Patents

Literature

33results about How to "To achieve the purpose of inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

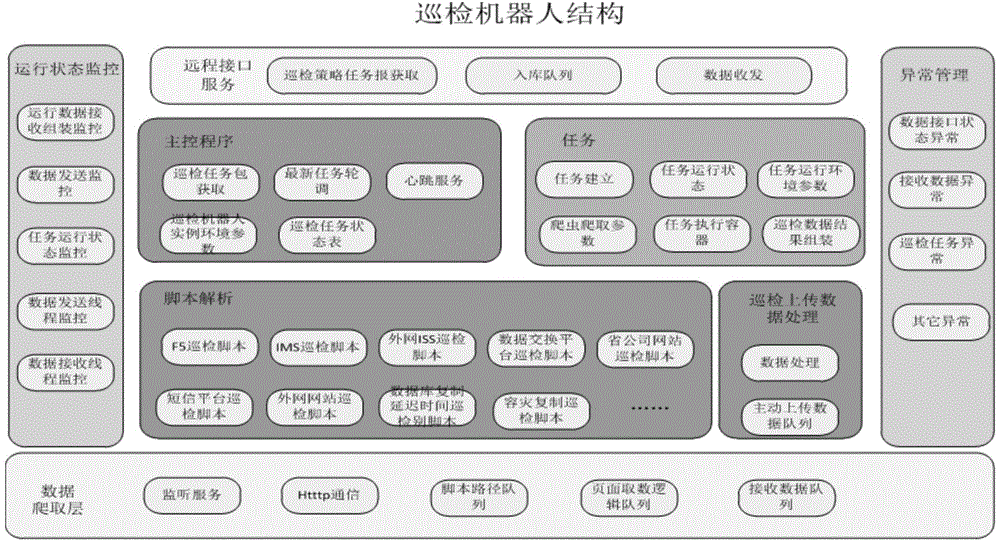

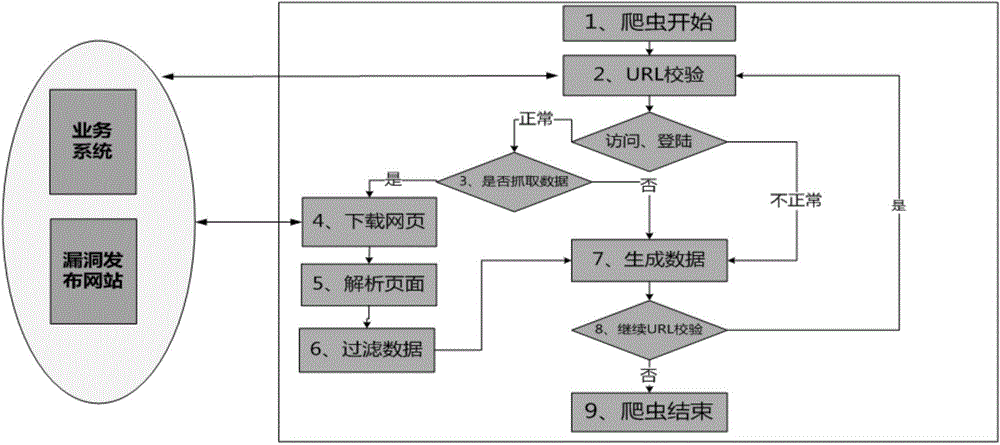

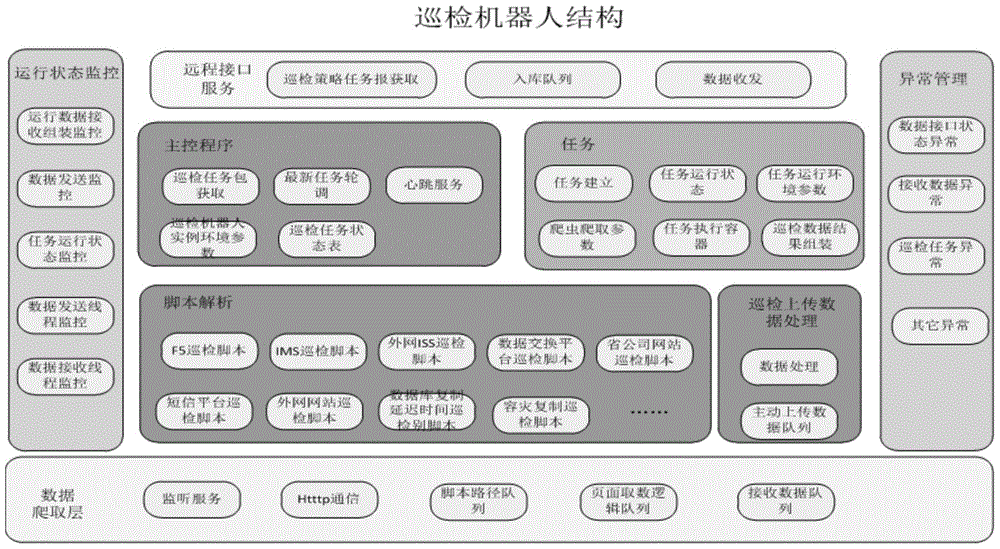

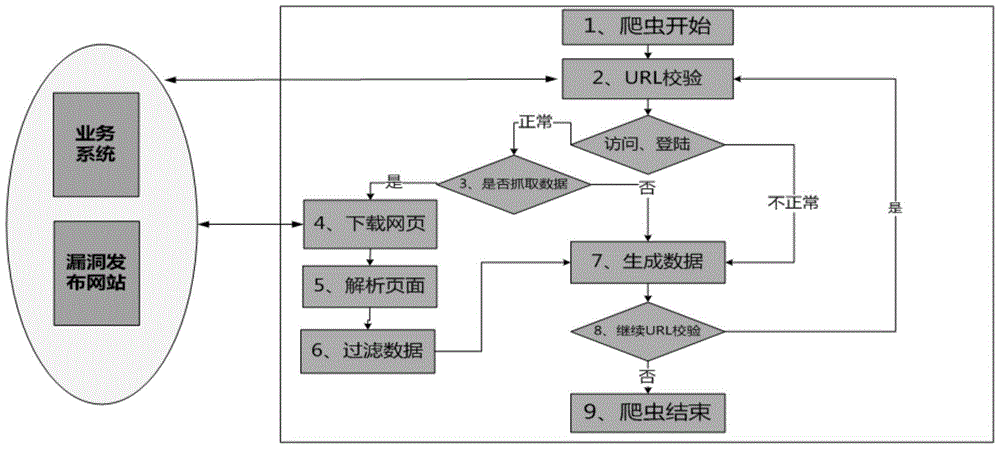

Power dispatching automation polling robot and method based on reptile technology

ActiveCN104539053AQuick and accurate discoveryFast and accurate positioningCircuit arrangementsTransmissionPower dispatchInformation system

The invention discloses a power dispatching automation polling robot and method based on the reptile technology. The polling robot comprises a long-distance interface service module, a master control program module, a task module, a script analysis module, a polling uploaded data processing module, an abnormality management module and a running status monitoring module. The polling robot is based on the reptile technology, HTTP requests are simulated in an HTTP agency mode, an HttpClient and tmlParser open source assemblies are adopted for crawling links and key data of a service system needing to be monitored for the URL connection and interface analysis technologies, and automation polling on information systems is achieved. By means of the power dispatching automation polling robot and method, polling of a large number of the information systems can be carried out; the aim of polling in the script recording mode is achieved, the information system polling process is simplified, a large number of repeated manpower resources are released, and the work efficiency of dispatchers for polling the service system is improved.

Owner:STATE GRID CORP OF CHINA +3

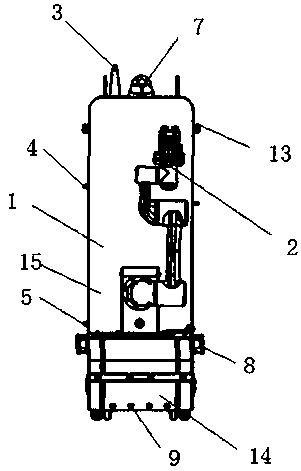

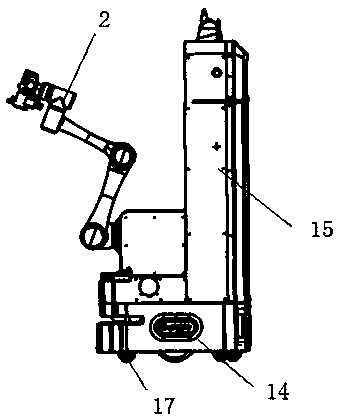

Inspection system for data center

InactiveCN108972497AAvoid electromagnetic radiation damageAvoid lostProgramme-controlled manipulatorVideo monitoringData center

The invention discloses an inspection system for a data center. The inspection system comprises a server, an intelligent terminal and an inspection robot. The intelligent terminal and the inspection robot communicate with the server through network. The intelligent terminal is used for a user to issue control commands to the server. The server generates control orders based on the received controlcommands, and sends the control orders to the inspection robot. The inspection robot enters a data center based on the received control orders, replaces manual collecting inspection data needing to be inspected of the data center, and sends the collected inspection data to the server. The server processes and stores the received inspection data and sends the inspection data to the intelligent terminal. The robot is controlled to replace manual inspecting, and defect of manual inspecting is completely overcome. A video monitoring system and sensors are not required to be mounted in a machine room, and the construction cost and the management cost of the machine room are greatly lowered.

