Working machinery

A technology for working machines and machine rooms, which is applied to the field of working machines for roofs, and can solve the problems of smaller openings for inspection, reduced workability, and wasted time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

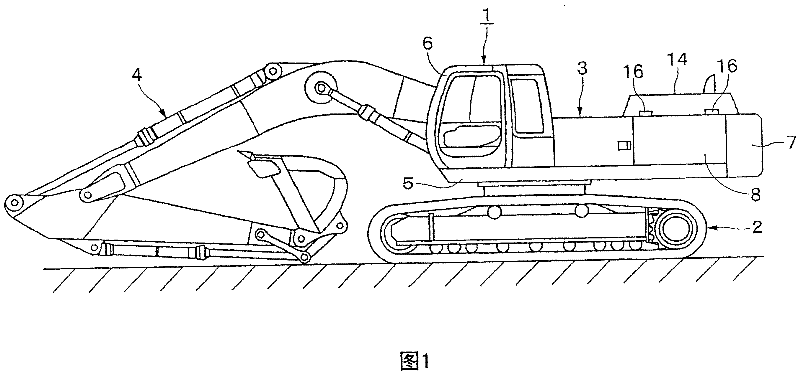

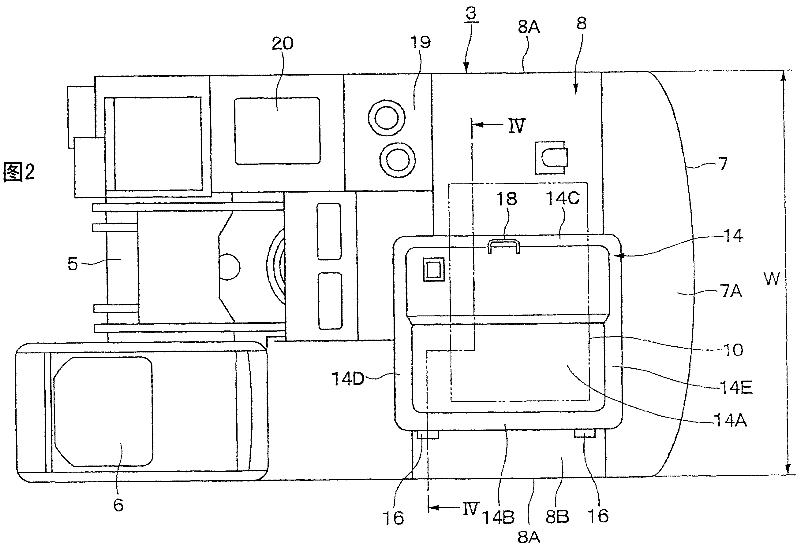

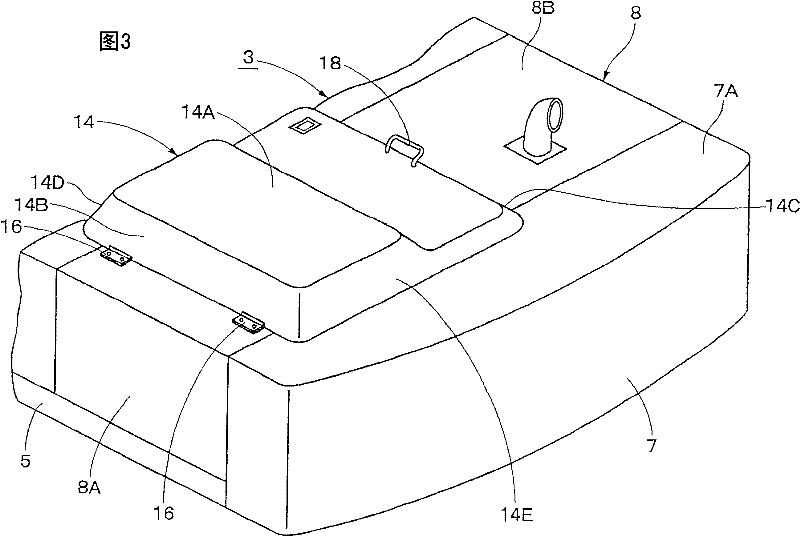

[0033] Hereinafter, a detailed description will be given with reference to the drawings and taking a case where the work machine of the embodiment of the present invention is applied to a hydraulic excavator as an example.

[0034] Here, Figure 1 to Figure 11 This shows the first embodiment of the present invention. In the figure, the mark 1 is a hydraulic excavator as a working machine. The general structure of the hydraulic excavator 1 includes: figure 1 As shown, the crawler-type lower body 2 that can travel automatically; the upper rotating body 3 rotatably loaded on the lower body 2; and the upper part is movably installed up and down for excavation work such as sand and soil The working device 4 at the front of the rotating body 3.

[0035] In this case, the upper rotating body 3 of the hydraulic excavator 1 and the lower traveling body 2 constitute the vehicle body of the work machine. The upper rotating body 3 is composed of a rotating frame 5, a cab 6, a counterweight 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com