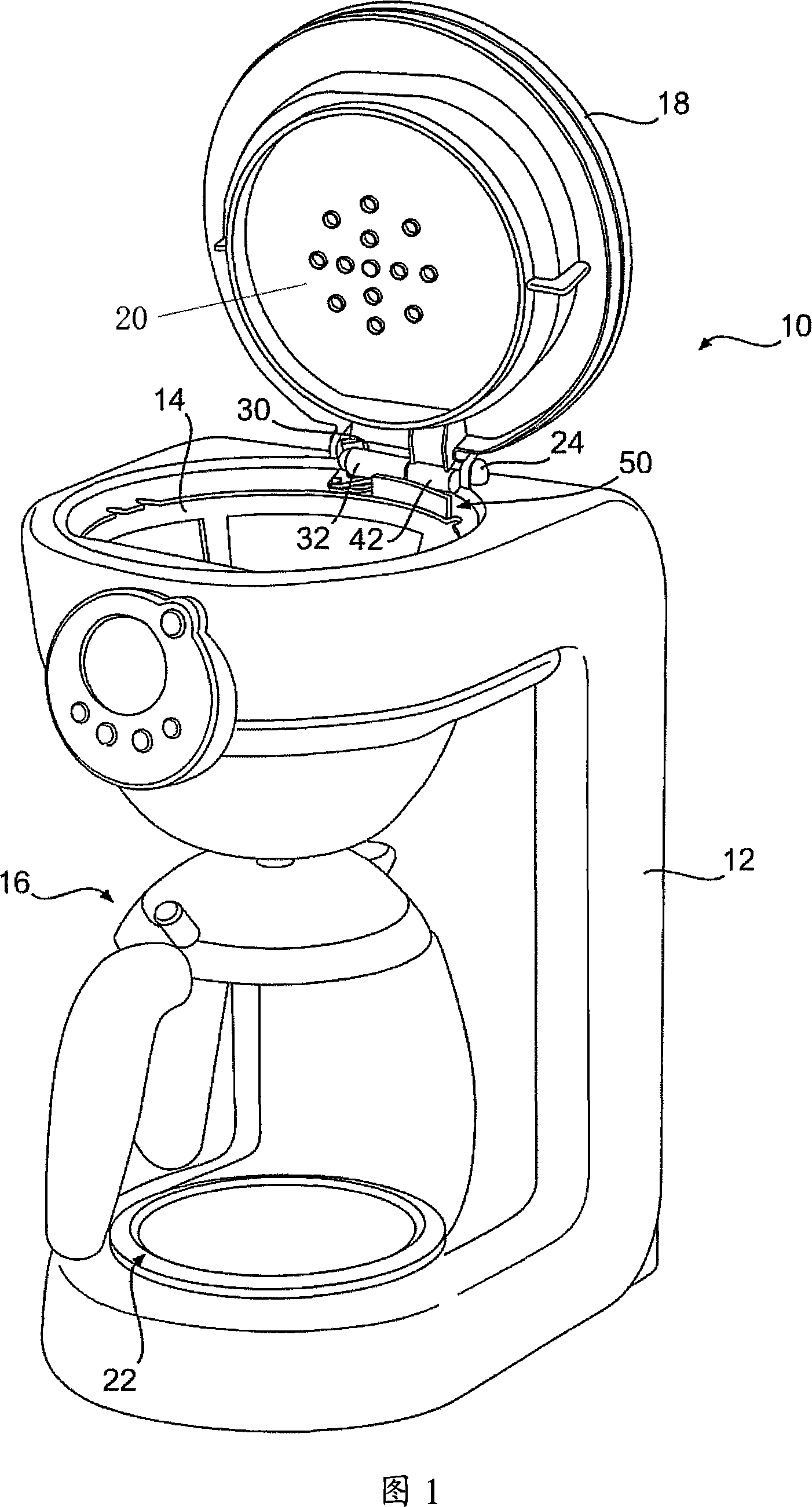

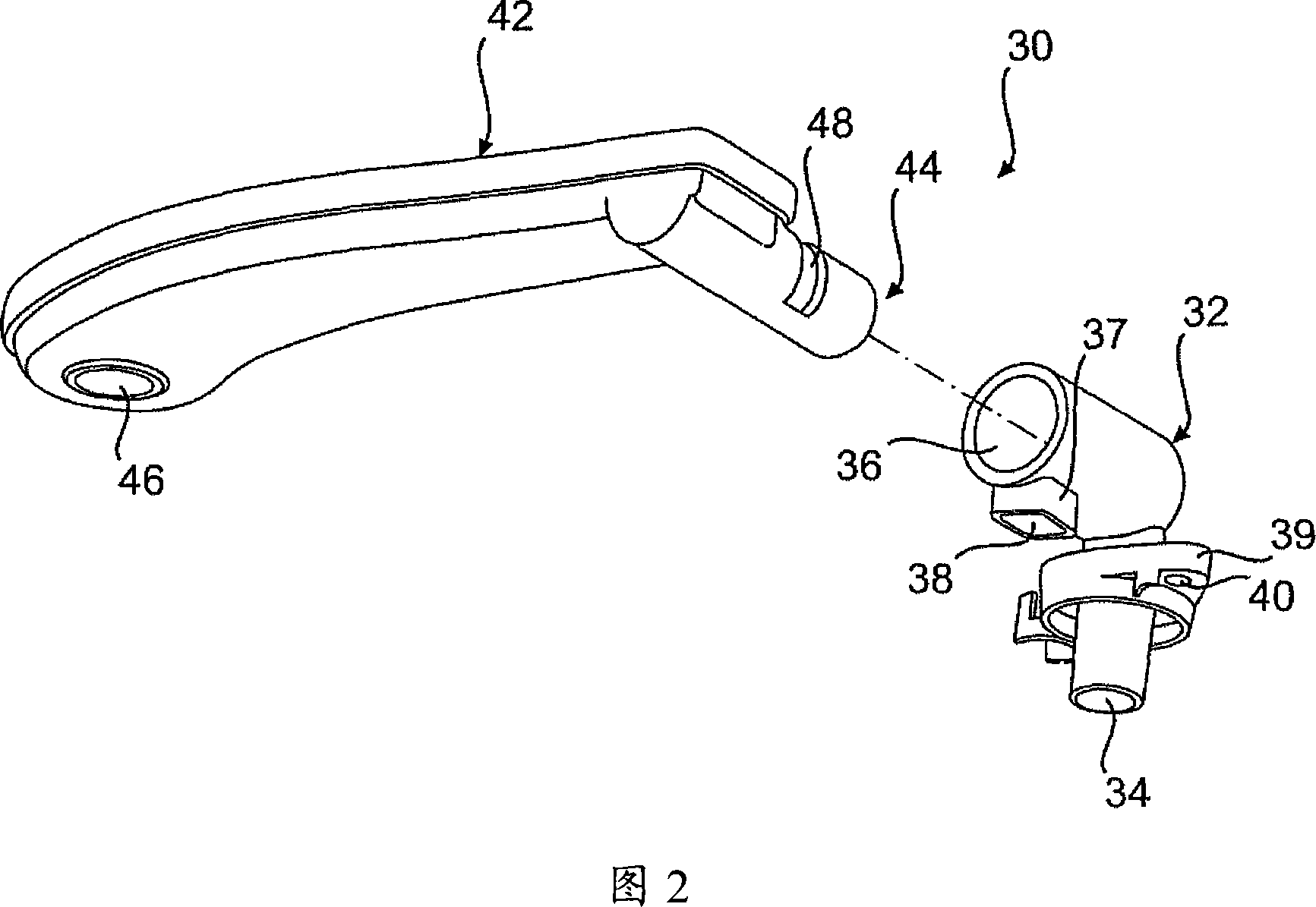

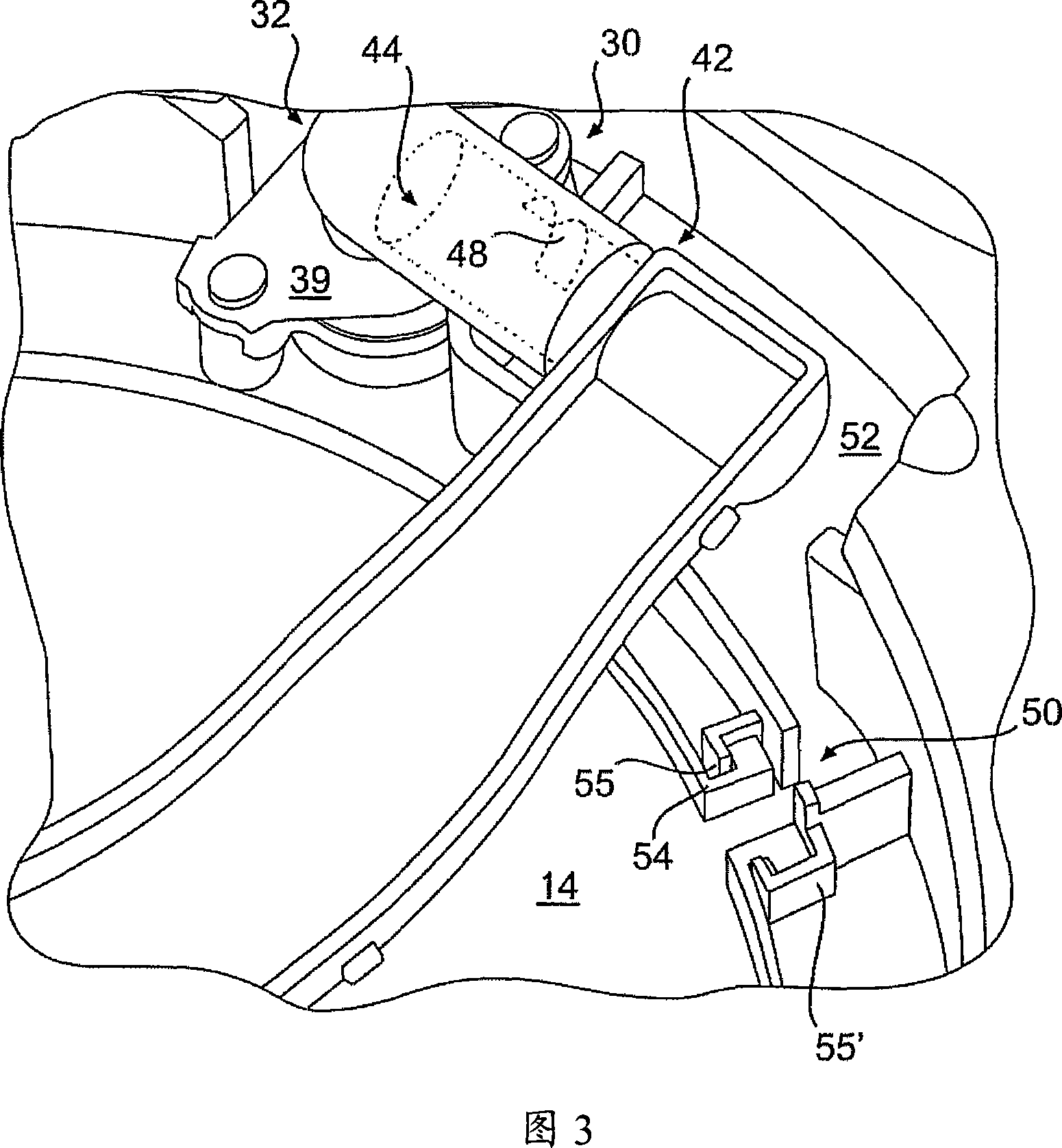

[0018] A diverter valve assembly and fluid channel for use with a brewed beverage maker according to the present invention provides an improved method and apparatus for reducing the risk of accidental ejection of heated fluid from the brewed beverage maker. The diverter valve and channel configuration can also operate with brewed beverage makers that include an integral or removable fresh water reservoir.

[0019] Like a traditional automatic drip coffee machine, the brewing cycle consists of several steps in sequence. First, fresh water is heated in a hot water heater. Second, the heated water goes through the hot water pipe to the diverter valve. If the diverter valve is closed, the hot water passes through the diverter valve and then into the shower head placed above the filter basket. The filter basket holds insoluble substances, such as ground coffee. The heated water is then passed through the insoluble matter, through the filter and through the filter basket. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com