Owner:桑瑞思医疗科技有限公司

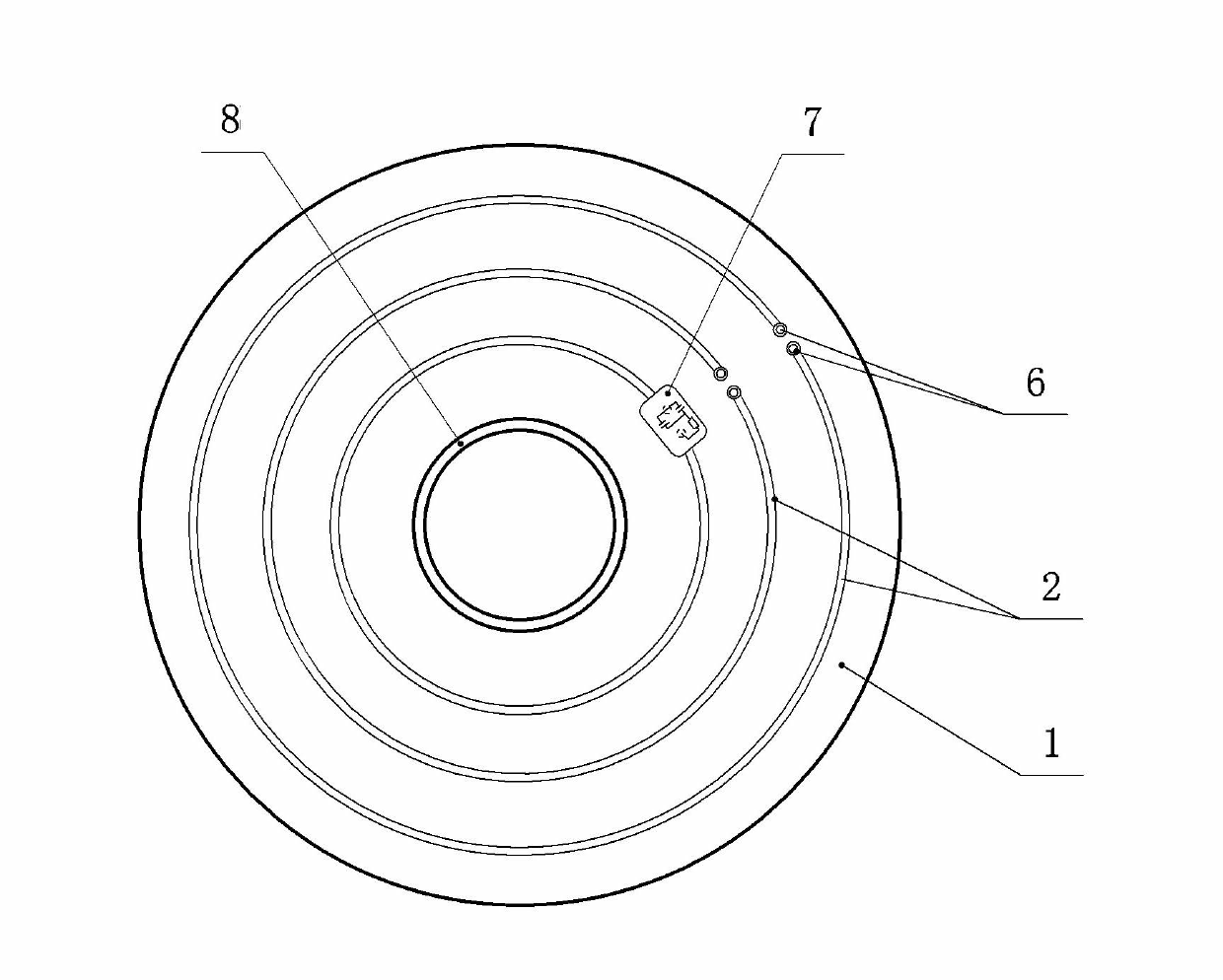

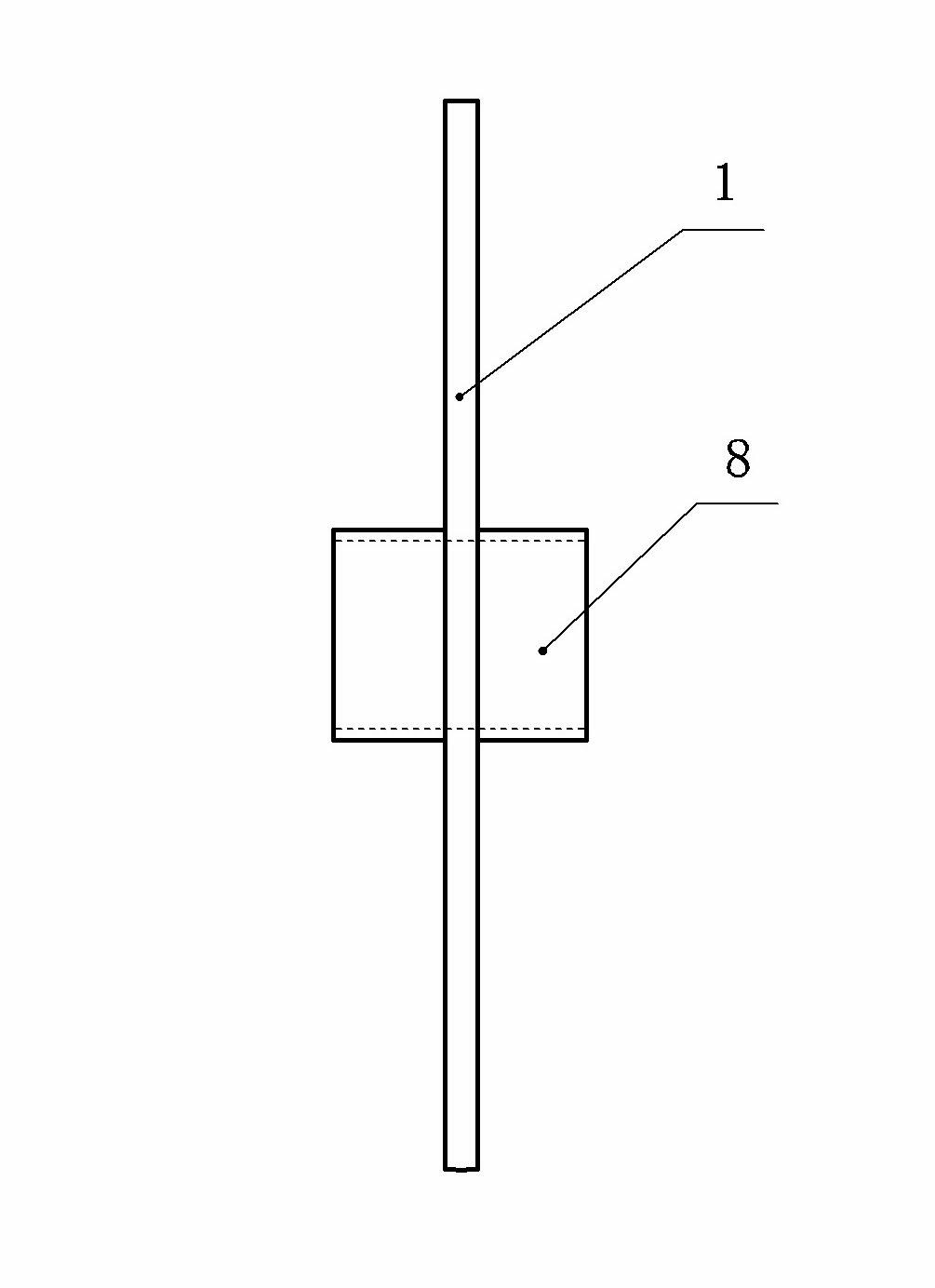

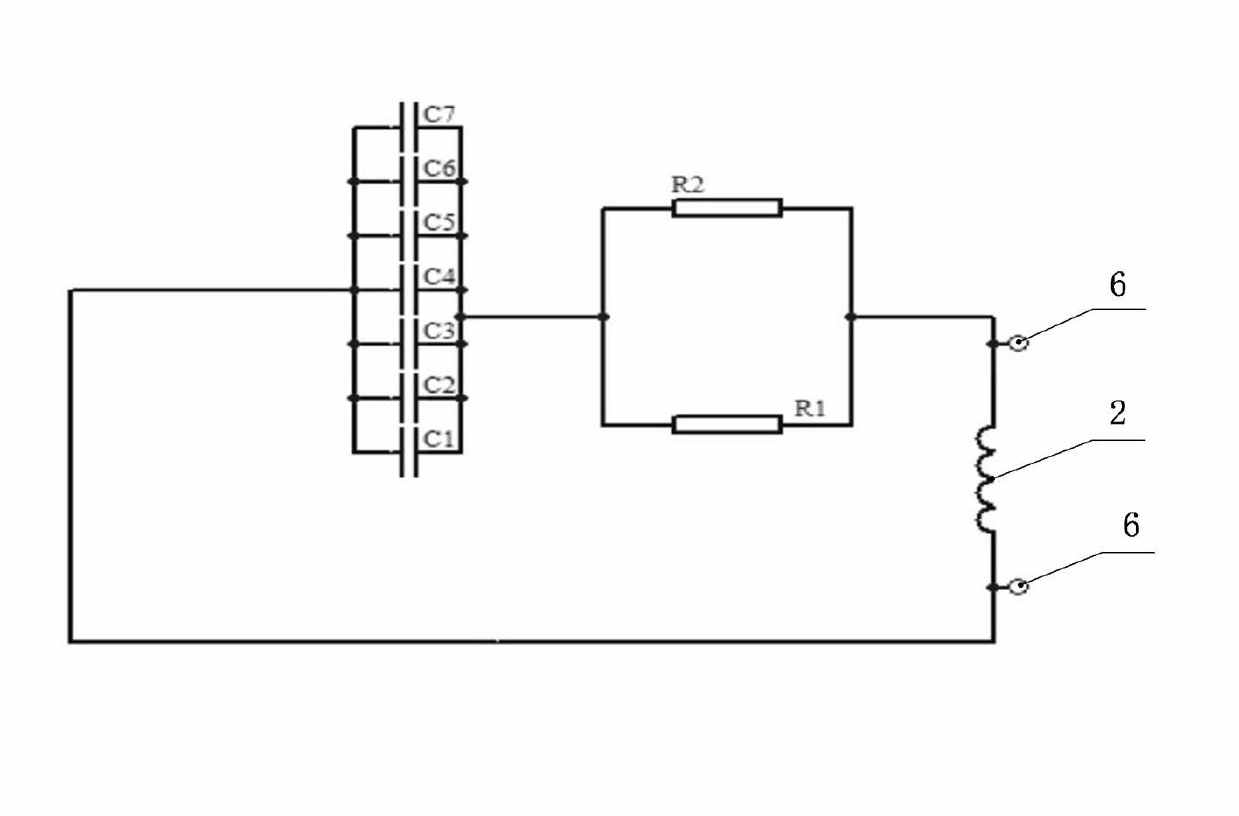

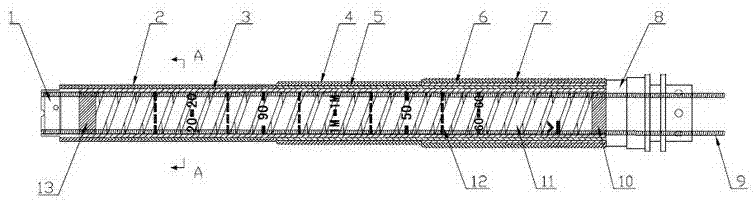

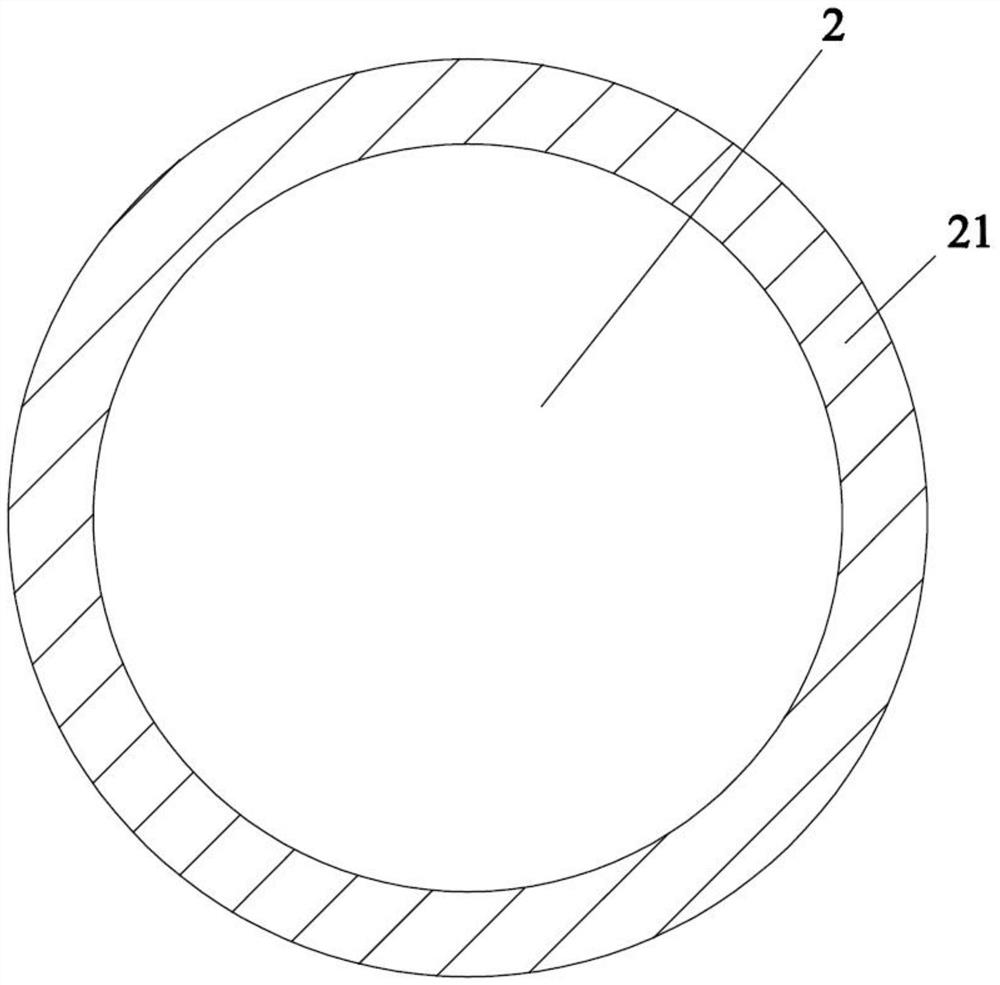

Response testing device for electromagnetic wave resistivity logging-while-drilling tool

InactiveCN102606148AImprove the efficiency of outdoor scaleReduce workloadGeological measurementsBorehole/well accessoriesResistance capacitanceComputational physics

The invention relates to a testing device for testing response of an electromagnetic wave resistivity logging-while-drilling tool in a room, in particular to a response testing device for an electromagnetic wave resistivity logging-while-drilling tool, which comprises a disk insulating support. The diameter of a central hole of the disk insulating support is matched with that of the electromagnetic wave resistivity logging-while-drilling tool, at least one open circular metal ring (2) is arranged on a support disk surface of the disk insulating support and gradually distributed outwards around the support disk surface of the disk insulating support, and a quick joint (6) is led out of an end of a notch of each circular metal ring and additionally provided with n resistance-capacitance modules (7) in a matched manner, wherein n is a natural number. The testing device is simple in structure and convenient in use, and can guarantee outdoor scale test for the electromagnetic wave resistivity logging-while-drilling tool to a certain degree.

