Method for determining error of the oil ejecting execution element ejection quantity

A technology of control device and injection quantity, applied in the direction of fuel injection control, electrical control, engine control, etc., can solve problems such as the influence of exhaust gas quality engine noise, and achieve the effect of preventing unwanted disappearance, reliable and accurate compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

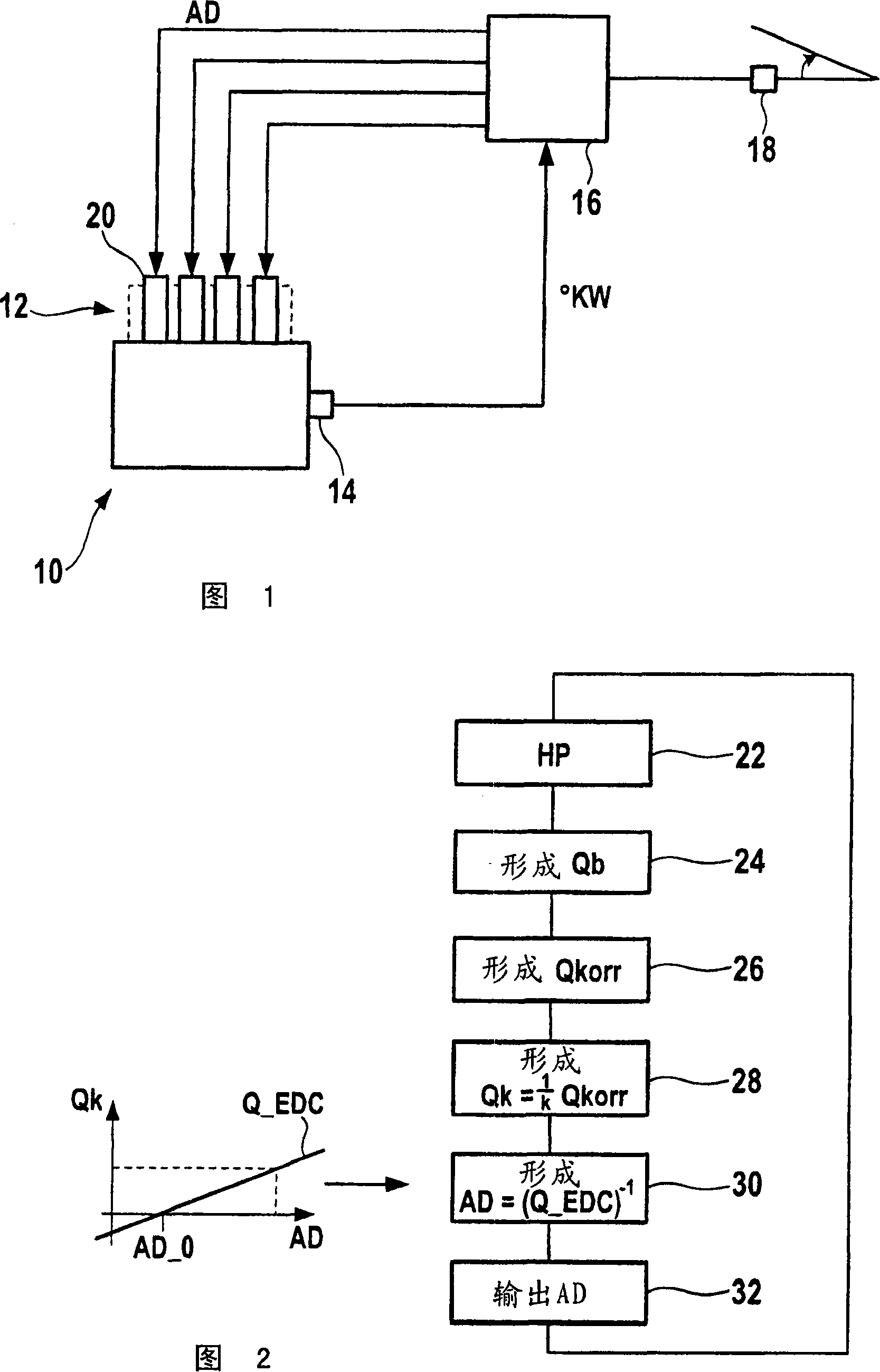

[0019] FIG. 1 shows in detail an internal combustion engine 10 with a fuel injection system 12 , an angle sensor 14 , a control unit 16 and a driver desire sensor 18 . Fuel injection system 12 has at least one fuel injection actuator 20 . Injection actuator 20 is designed as an injector with which fuel is individually metered into a combustion chamber of internal combustion engine 10 . The internal combustion engine 10 is preferably a diesel engine, but the invention is not limited to diesel engines, but gasoline engines and Wankel engines can also be used.

[0020] Driver desire sensor 18 is used to detect the torque request of internal combustion engine 10 . If the internal combustion engine 10 is used as a motor for a road vehicle, the torque request is given by the driver. As an alternative or in addition, however, the torque request can also be predetermined by a function of the vehicle which is carried out in the control unit 16 or in another control unit of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com