Adhesive tape sweeping structure

A tape cleaning and belt technology, which is applied in the direction of cleaning devices, transportation and packaging, and conveyor objects, can solve the problems of up and down vibration, that is, up and down movement, increase the rotating workload of the transmission roller, and reduce the effective transmission volume, etc., to achieve Increase practicality, enhance the scope of application, and reduce the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

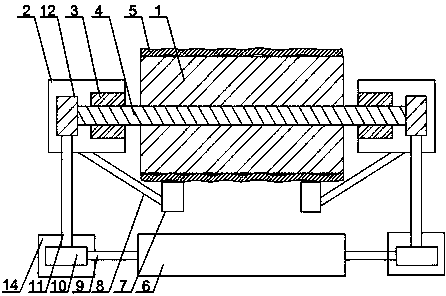

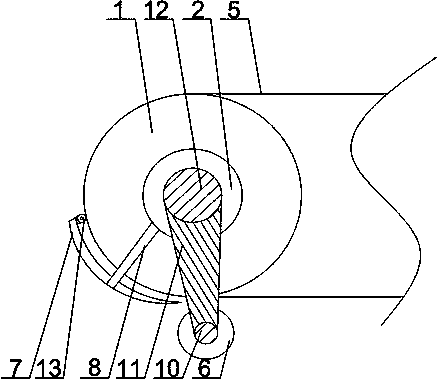

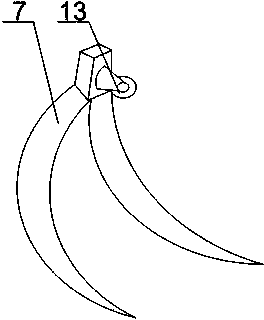

[0025] Such as Figure 1 to Figure 4As shown, the adhesive tape cleaning structure of the present invention includes a transmission drum 1 and a support cylinder 2, a bearing seat 3 is installed in the support cylinder 2, and a rotating shaft 4 of the transmission cylinder 1 runs through one end of the support cylinder 2 and is rotatably arranged in the bearing housing 3 , the rotating shaft 4 is provided with a knife loading shaft 6 parallel to the rotating shaft 4, the knife loading shaft 6 is installed at the position before the belt 5 turns, and a plurality of blades 15 are arranged on the knife loading shaft 9 A plurality of said blades 15 are hinged with the cutter shaft 9 and the annular array is distributed on the outer wall of the cutter shaft 9, the cutter shaft 9 is placed in the fixed cylinder 6 and the two ends of the cutter shaft 9 protrude from both ends of the fixed cylinder 6 At the end, there is an opening corresponding to the blade 15 on the fixed cylinder 6...

Embodiment 2

[0027] Such as figure 1 As shown, this embodiment is based on Embodiment 1. The blade adjustment structure includes a screw 17 and an arc-shaped plate 16. The arc-shaped plate 16 is connected to the inner side of the blade 15, and an internal thread hole 18 is opened on the arc-shaped plate 16. , the screw rod 17 is rotatably arranged at the end of the fixed cylinder 6, and the screw rod 17 passes through the inner threaded hole 18 and is threadedly engaged with the arc-shaped plate 16. Blade 15 of the present invention adopts arc blade, and according to the thickness size of the residual material on belt 5, under the condition of not moving cutter shaft 9, the opening angle of blade 15 is increased, to reduce the gap between blade 15 and residual material. Adjust the distance between the screw rods 17 so that the arc-shaped plate 16 moves quickly through the screw rod 17 and the internal threaded hole 18, and then drives the blade 15 to move to realize the adjustment of the b...

Embodiment 3

[0029] Such as Figure 1 to Figure 3 As shown, in this embodiment, on the basis of Embodiment 1, a large gear 12 is installed at both ends of the rotating shaft 4, and a protection cylinder 14 is installed at both ends of the fixed cylinder 6, and a small gear 10 is arranged in the protection cylinder 14. , the end of the cutter shaft 9 runs through one side of the protective tube 14 and is connected with the pinion 10 , the two ends of the connecting rod 11 are equipped with racks, and the bull gear 12 cooperates with the pinion 10 through the connecting rod 11 . The rotating shaft 4 rotates, and under the cooperation of the large gear 12, the small gear 10 and the connecting rod 11, the rotating shaft 4 will drive the knife loading shaft 6 and the transmission roller 1 to rotate synchronously, so as to ensure that the knife loading shaft 6 is in contact with the residual material and cleaned up .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com