Owner:THE 22ND RES INST OF CHINA ELECTRONICS TECH GROUP CORP

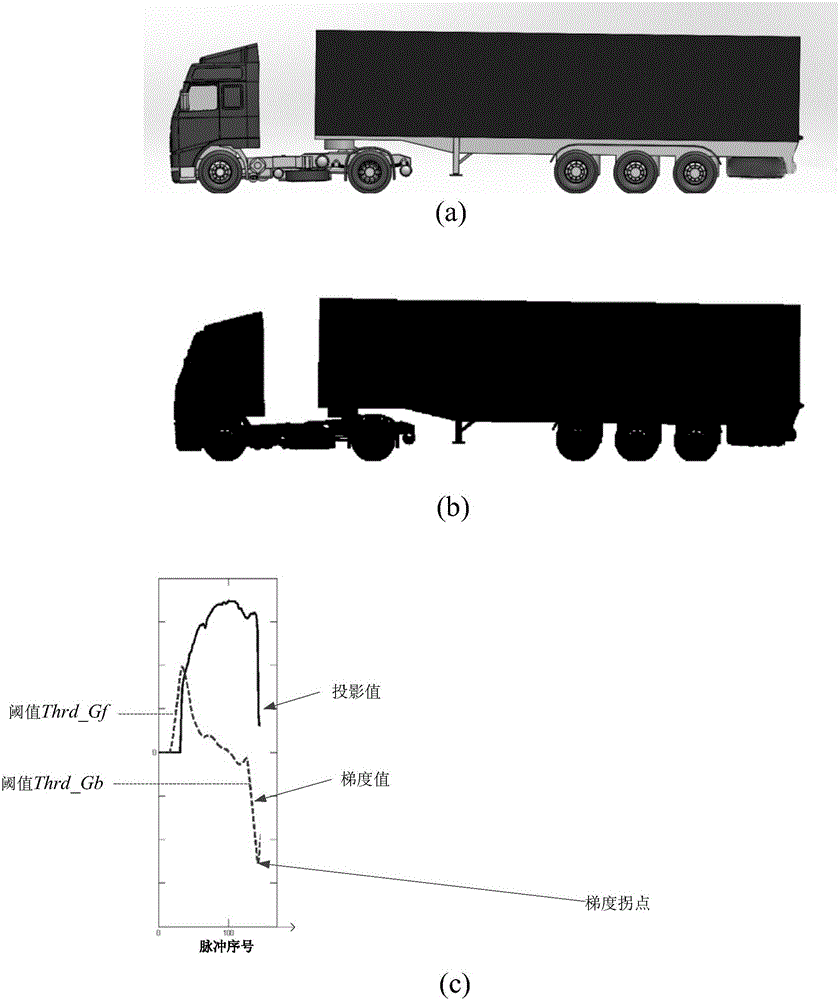

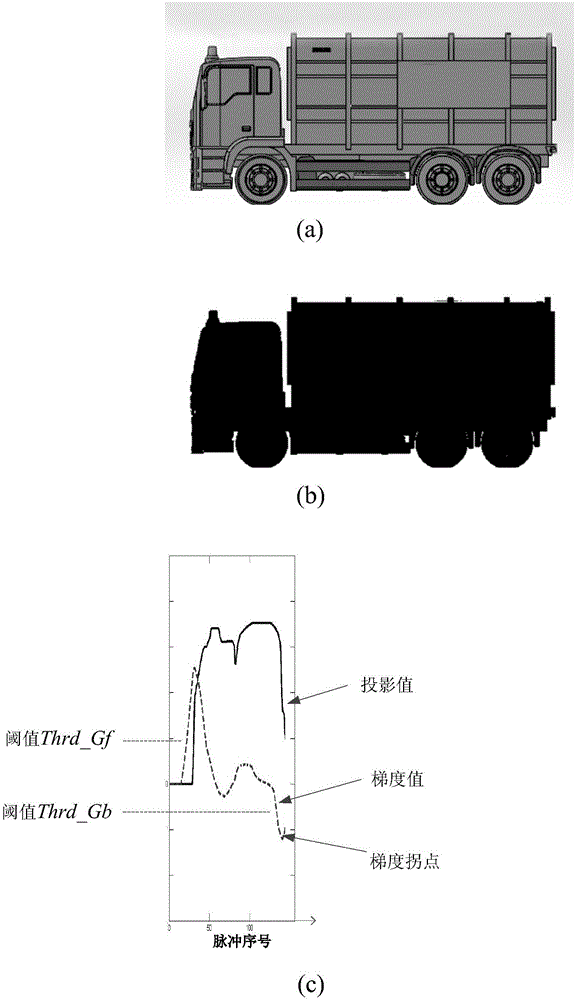

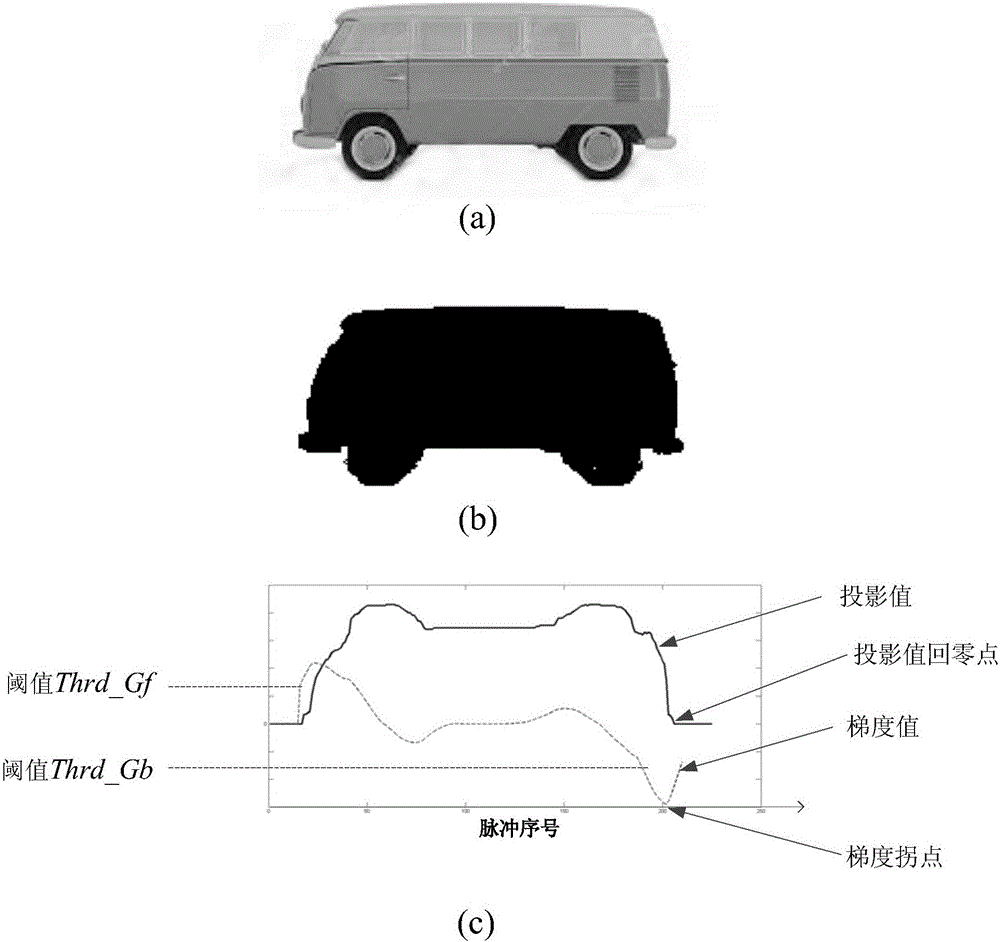

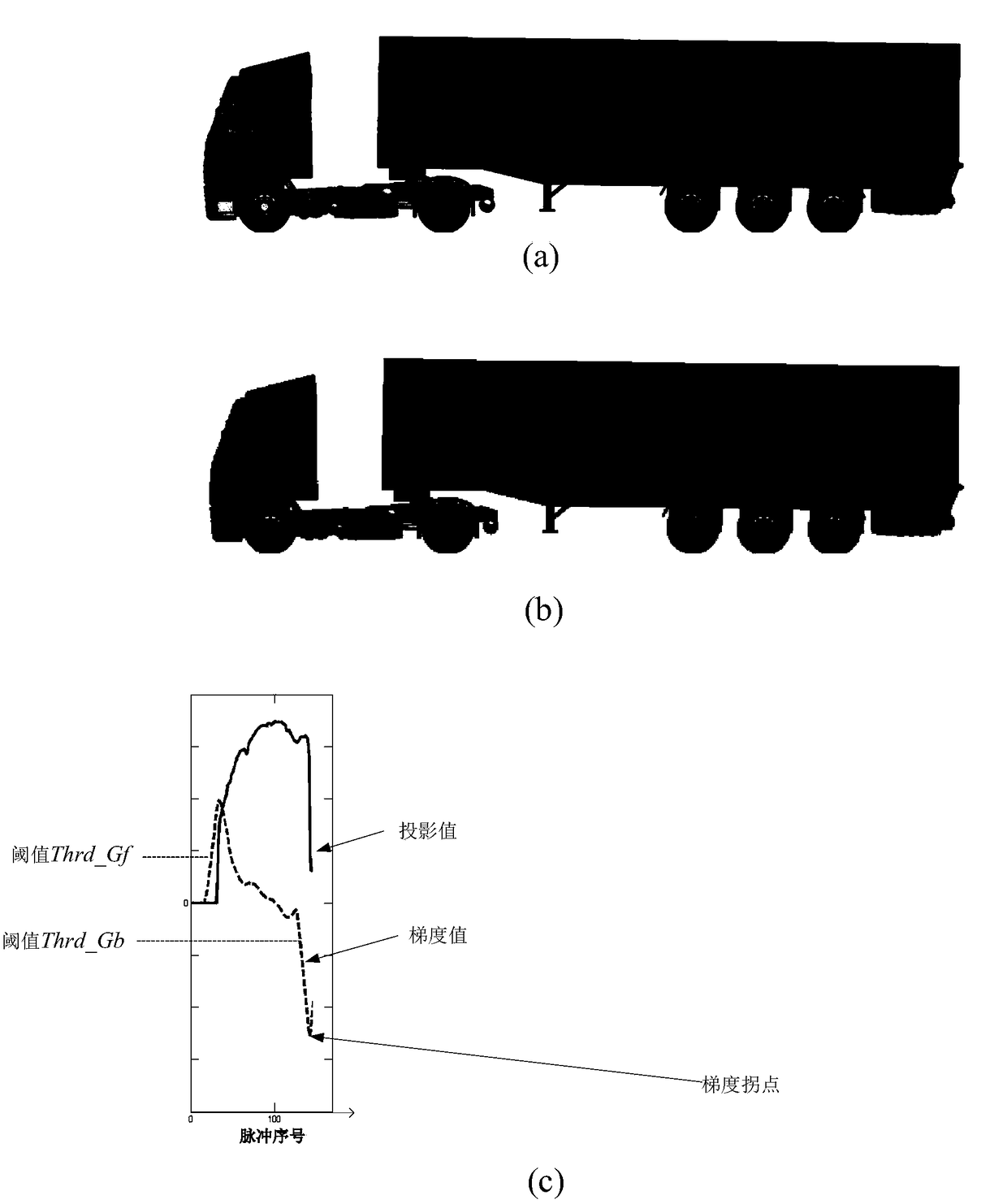

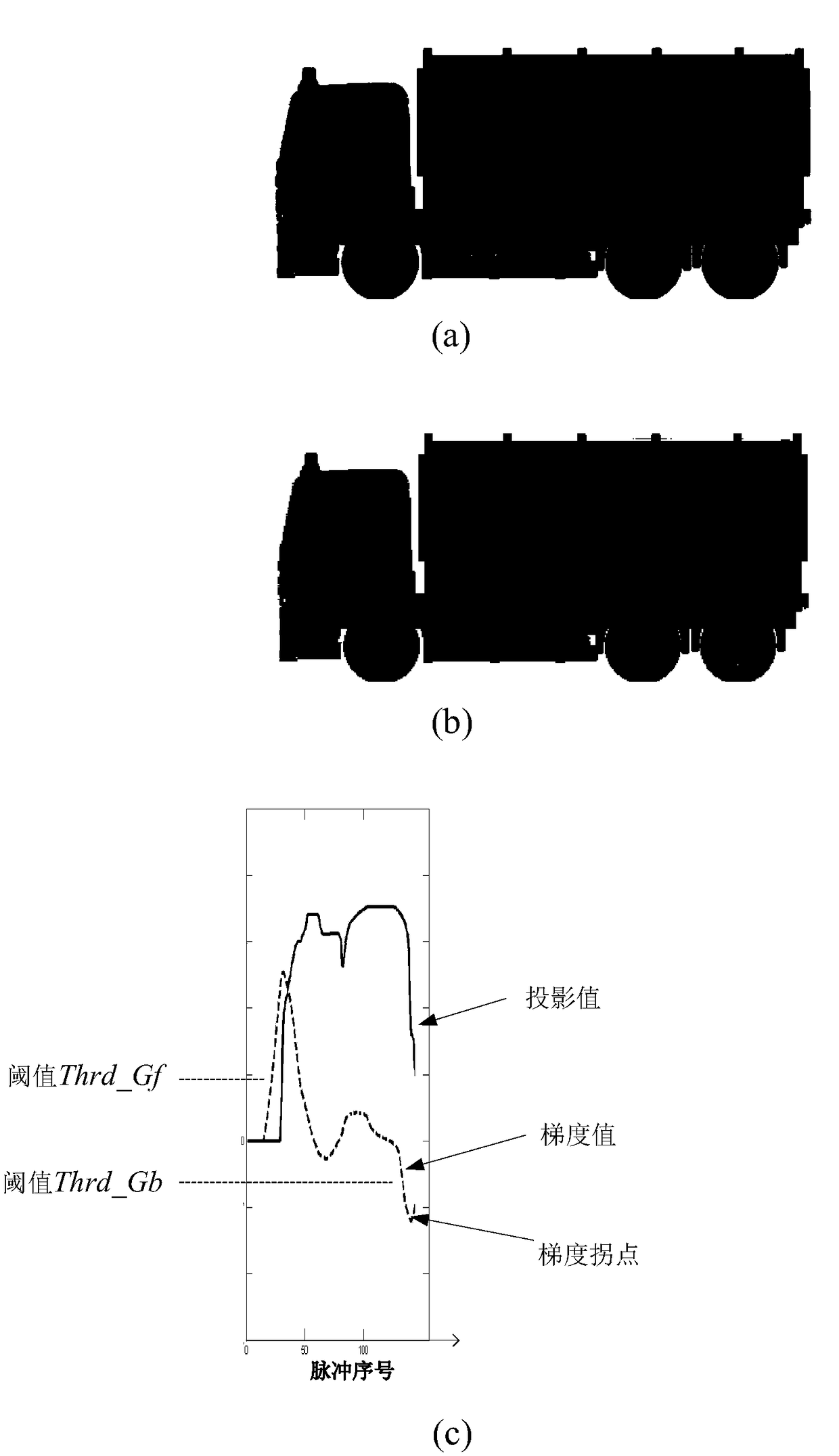

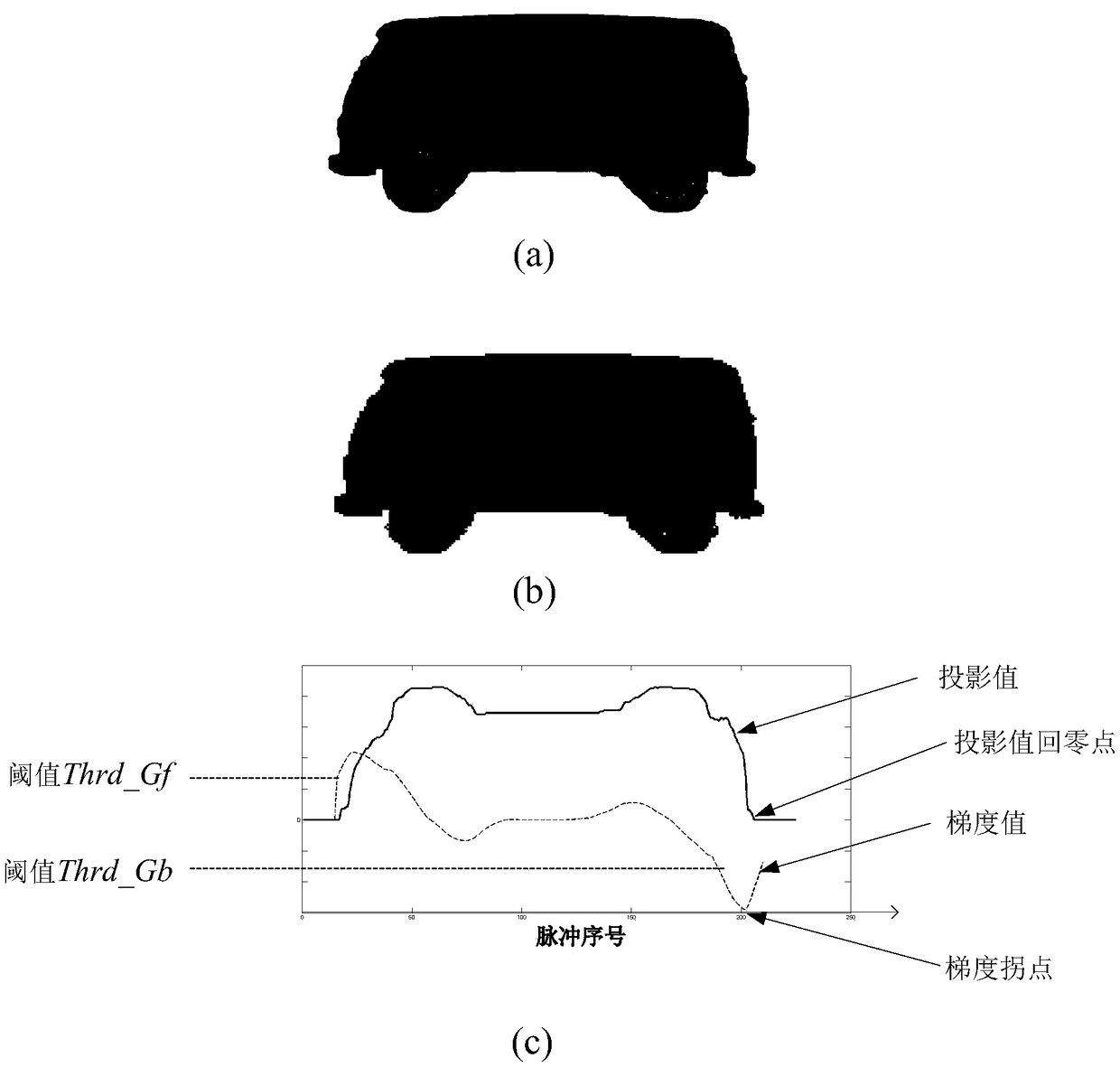

Radiation source control method and rapid pass type security check system

ActiveCN105652332ATo achieve the purpose of inspectionReduce usageNuclear radiation detectionRecognition algorithmSecurity check

The invention discloses a radiation source control method. The method includes the steps of obtaining a detector signal through a radiation beam detector after a radiation source starts to transmit a first radiation beam to scan a detected object, conducting image recognition on the detector signal through an image recognition algorithm so that whether the current scanning position is the boundary position of the detected object or not, and controlling the radiation source to start to transmit a second