Lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and separator technology, applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve problems such as leakage of lithium-ion battery separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

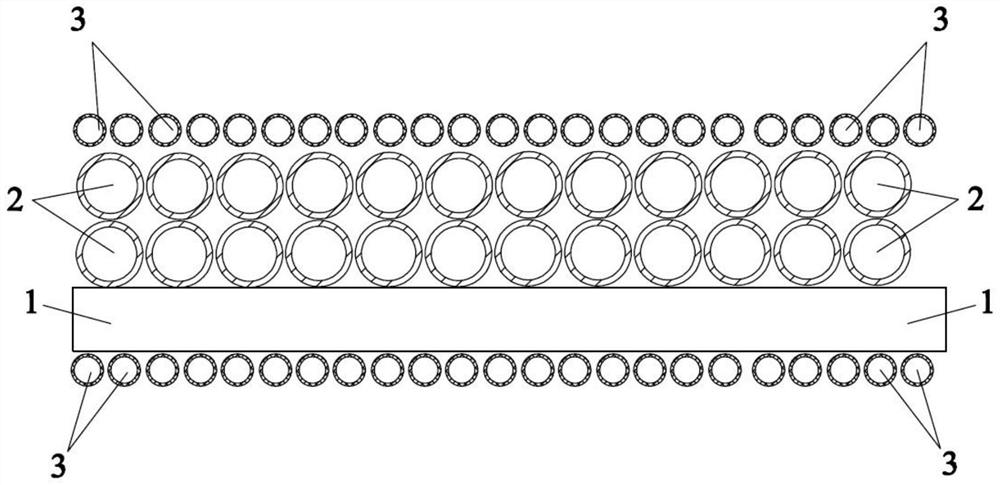

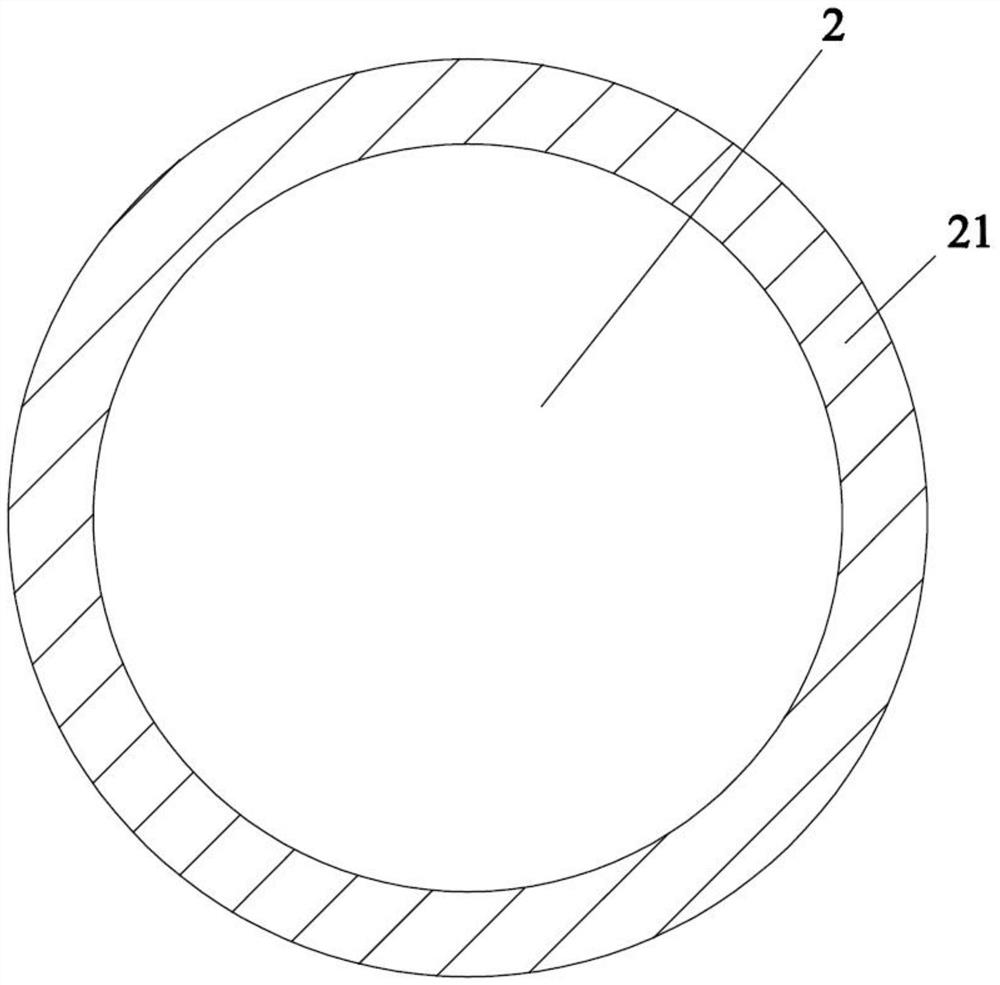

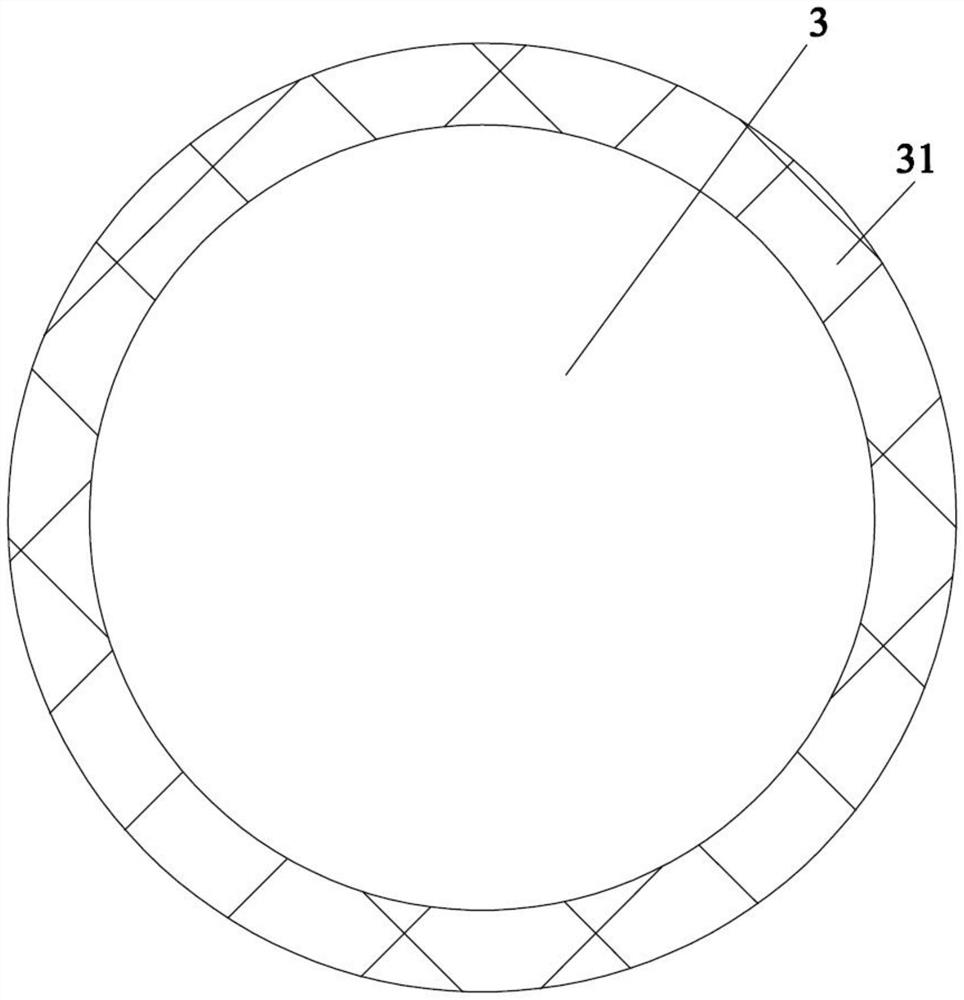

[0034] Lithium-ion battery separator, comprising base material 1 and the coating that is arranged on the surface of base material 1, coating comprises ceramic coating 2, polymer coating 3; Multilayer ceramic coating 2 is arranged on one side of base material 1, Two layers of polymer coatings 3 are respectively provided on the surface of the ceramic coating 2 and the other side of the substrate 1 , the ceramic coating 2 is provided with a first dyeing agent 21 , and the polymer coating 3 is provided with a second dyeing agent 31 .

[0035]Since the conventional isolation film is coated with single-layer or multi-layer ceramics, polymer slurry or ceramic-polymer mixed slurry on the base film substrate, the color of the ceramic coating 2 and the polymer slurry is close to that of the base film itself, all of which are milky white , due to human factors or equipment failure, it is difficult to observe with the naked eye when there is leakage in the coating process, and when the lea...

Embodiment approach 2

[0041] The difference from Embodiment 1 is that the coating in this embodiment is a ceramic polymer hybrid coating, and the ceramic polymer hybrid coating is arranged on at least one side of the substrate 1, and the ceramic polymer hybrid coating is provided with a third coloring agent, The third dyeing agent is coated on the surface