Evaporation container

A technology for evaporating container and water vapor, applied in the direction of container, pervaporation, flexible container, etc., can solve the problems of rupture, unsealed film bag, heavy weight of water to be purified, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

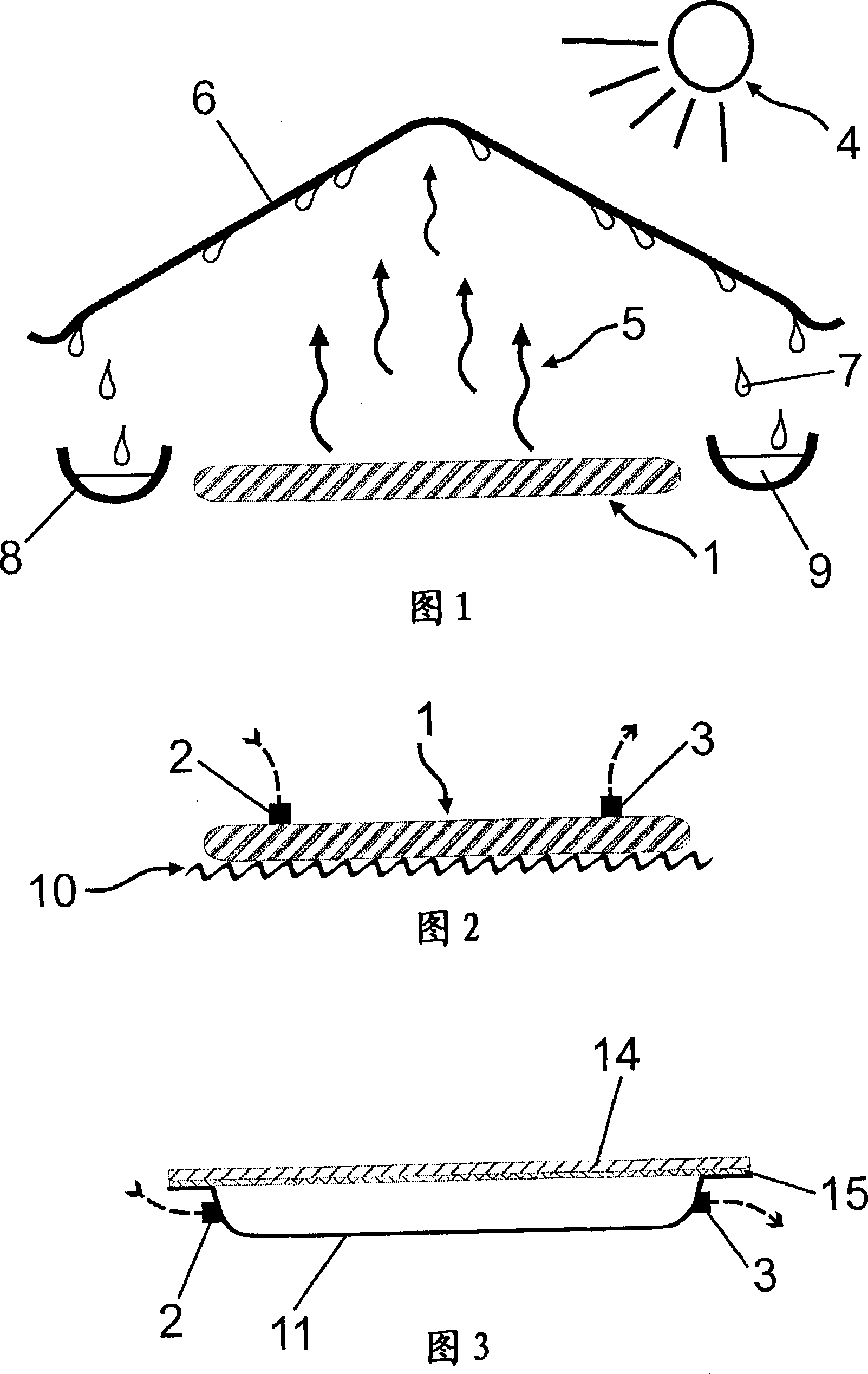

[0032] According to FIG. 1 , the evaporation container 1 according to the invention containing the water to be purified is arranged under a roof 6 which can be penetrated by the rays of the sun 4 . At least a part of the evaporation vessel 1 is formed by a laminate (not shown) comprising a watertight, non-porous and water vapor permeable membrane. The film in contact with the water to be purified releases water vapor 5 due to the permeability of water vapor, and then the water vapor 5 condenses on the top cover 6 and drops into the tank 8 in the form of water droplets 7, where it gathers into The resulting purified water 9 .