radiation beam when detecting that the current scanning position is the boundary position of the detected object. The invention further discloses a rapid pass type security check system. By means of the radiation source control method and the rapid pass type security check system, the boundary position of a vehicle cab and a goods area can be accurately and rapidly judged.

Owner:พาวเวอร์สแกน ไฮเทค โค แอลทีดี

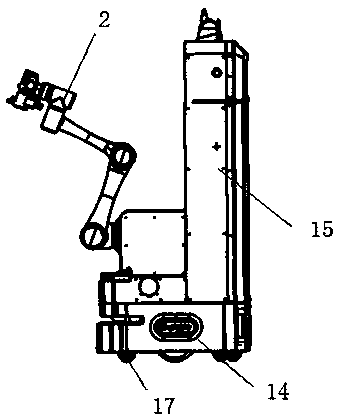

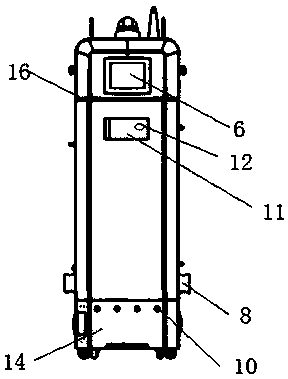

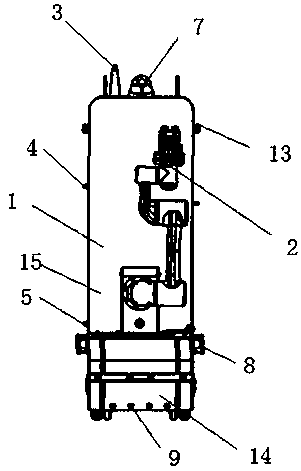

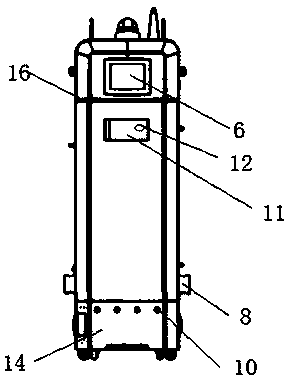

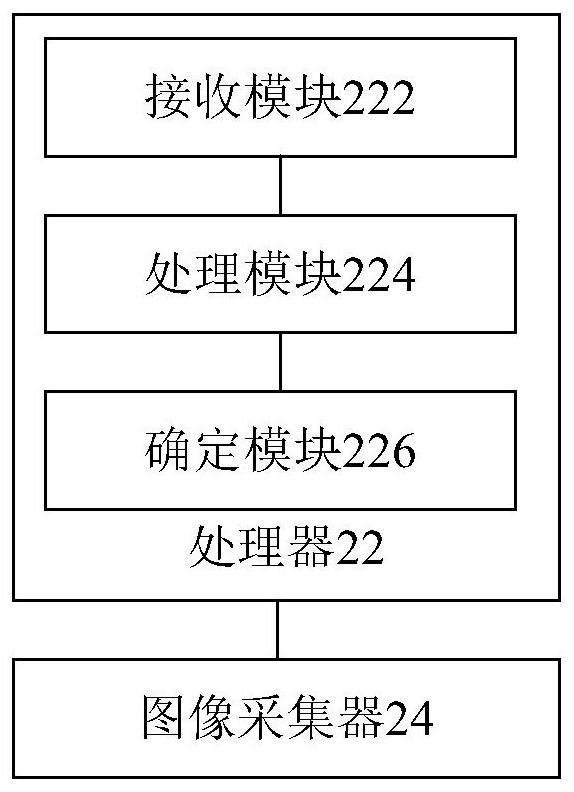

Data center inspection robot

InactiveCN108714886AAvoid electromagnetic radiation damageAvoid lostProgramme-controlled manipulatorVideo monitoringData center

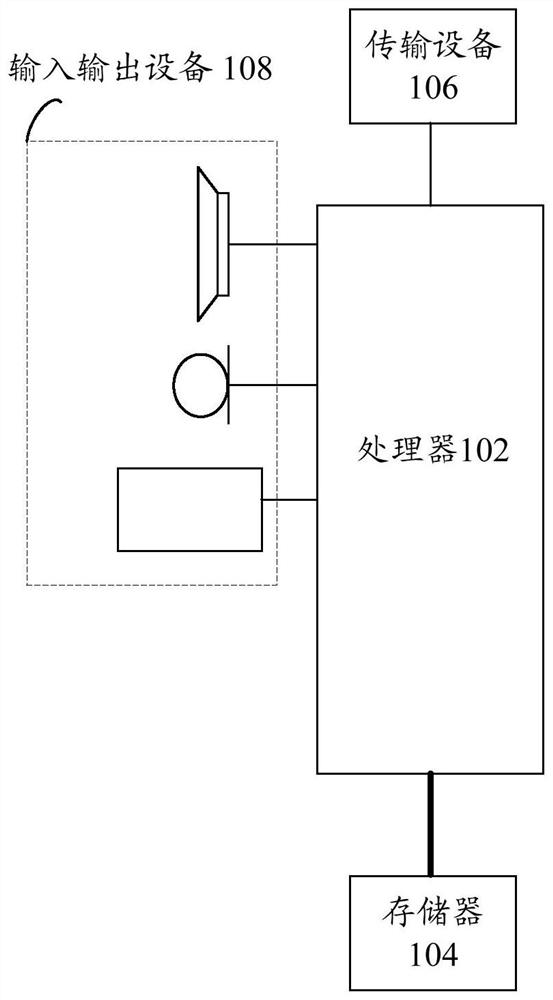

The invention discloses a data center inspection robot. The data center inspection robot comprises a robot body and a robot body driving device, and further comprises a six-degree-of-freedom manipulator, an obstacle avoidance device, a temperature and humidity sensor, a gas sensor, a wind speed sensor, a touch display, a processor, a controller and a monitoring camera. The obstacle avoidance device, the temperature and humidity sensor, the gas sensor, the wind speed sensor, the monitoring camera and the touch display are all connected with the processor; the processor is connected with the controller; the robot body driving device, the six-degree-of-freedom manipulator, the obstacle avoidance device, the temperature and humidity sensor, the gas sensor, the wind speed sensor, the touch display and the monitoring camera are connected with the controller; and the processor is connected with a memory. The data center inspection robot replaces manual inspection, the defects of manual inspection are completely overcome, and a video avoidance system and various sensors do not need to be mounted in a machine room, so that the construction cost and the management cost of the machine room are greatly lowered.