of the ceramic polymer mixed coating, and the ceramic polymer mixed coating includes SiO2, Al2O3, CaO, TiO2, MgO, ZnO, SnO2, ZrO2, AlOOH, MgOH2, BaSO4, PVDF, PMMA At least one, the ceramic polymer hybrid coating has a thickness of 0.2um-10um. Specifically, at least one of SiO2, Al2O3, CaO, TiO2, MgO, ZnO, SnO2, ZrO2, AlOOH, MgOH2, BaSO4, PVDF, and PMMA is used as the main material of the ceramic-polymer hybrid coating, at 10-40 ° C, Under the condition of ambient humidity of 30-75%, add binder, CMC, dyeing agent, etc. in a certain order, and mix at high speed with a double planetary mixer and grind with a pin-type sand mill to prepare a viscosity ...

Embodiment approach 3

[0044] The difference from the first embodiment is that the ceramic coating 2, the polymer coating 3 and the ceramic-polymer hybrid coating of this embodiment are all provided with an adhesive, and the adhesive includes polyacrylate, polyacrylonitrile, poly At least one of vinyl alcohol, silicone, epoxy resin, polyurethane, ceramic coating 2, polymer coating 3 and ceramic polymer hybrid coating are all provided with a thickener, the thickener includes methyl cellulose , carboxymethyl cellulose, hydroxyethyl cellulose, hydroxypropyl methyl cellulose at least one, the first dyeing agent 21, the second dyeing agent 31 and the third dyeing agent all include chromophoric group and auxiliary Chromophores, including nitro, azo, and vinyl groups, and auxochrome groups are acidic groups and basic groups.

[0045] It should be noted that the thickener includes at least one of methylcellulose, carboxymethylcellulose, hydroxyethylcellulose, and hydroxypropylmethylcellulose, and the relati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com