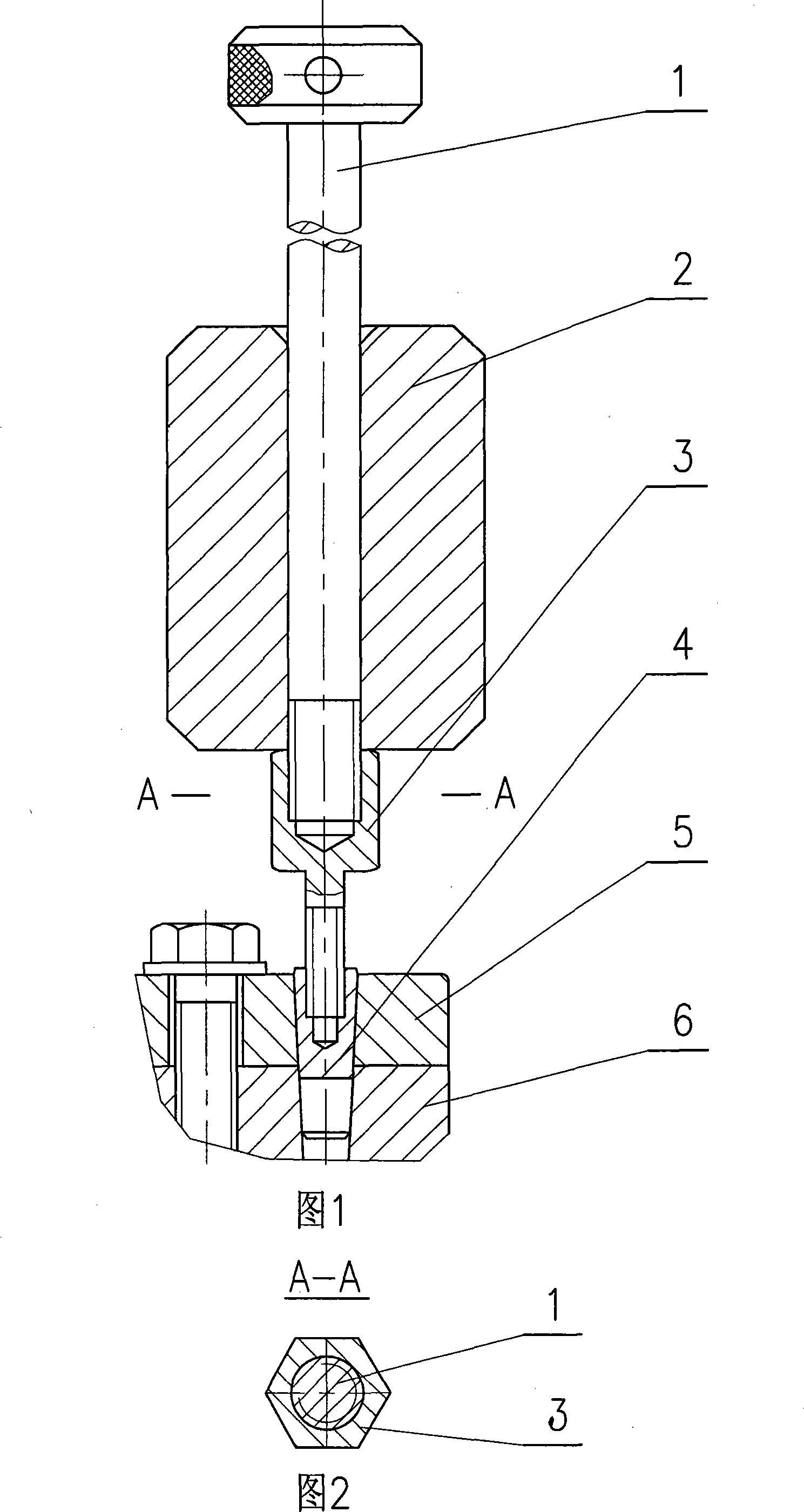

Inner screw taper pin dismounting tool

A technology for dismantling tools and internal threads, which is applied in the direction of manufacturing tools and hand-held tools, etc. It can solve the problems of small thread diameter, thread damage, unsuitable for disassembly of internal thread taper pins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] With reference to the accompanying drawings, the slide hammer 2 is mounted on the small cylinder of the pin puller rod 1, which is a fit with a larger gap. Generally, the hole of the slide hammer 2 is 1 to 2 mm larger than the small cylinder of the pin puller rod 1. The upper end of the hole where the slide hammer 2 cooperates with the pin puller bar 1 small cylinder has a chamfer. For the convenience of operation, the large end cylinder of pin puller rod 1 and the surface of slide hammer 2 cylinders are knurled. Pull head 3 is tightened on the stud of pin puller bar 1 small cylinder end, and pull head 3 big ends are regular hexahedron, and its radial cross section is consistent with the radial cross section of the hexagonal nut that its internal thread size is identical. The small end of the puller 3 is the same stud as the thread of the internally threaded tapered pin 4 screw holes, and the large end cylinder of the pin puller rod 1 has a hole that is vertical and pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com