Ball joint

A ball joint and ball handle technology, applied in the field of ball joints, can solve the problems of no installation, poor sealing performance of dust-proof lip, easy exposure to sewage environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

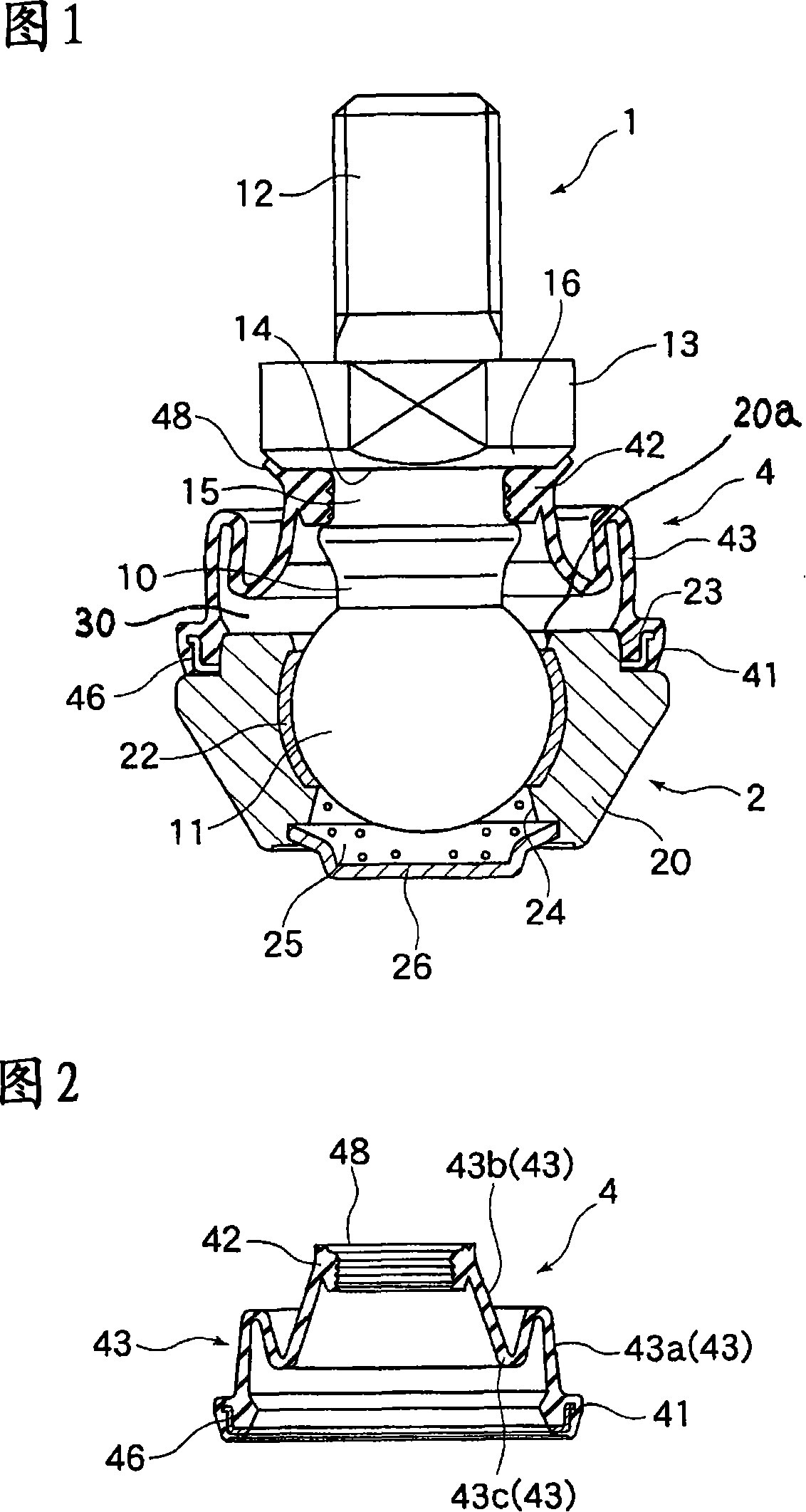

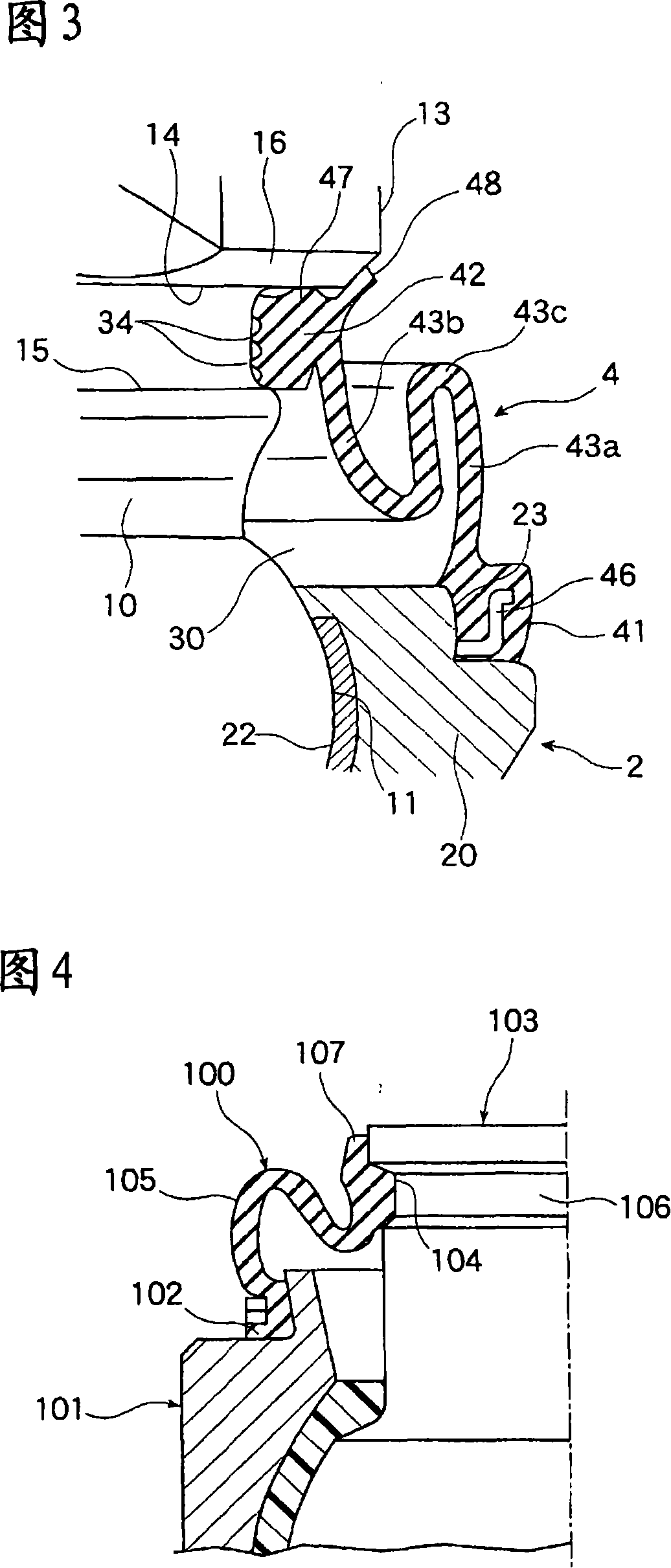

[0017] Next, the ball joint of the present invention will be described in detail with reference to the drawings.

[0018] FIG. 1 is a diagram showing an embodiment of a ball joint to which the present invention is applied. In this figure, reference numeral 1 is a handle body, reference numeral 2 is a holding seat that is freely connected with the handle body 1 to swing and rotate freely, and reference numeral 4 is a handle installed to cover the handle. The sheath sealing body of the connecting part of the body 1 and the holder 2.

[0019] The knob body 1 is a member in which a ball portion 11 is formed at the tip of a substantially cylindrical shaft portion 10 . The ball portion 11 is formed by welding a high-spherical bearing steel ball to the shaft portion 10 in order to achieve smooth sliding contact with the holder 2 . In addition, a male screw portion 12 is formed at the end of the shaft portion 10 opposite to the ball portion 11, and a flange portion 13 is provided ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com