Vehicle wheel

A technology of wheels and spokes, which is applied in the field of fastening and connection components of wheels, can solve the problems of no use value, difficulty in locking the rotation sleeve, and inability to take it out from the first rotation stopping hole, etc., and achieve a good locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

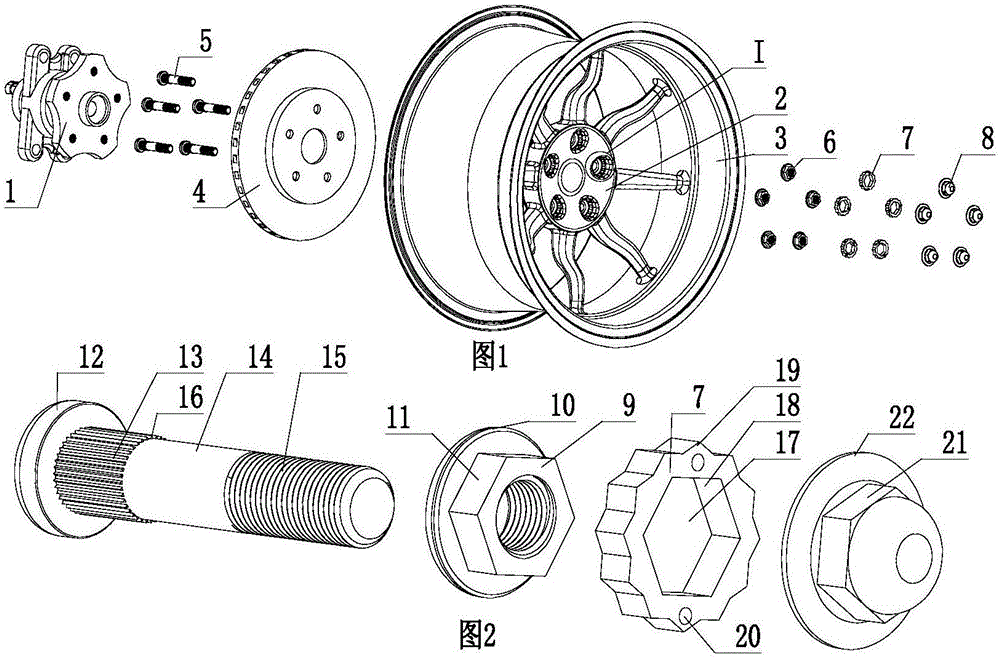

[0105] Such as Figure 1 to Figure 5 As shown, a wheel includes a hub 1, a spoke 2, a rim 3, a brake 4, and multiple sets of fastening and connecting components.

[0106] The fastening connection assembly includes a screw rod 5, a lock nut 6, an anti-rotation sleeve 7, and a stopper for the anti-rotation sleeve. The stopper of the anti-rotation sleeve is a blocking nut 8.

[0107] The lock nut 6 includes a regular hexagonal anti-rotation portion 9 , a cylindrical abutting portion 10 protruding radially from the anti-rotation portion 9 , and an end surface of the cylindrical abutment portion 10 transitions with a circular arc on the side. The six anti-rotation planes on the outer periphery of the anti-rotation portion 9 form six first anti-rotation portions 11 arranged in the circumferential direction. A threaded through hole is provided at the axial center of the lock nut 6 .

[0108] The screw rod 5 includes a resisting portion 12, an anti-rotation shaft 13, a polished rod...

