Multi-ratio automatic transmission with independent rate of engagement and/or disengagement control of friction elements

A technology of transmission device and friction element, applied in the field of multi-speed automatic transmission device, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] introduction

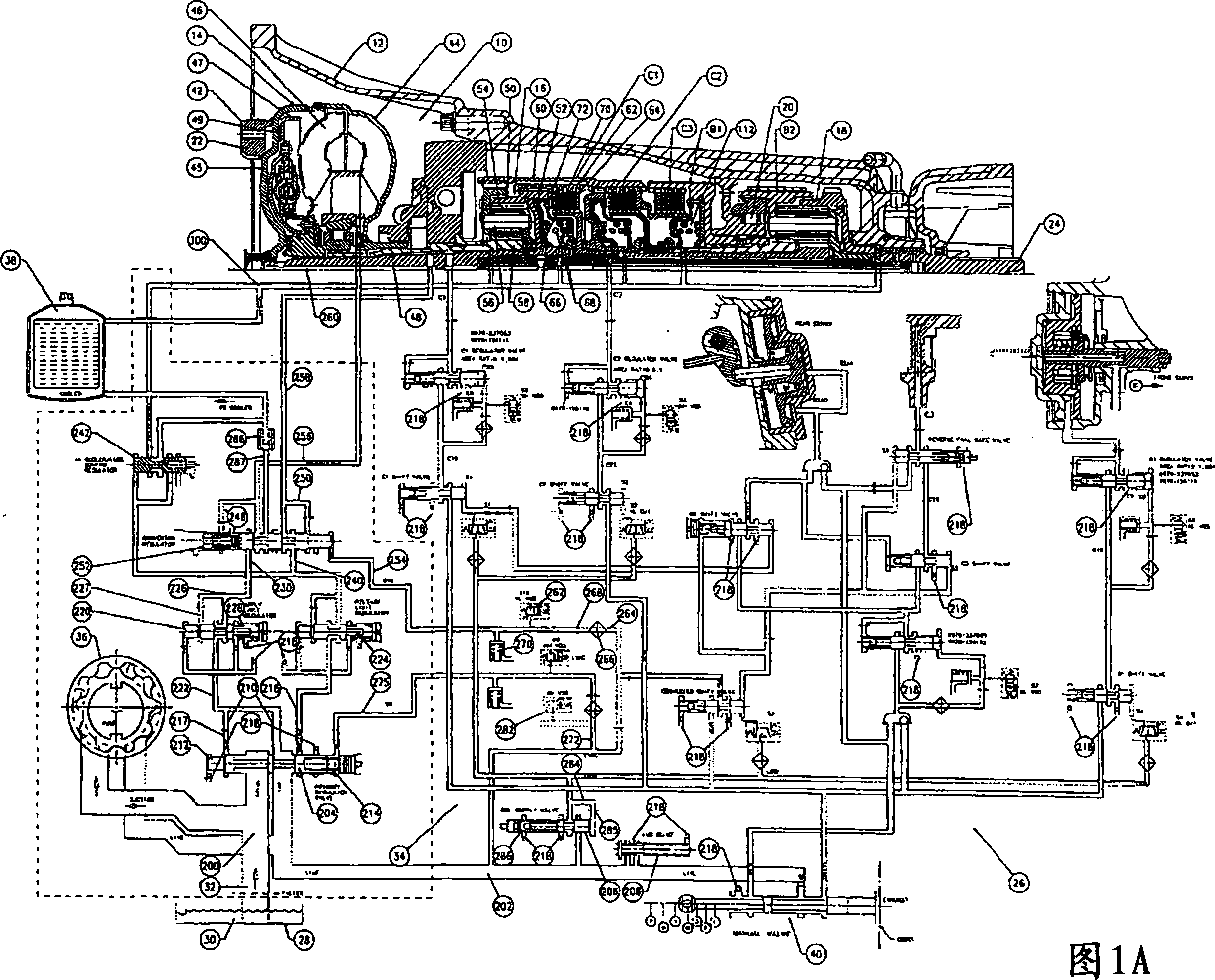

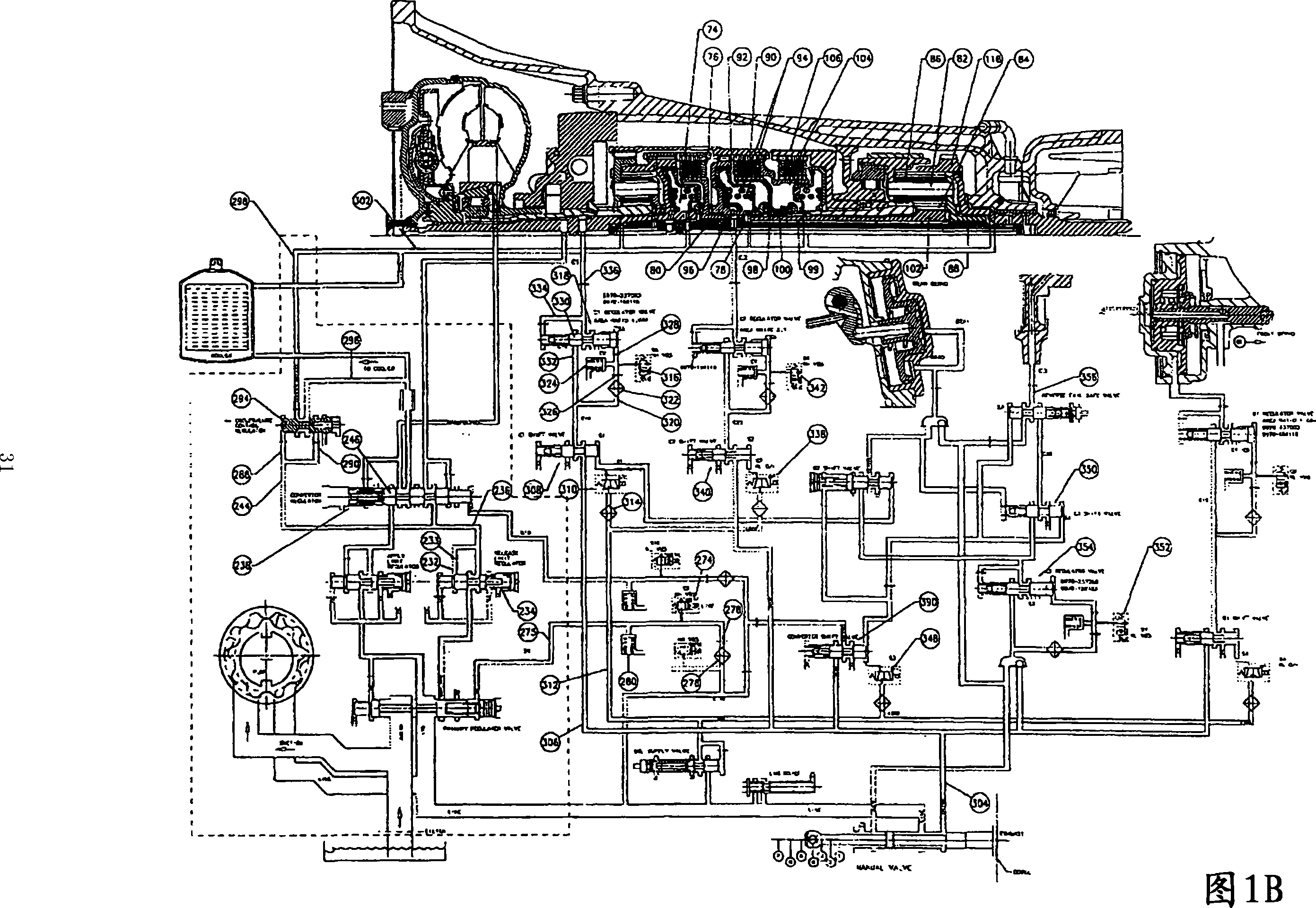

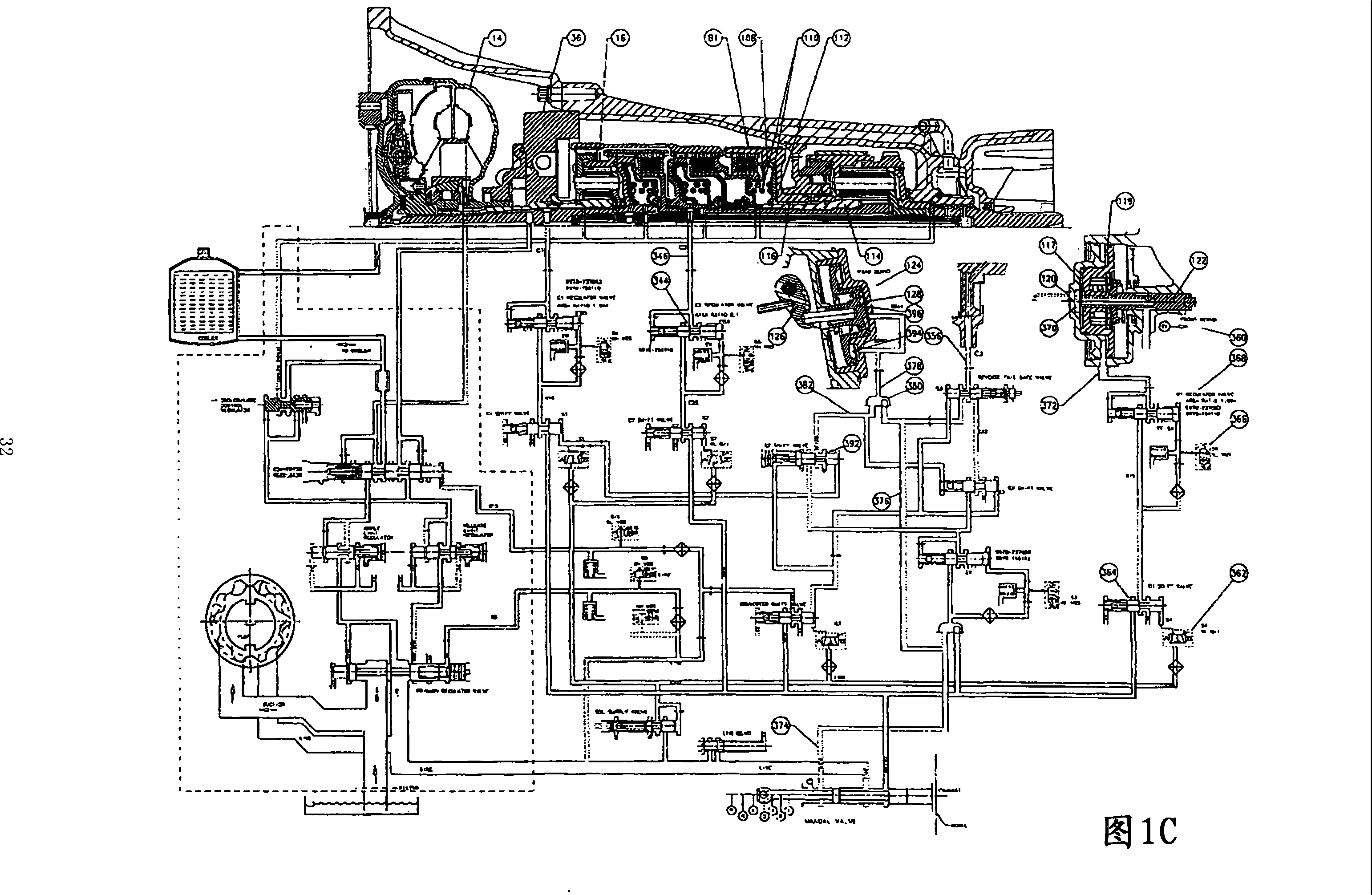

[0049] Referring to Figures 1A, 1B, 1C and 2A, an automatic transmission 10, especially for a rear-wheel drive vehicle, has a bell-shaped housing 12 in which a torque converter 14, three friction clutches C1, C2 are housed. and C3 , two braking bands B1 and B2 , a first simple planetary gear set 16 , a second Ravigneux-type planetary gear set 18 and a one-way clutch 20 . Since each of clutches C1 , C2 and C3 and brake bands B1 and B2 are friction elements (ie, used to selectively hold one portion relative to another by friction), transmission 10 has a total of five friction elements. The transmission 10 utilizes these mechanical components to transmit power at different ratios from the input 22 of the transmission 10 to the output 24 of the transmission 10 . The exemplary transmission shown in the drawings provides six forward gear ratios for forward propulsion of the vehicle and a reverse gear ratio and a neutral state for reverse propulsion of the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com