Owner:桑瑞思医疗科技有限公司

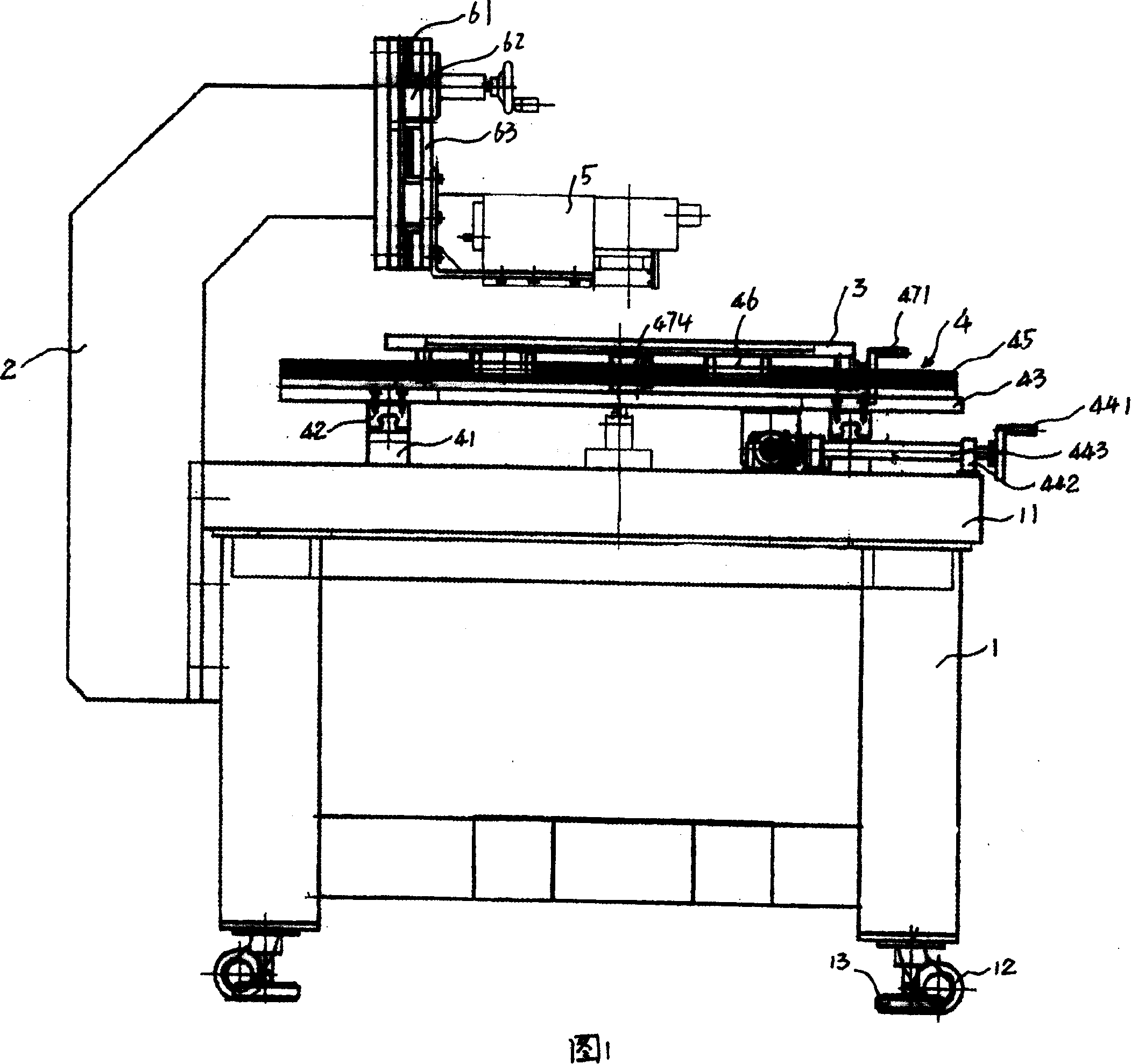

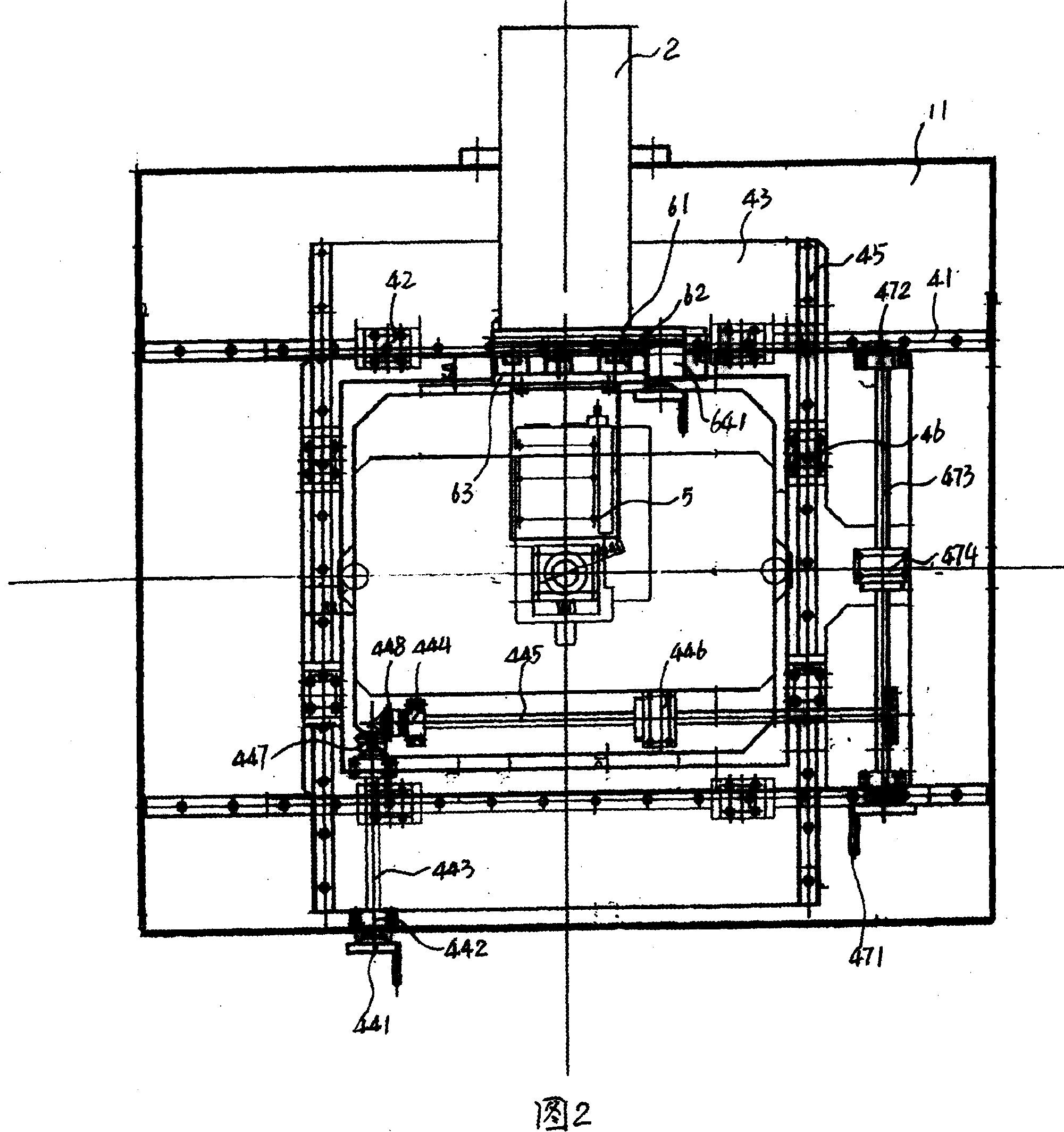

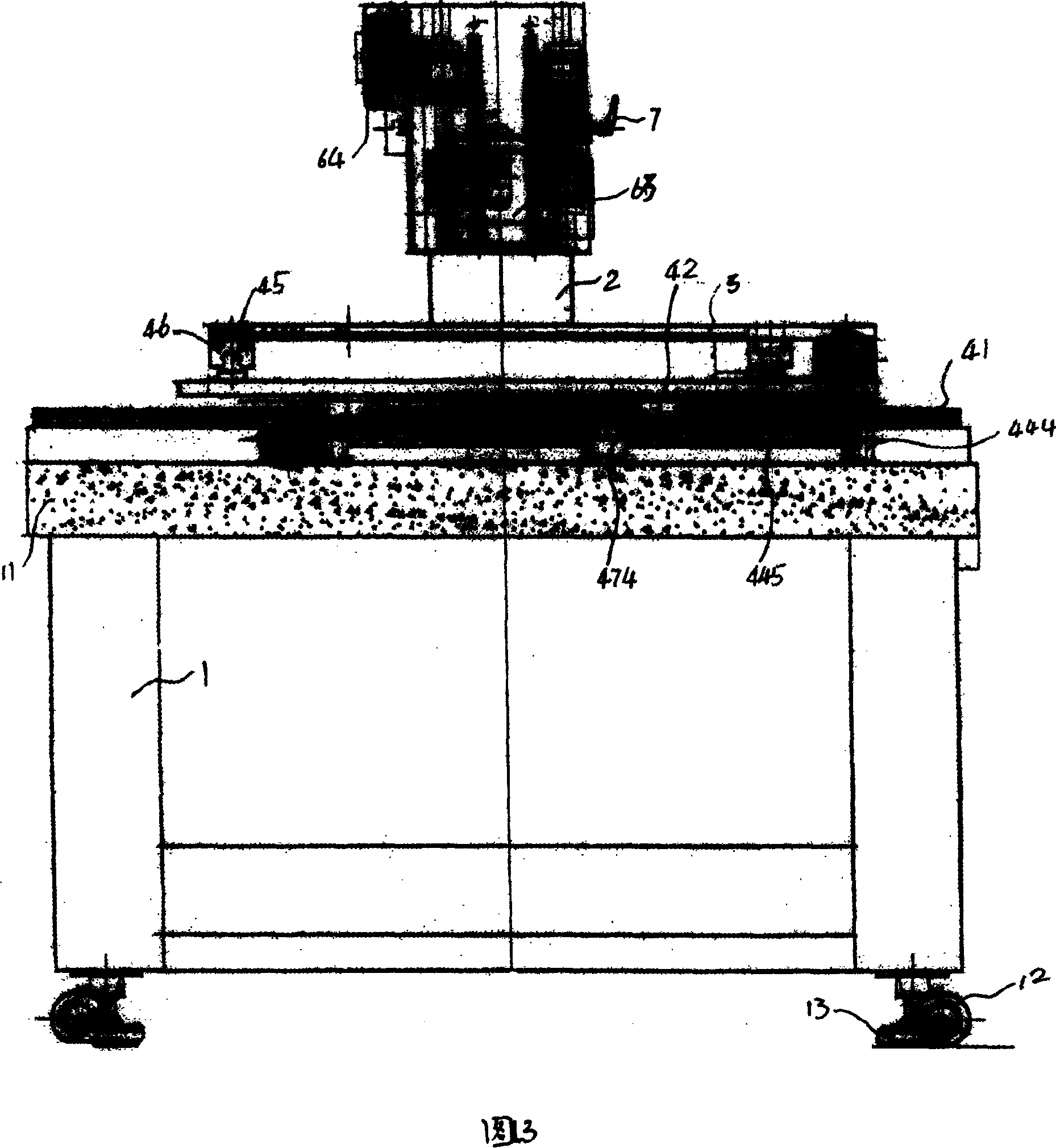

Detection system for large-sized panel display device

InactiveCN1995986AImprove accuracy and stabilityReduce damage and scratchesElectrical testingMaterial analysis by optical meansMeasurement deviceLiquid crystal

The inspection system of big panel display comprises the base, extendable head fastened on the base, moving table on the base platform that can move along the X and Y coordinates, microscope inspection device on the head that can alight. Putting the display on the moving table, it can