Clothing without sewing thread and method for manufacturing plaster type clothes without sewing thread and application thereof

A non-sewing and pasting technology, which is applied in the field of non-sewing thread clothes and pasted non-sewing thread clothing, can solve the problems of affecting the appearance of clothes, affecting the wearing of clothes, and disconnection of sewing threads, so as to improve economic benefits, Good anti-cracking effect, wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

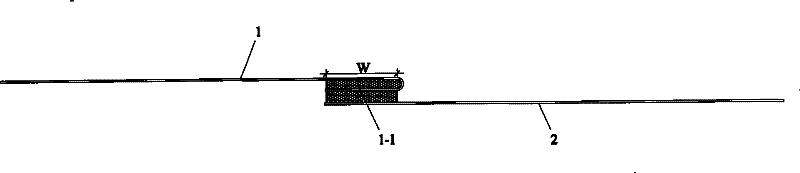

[0027] figure 1 One form of operation of the invention is shown by figure 1 It can be seen that the pasting method for making clothes without sewing threads comprises the following steps: (1) applying hot melt adhesive to the chemical fiber cloth 1 joint edge 1-1 within a width W of 7mm; (2) bending the cloth joint edge 1-1 1. Form the bone position, and the width of the bone position is also about 7 mm; (3) use a hot press to heat and press the bone position; (4) Use a hot press to heat another piece of chemical fiber cloth 2 and the bone of chemical fiber cloth 1, so that the two pieces of chemical fiber cloth 1 and 2 are glued together to achieve no sewing thread Clothing effect.

Embodiment 2

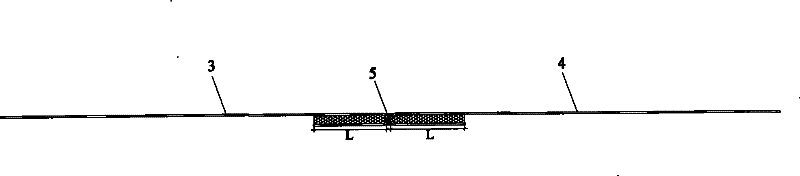

[0029] figure 2 Another embodiment of the present invention is shown by figure 2 It can be seen that the method for making garments without sewing thread of this adhesive type comprises the following steps: (1) on the joint edges of the two pieces of cloth 3 and 4 to be joined (one of which is cotton cloth 3; the other is nylon cloth 4) Apply silica gel within the width L of 3.5mm; (2) respectively bend the joint edges of the two pieces of fabric 3 and 4 to form bone positions on the two pieces of fabric 3 and 4 respectively; (3) heat and press them with a hot press The bones of the two fabrics 3 and 4; (4) The bones of the two fabrics 3 and 4 are relatively close to each other, and the total width of the bones of the two fabrics 3 and 4 is about 7 mm; Put the silica gel 5 on the butt joint of the bone, and use the laser to irradiate the melt glue, so that the bone of the two pieces of cloth 3 and 4 are connected together, realizing the effect of making clothes without sewi...

Embodiment 3

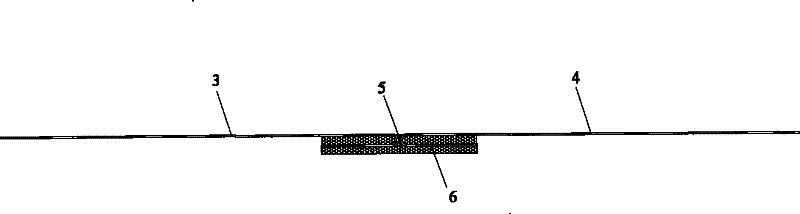

[0031] image 3 Another embodiment of the present invention is shown, consisting of image 3 It can be seen that this embodiment is the same as Example 2 except for the following features: after laser melting, apply silica gel 6 on the bone surface of the two pieces of cloth, and then heat and press them with a hot press to make the glue and the bone closely adhere together, so as to strengthen the connection, making the connection between the two bones more firm and reliable

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com