Dismountable sealed tray circulation box

A turnover box, sealed technology, applied in packaging, transportation and packaging, rigid containers, etc., to achieve the effect of improving interchangeability, high interchangeability, and reducing scrap loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

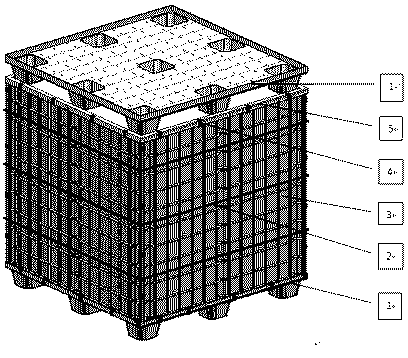

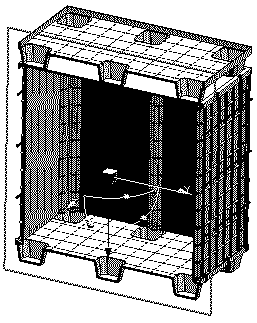

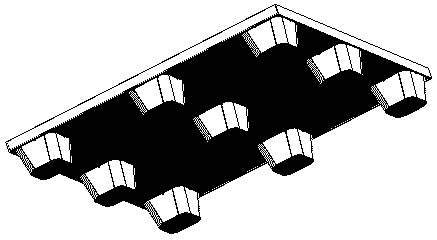

[0027] When assembling, first fill the sealing strip (8) in the sub-mouth grooves on the pallet bottom plate (1), side wall plate (3) and cover plate (5); then flatten the pallet bottom plate (1) Put it on the ground, put the four side wall panels (3) one by one into the base plate (1) and the sub-mouth grooves between the side wall panels (3) to form a turnover box; on the side wall panels (3) ) and the side wall panels (3) and the tray bottom plate (1) are fastened with the required locking buckles (4); along the box reinforcement ribs surrounded by the side wall panels (3) ( 9) Insert the required quick-insert belt (2) into the groove on the top; cover the cover (5) on the box surrounded by four side wall panels (3) through the sub-slot; Fasten the required locking buckle (4) on the joint edge of the side wall panel (3) and the cover panel (5). At this moment, a complete detachable pallet turnover box that can be sealed and airtight has been assembled.

[0028] When disas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com