Novel four-link hinge assembly

A hinge assembly, four-bar hinge technology, used in hinges with pins, door/window accessories, folding boards, etc., can solve the problem that the outer spring is easy to fall off and hurt people, the hinge cup affects the service life, and the impact is not solved. problems, to achieve the effect of no need to refuel and maintain, prolong the service life, and have a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

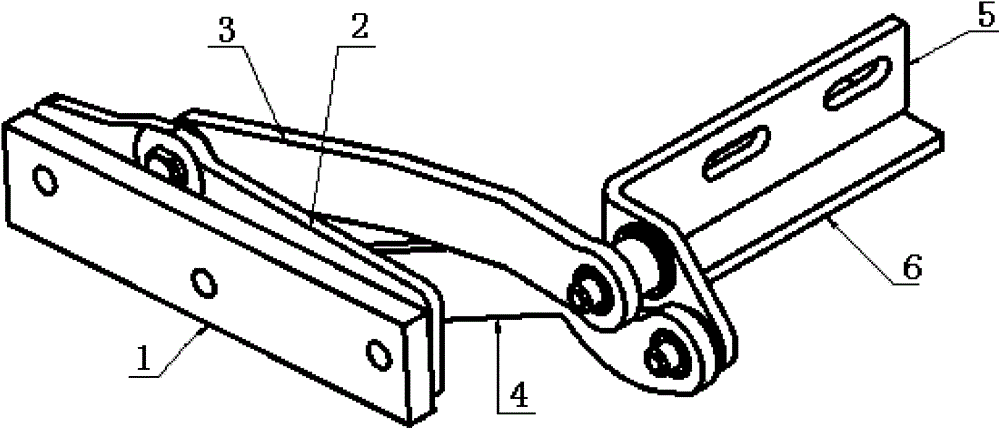

[0017] Such as figure 1 As shown, a new four-bar linkage hinge assembly is used to connect the vehicle body and the door. The hinge assembly includes a connecting plate 1, a four-bar hinge moving plate 2, a first lining bar 3, a second lining bar 4, and a hinge fixing plate 5. , Fixed plate partition 6. The connecting plate 1 is welded on the side wall column of the vehicle body. The four-bar hinge moving plate 2 is connected with the connecting plate 1. One end of the first lining bar 3 and the second lining bar 4 is movably connected with the four-bar hinge moving plate 2 . The other ends of the first lining bar 3 and the second lining bar 4 are movably connected with the hinge fixed plate 5 . The hinge fixed plate 5 is connected with the fixed plate partition 6 . The hinge fixed plate 5 is fixedly connected with the car door by bolts.

[0018] One end of the first lining bar 3 and the second lining bar 4 is connected with the four-bar hinge moving plate 2 by rivets. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com