Derusting machine for edge beam sections of sealing-tape machines

A technology of descaling machine and tape machine, which is applied to conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of affecting the production progress of the enterprise's production goals, unable to meet the needs of underground production, and the labor intensity of employees. The effect of mine repair and waste utilization, compact structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

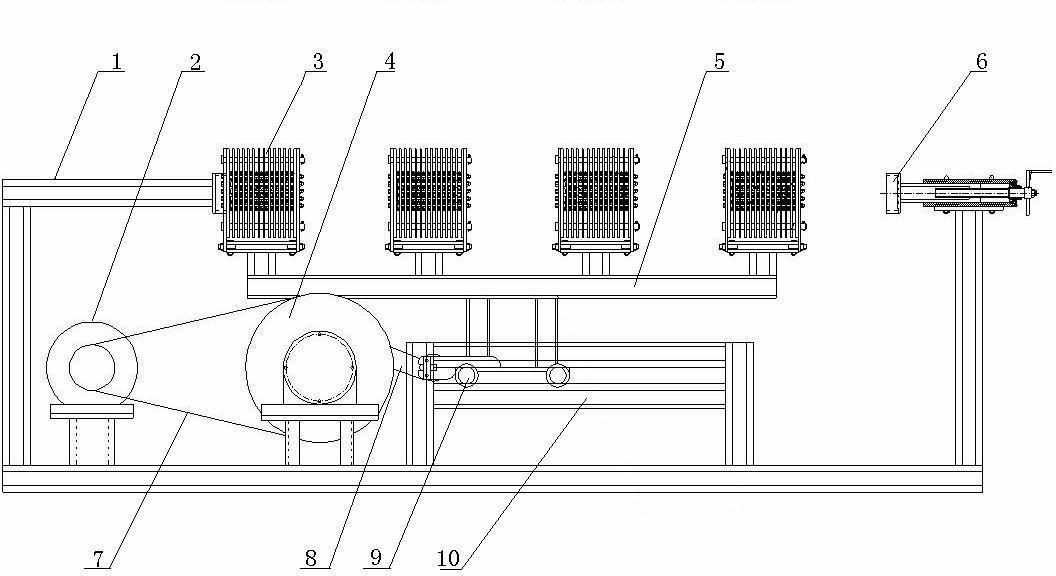

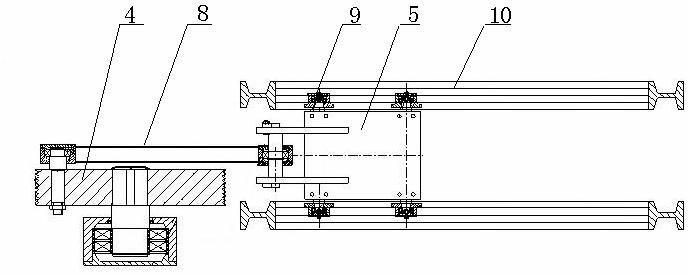

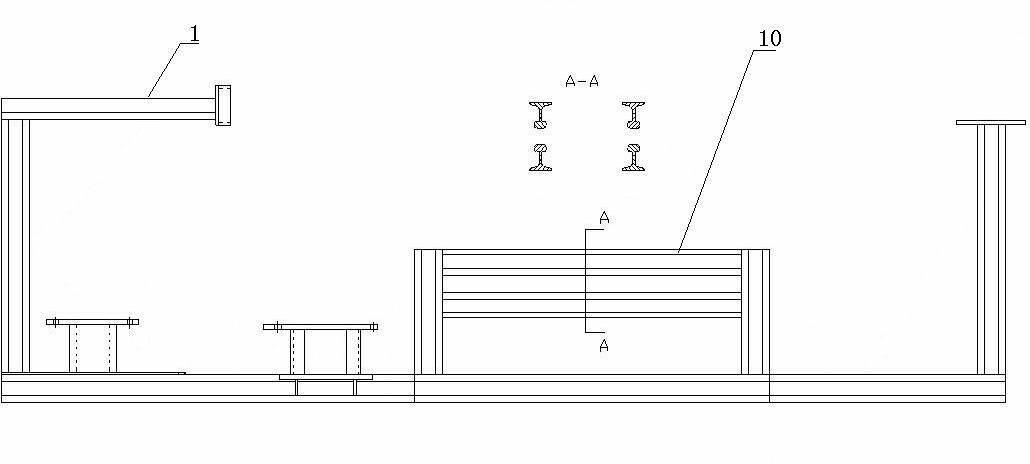

[0017] Specific implementation methods: such as figure 1 , figure 2 As shown, a belt machine side beam profile derusting machine includes a support frame 1 for fixed support, and the support frame 1 is provided with a derusting actuator and a driving mechanism. The bottom of the support frame 1 is fixed with two rows of slide rails 10, and the support frame 1 at one end of the slide rails 10 is fixed with a crank transmission mechanism; the crank transmission mechanism is connected with the drive motor 2 through 8 belts 7, and the model of the drive motor 2 is selected YB200L-8 type, the power is 15KW, and the speed is 730r / mm. Derusting executive mechanism comprises derusting pulley 5. Such as Figure 4 As shown, several pulleys 9 are provided on both sides of the pulley 5, and the pulleys 9 cooperate with the slide rails 10 on the support frame 1 to slide, and the stroke is 500 mm. The crank transmission mechanism includes a driven pulley 4, the edge of the rotating sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com