Profile forming method, profile forming program, and printing system

A technology for profiles and printing media, applied in printing devices, printing, electrical recording technology using charge graphics, etc. The effect of present, proper color reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0043] Now, a first embodiment of the present invention will be described with reference to the drawings.

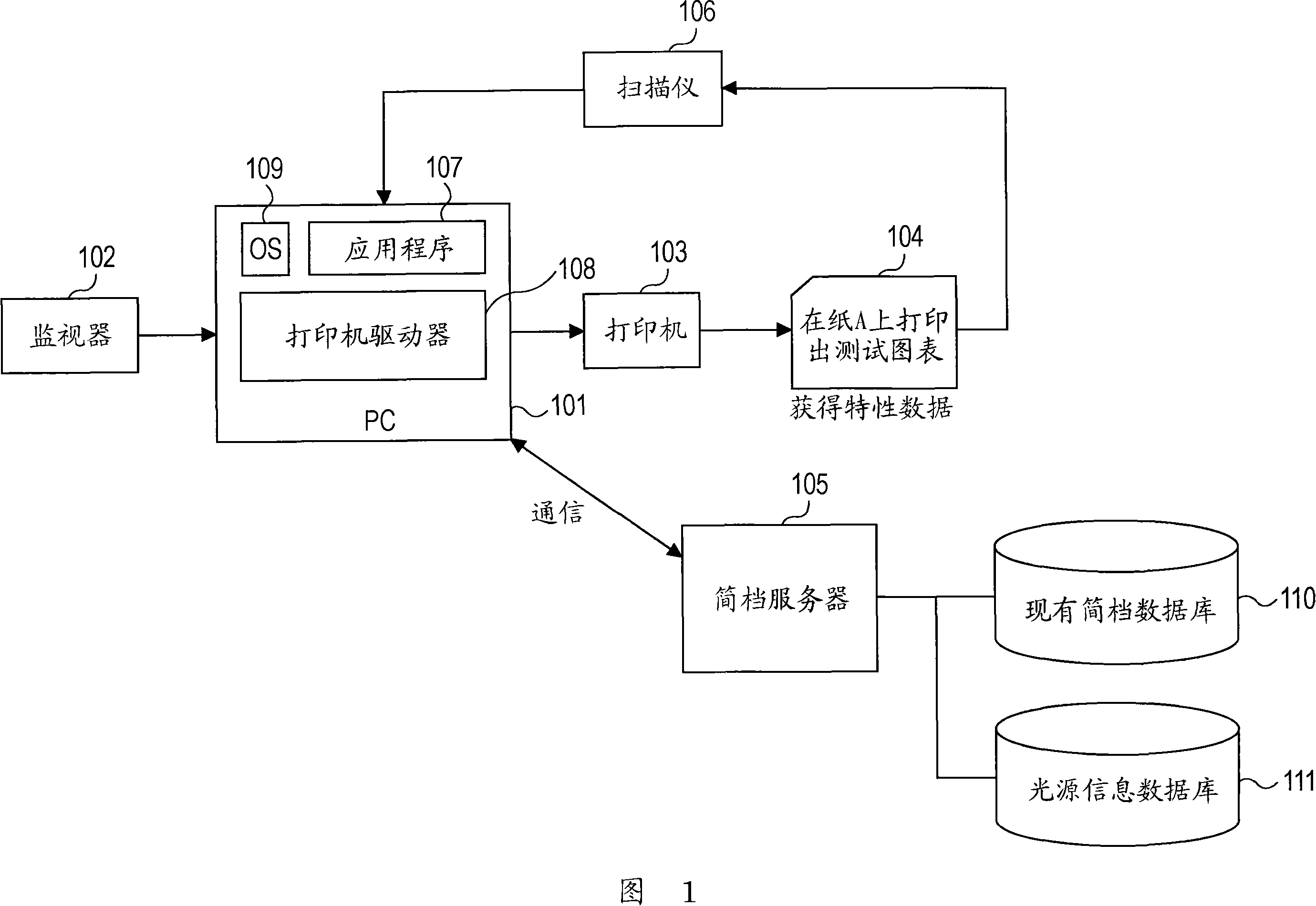

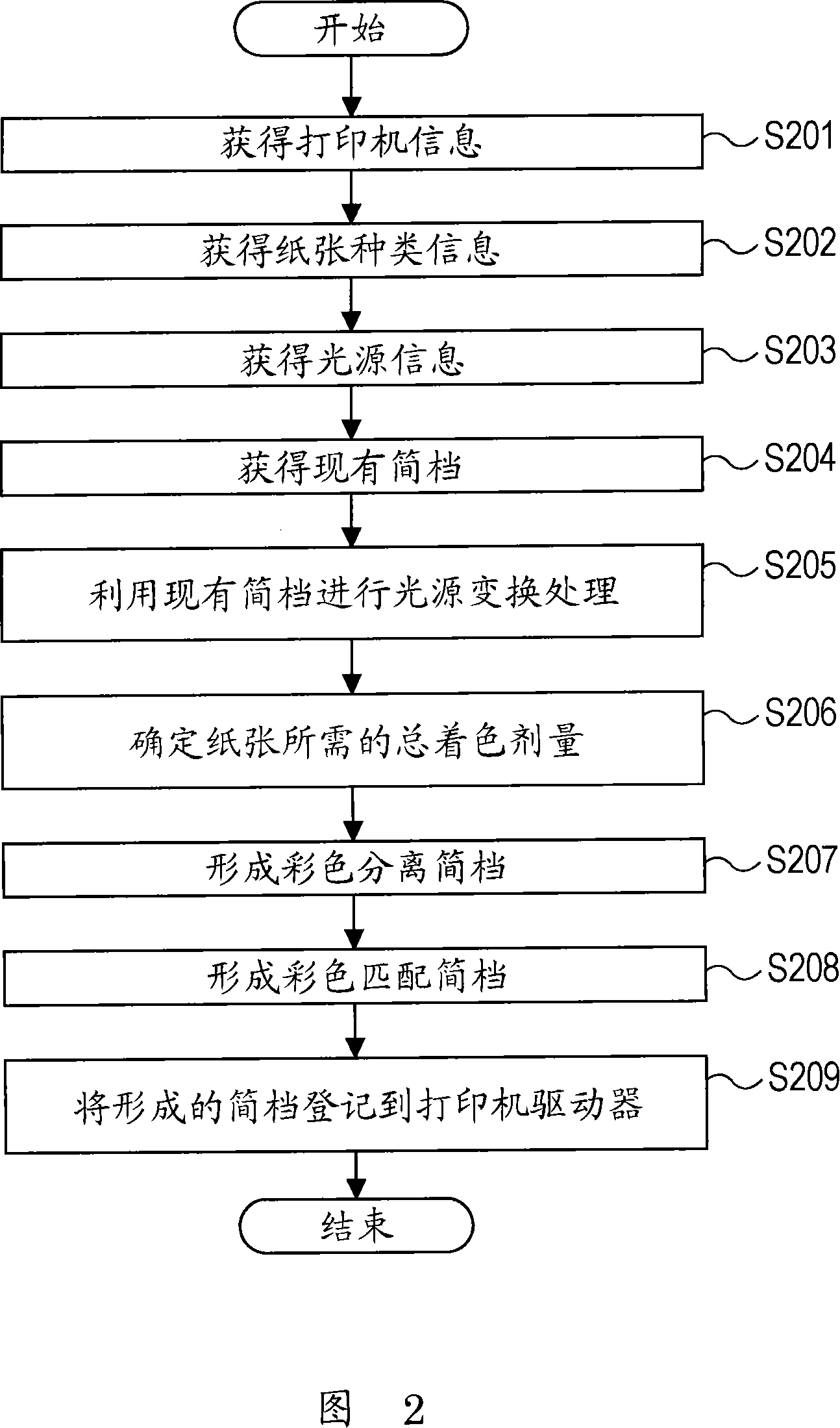

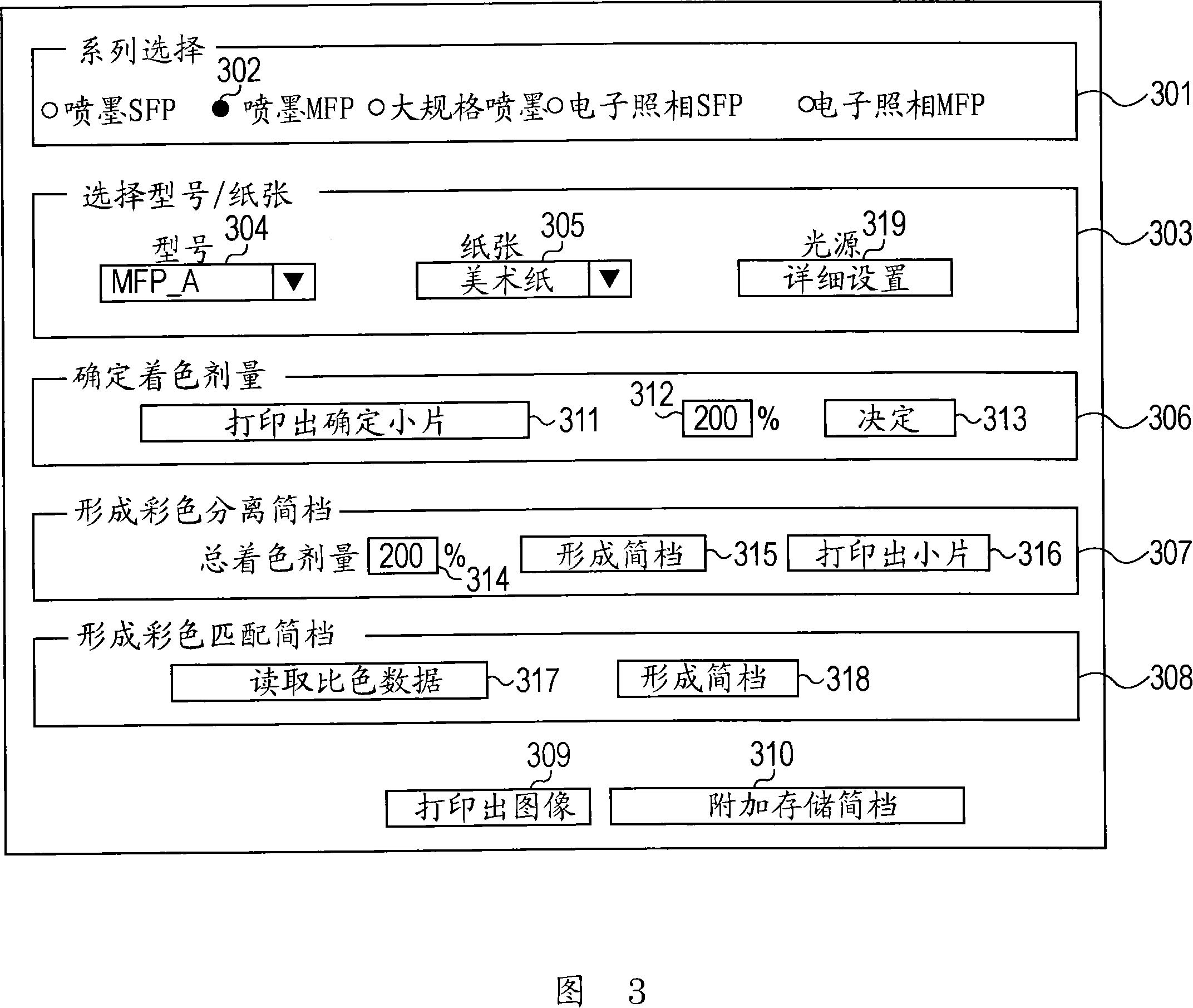

[0044]1 and 4 are block diagrams of an image printing system according to a first embodiment of the present invention. The image printing system includes: a PC 101 for controlling; an image display device 102 such as a monitor for displaying images; and an image forming device 103 such as a printer for printing images. Reference numeral 104 denotes a test chart printed by the printer 103 using paper on which the user wishes to print an image. The test chart 104 is, for example, a printout of printing image data in 9 levels (729 colors in total) in each of RGB. Here, it is required that the image data can provide color