Multifunctional drought-resistant seeding and fertilizing plough

A multi-functional, fertilizing plow technology, applied in the direction of fertilizers and sowing equipment, plows, planting methods, etc., can solve the problems of unstable sowing plows, difficult entry into the ground, increased labor intensity, etc. The effect of promoting drought resistance, moisture conservation and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

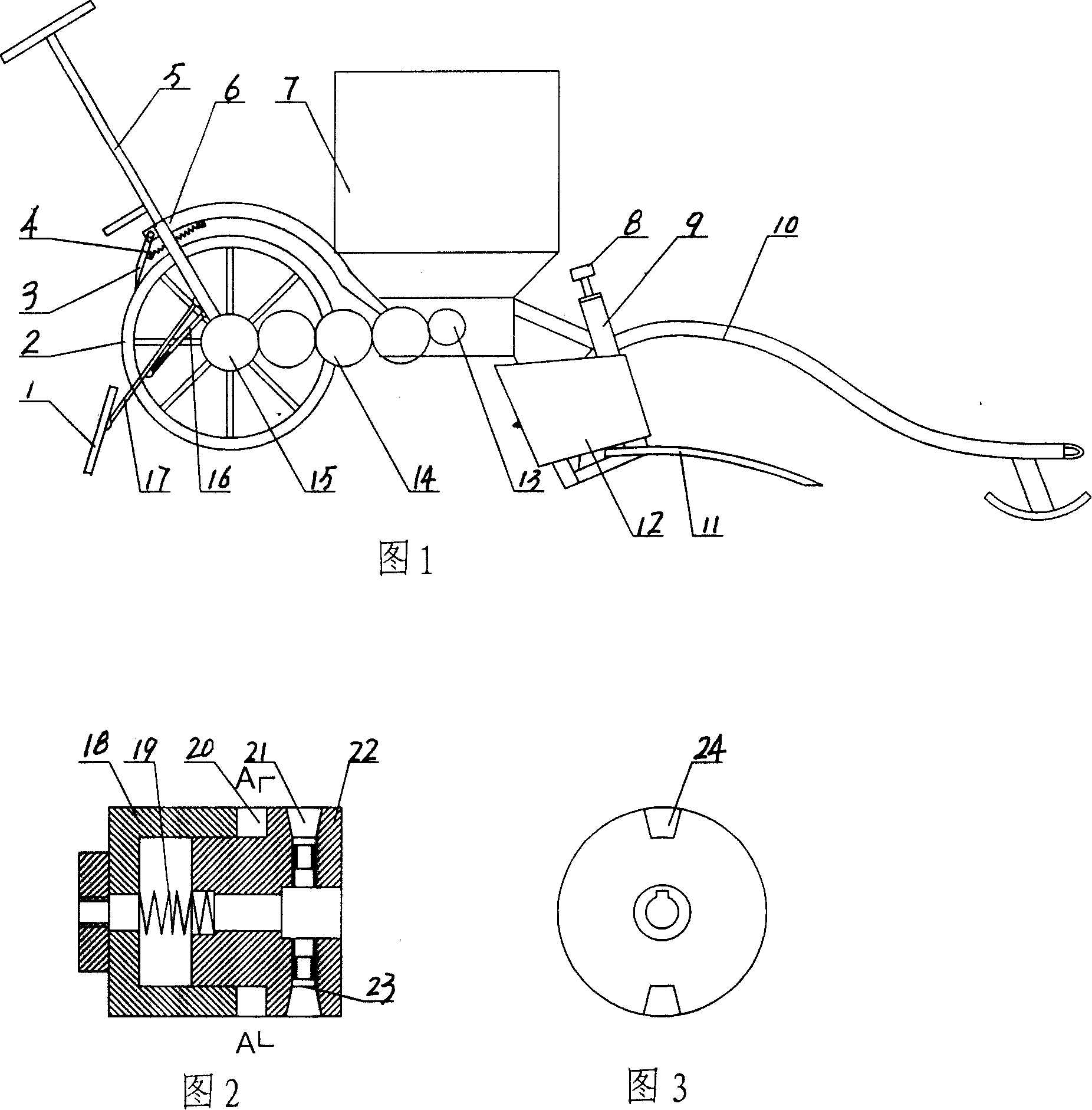

[0018] As shown in Figures 1-3, a multifunctional drought-resistant sowing and fertilizing plow includes a frame 6, a ditch opener, a seeding and fertilizing applicator, a ground wheel 2 and a handrail 5, and the ground wheel is installed below the said frame. The ground wheel shaft of the wheel is connected to the transmission mechanism, and the transmission mechanism is a gear transmission mechanism. Three transmission gears 14 are installed between the main gear and the discharge gear, and the said ditch opener is fixed below the said sowing and fertilizing device, plowshares 11 are installed on the ditch opener, and the soil divider is installed behind the said ditch opener. Plate 12, the plow shaft 10 is movably installed at the junction of the sowing and fertilizing device and the ditch opener, the two sides of the ground wheels at the bottom of the frame are respectively connected to the pull rods 17, and the other ends of the two pull rods are connected to the soil cove...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap