Temperature control system of acrylic softening furnace for preparing child bathtub

A temperature control system and temperature controller technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of bottom deformation, lack of deformation control mechanism, inability to strengthen the support structure and strengthen the bathtub support, etc., to reduce the probability of deformation , Good support effect, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

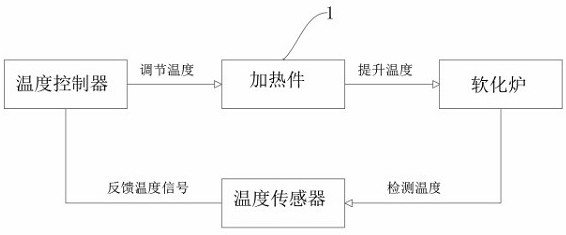

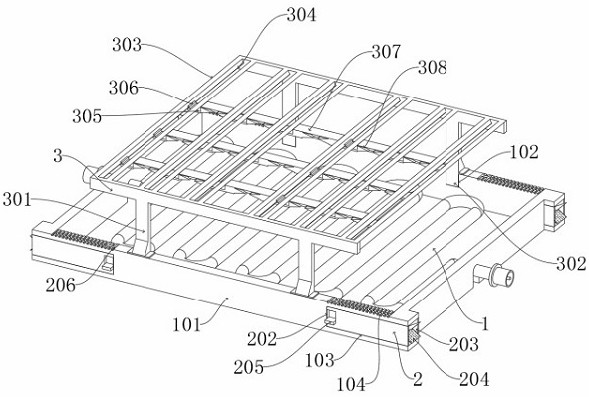

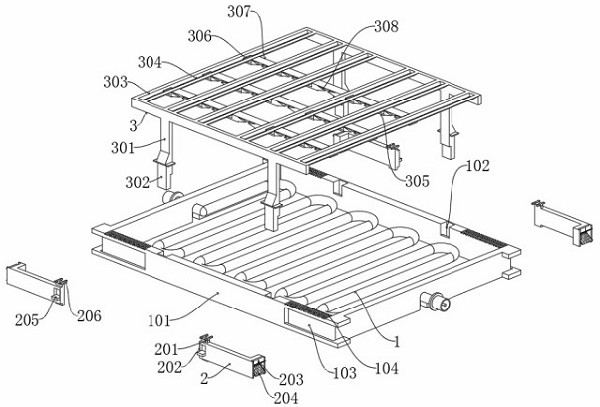

[0028] as attached figure 1 to attach Figure 10 As shown: the present invention provides a temperature control system for an acrylic softening furnace for preparing children's bathtubs, including a heating element 1; the heating element 1 is installed inside the softening furnace, and the heating element 1 is electrically connected to the temperature controller. A temperature sensor, the temperature sensor is electrically connected to the temperature controller; the moving part 2, the moving part 2 is an L-shaped structure, and the moving part 2 is installed inside the adjustment tank 103, so that the moving part 2 can be drawn and pulled at will, and then adjusted conveniently Fixed position, moving part 2 comprises: contact plate 204, and contact plate 204 is a V-shaped plate structure, is to be able to deform, and then enlarges contact area, and the outer end of contact plate 204 is a wedge-shaped structure, and contact plate 204 is a spring plate material, so that when t...

Embodiment 2

[0033] When the bathtub is slightly softened, the installation part 3 can be controlled to be removed, so that the insertion rod 302 can be pulled out from the inside of the slot 102, so that the fixing part 101 can support the softening of the bathtub.

Embodiment 3

[0035] When the bathtub needs to be softened heavily, multiple auxiliary plates 305 can be controlled to be installed together, so that the fixing block 306 can be embedded in the inside of the through groove 304, and then the multiple top blocks 307 can be stressed together to avoid serious deformation of the bathtub softening.

[0036] When in use: when the device needs to be used, the connection between the fixing part 101 and the heating part 1 can be controlled by manpower, so that the fixing part 101 can be placed on the top of the heating part 1, and then the pulling plate 205 is pulled upward by manpower to make the clamping block 206 It can be disengaged from the inside of the fixing groove 104, so that the moving part 2 can release the limit, and then push the moving part 2 to displace, so that the moving part 2 can squeeze the contact plate 204, so that the contact plate 204 can be squeezed and deformed, and then enlarged The contact area with the inner wall of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com