reproduction characteristics under the printing environment (including printer and paper) where the user wishes to print the image. The image printing system further includes: a profile server 105 for sending a printer profile to a printer driver through ...

no. 2 example

[0074] When professional photographers and painting and calligraphy artists utilize large-scale printers (represented by 805 in FIG. 8 ) to produce works, if they repeatedly print dozens of printed products according to the trial and error method, the cost of paper will be significantly increased, and the printing time will be prolonged. Utilizing the second embodiment of the present invention, by first using a small-format printer (indicated by 803 in FIG. 8 ) to generate a reduced work, and then profiling the large-format printer, the same color reproduction as the small-format printer is guaranteed. steps to avoid this problem.

[0075] Next, a second embodiment will be described with reference to FIG. 8 .

[0076] Fig. 8 is a block diagram of an image printing system according to a second embodiment of the present invention. This image printing system includes a PC 801 for control, which is the same as the PC used in the image printing system according to the first embodi...

no. 3 example

[0079] The third embodiment of the present invention can easily form a profile that can provide the color reproduction characteristics of the paper that the user usually uses when another paper is used. Next, a third embodiment will be described with reference to FIG. 9 .

[0080]Fig. 9 is a block diagram of an image printing system according to a third embodiment of the present invention. This image printing system includes a PC 901 for control, which is the same as the PC used in the image printing system according to the first embodiment. In addition, the image printing system further includes: an image display device 902, such as a monitor, for displaying images; and an image printing device 903, for example, a printer, for printing images. Reference numerals 904 and 905 denote test charts printed by the printer 903 in cooperation with different types (A and B) of paper required by the user to finally print images. The test charts used in this third embodiment are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com