Embodiment 2

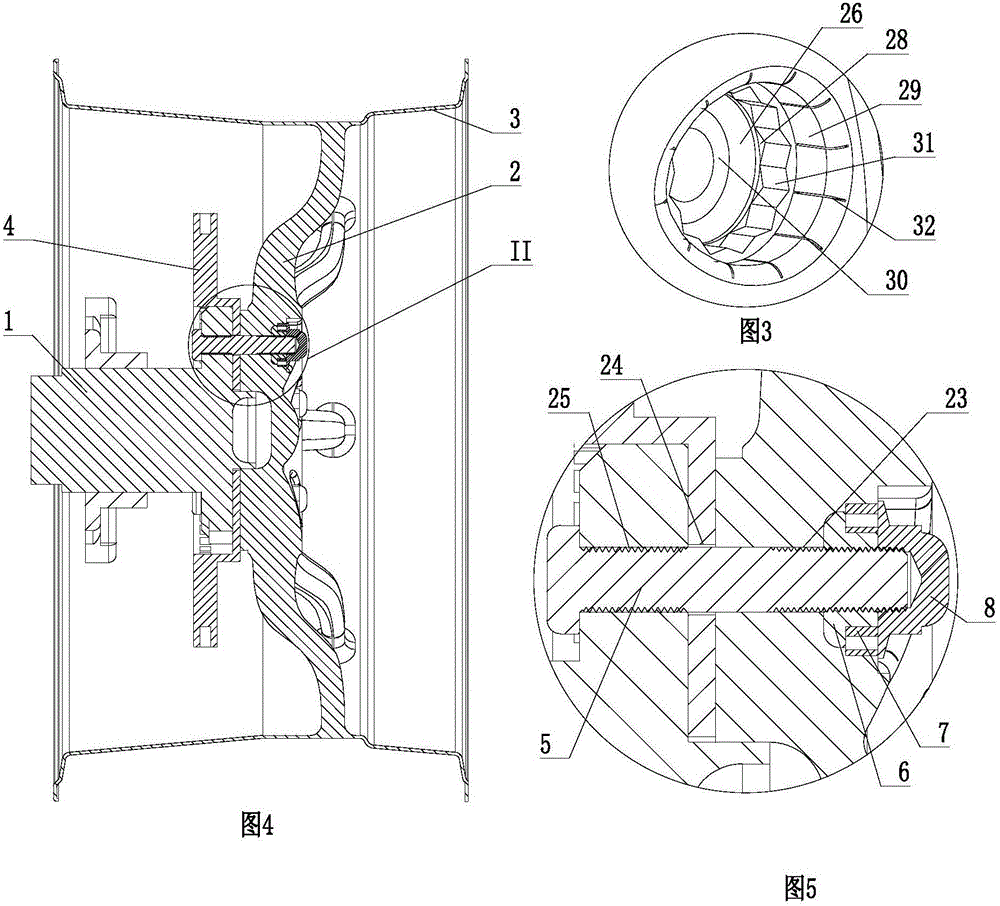

[0115] Such as Figure 6 to Figure 10 As shown, a wheel includes a hub 50, a spoke 51, a rim 52, a brake 53, and multiple sets of fastening and connecting components.

[0116] The fastening connection assembly includes a screw rod 54, an anti-rotation sleeve 55, and a stopper for the anti-rotation sleeve. The stopper of the anti-rotation sleeve is a resisting nut 56 .

[0117] The screw 54 includes a first external thread portion 57 , a cylindrical resisting portion 58 , a regular hexagonal anti-rotation portion 59 , and a second external thread portion 60 arranged in sequence. The resisting portion 58 protrudes radially from the first external thread portion 57 and the anti-rotation portion 59 , and the anti-rotation portion 59 radially protrudes from the second external thread portion 60 . The six anti-rotation planes on the outer periphery of the anti-rotation portion 59 form six first anti-rotation portions 61 arranged in the circumferential direction. The outer periphe...

Embodiment 3

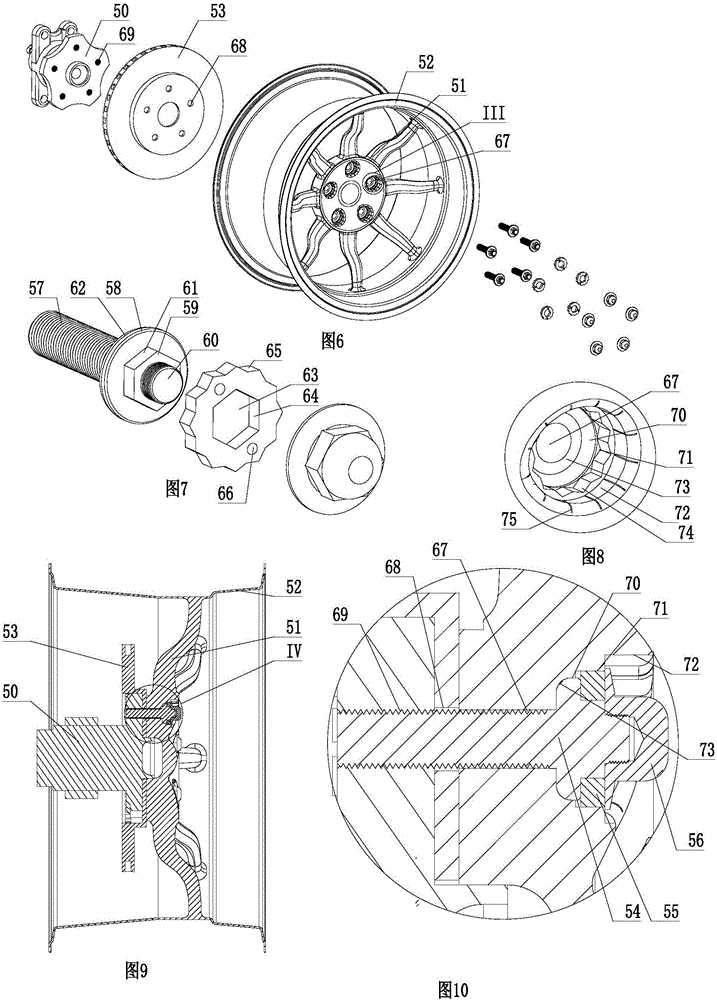

[0123] Such as Figure 11 to Figure 15 As shown, the difference from Embodiment 2 is that two removal grooves 92 communicating with the first rotation prevention hole 91 are also provided on the wall of the resisting nut accommodation hole 90 and the first rotation prevention hole 91, and the removal grooves 92 It is flush with the bottom surface of the first anti-rotation hole 91 . The anti-rotation sleeve 93 is provided with a guide inclined surface 94, and the guide inclined surface 94 faces the bottom surface of the first anti-rotation hole 91. Space 96.

[0124] The disassembly method of the wheel includes the following steps:

[0125] First, the blocking nut 97 is separated from the second external thread portion 99 of the screw rod 98;

[0126] Then use the pliers 100 to take out the anti-rotation sleeve 93 from the first anti-rotation hole 91 : the pliers 100 includes a left pliers body 101 and a right pliers body 102 that are rotatably pivoted together. The left p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com