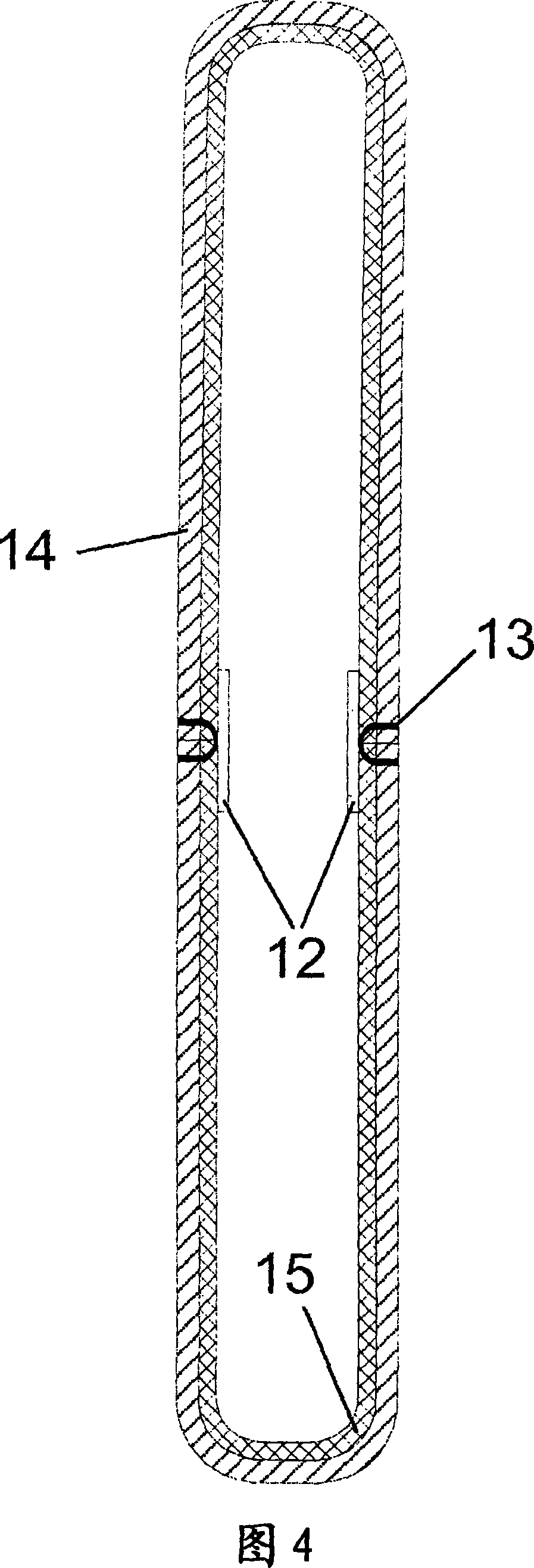

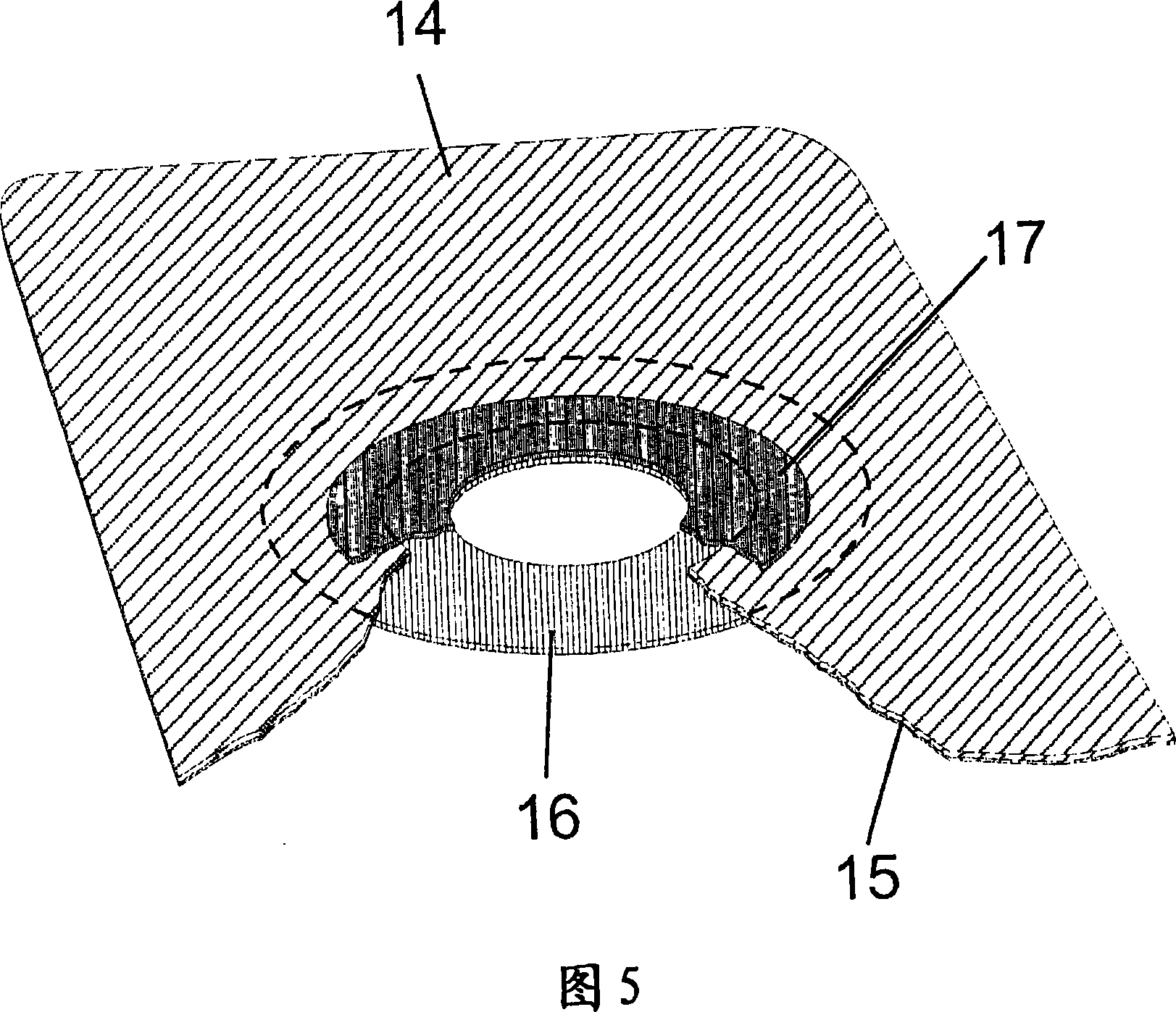

[0033] As shown in Figure 2, the evaporation vessel 1 can be equipped with an input 2 and an output 3 for the water to be purified. If the bottom of the evaporation vessel 1 also has a laminate with a watertight, non-porous and water vapor permeable film, it can be placed directly on the ground to moisten the ground, as for example in WO 01 / 10192 as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com