realize X and Y movement of the horizontal and vertical lead screw rolling ball mechanism. It can reach the goal of inspection. It improves the moving precision and stability. Free from moving of the sample, it can lower the possibility of damage and scratch. The microscope can move up and down, realizing high power observation of big dimension and small dimension measurement. The measurement device can use partial automatic device with independent image and measurement system. It is suitable for large LED base plate inspection.

Owner:CREATIVE INSPECTION SYST

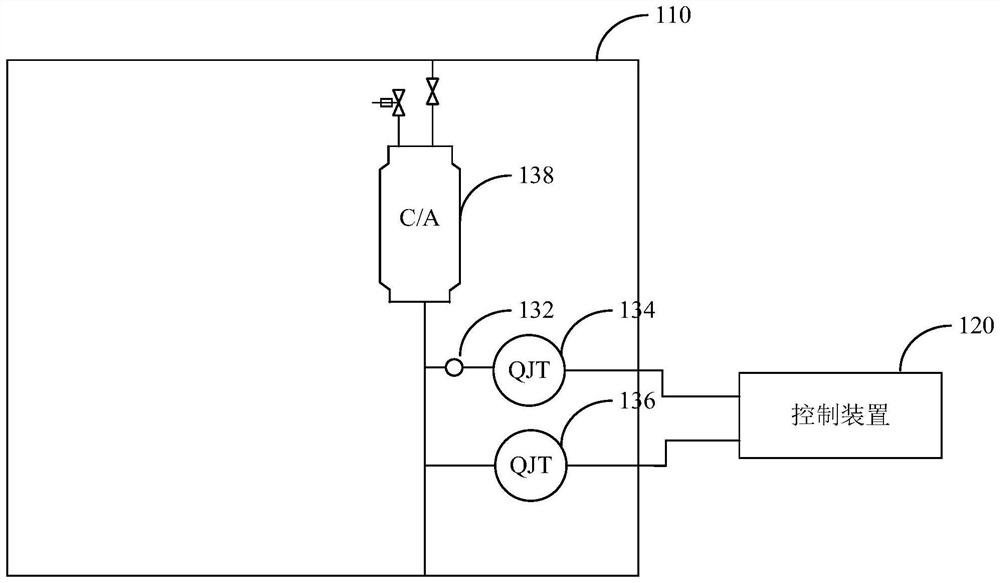

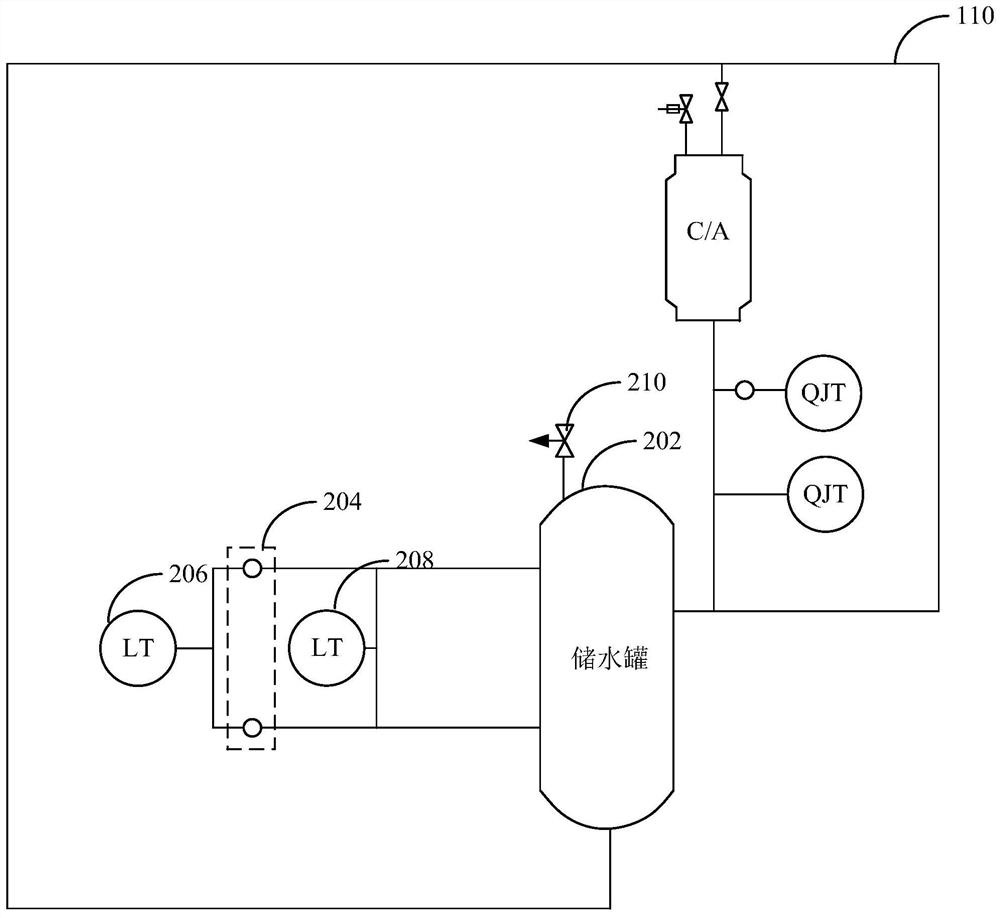

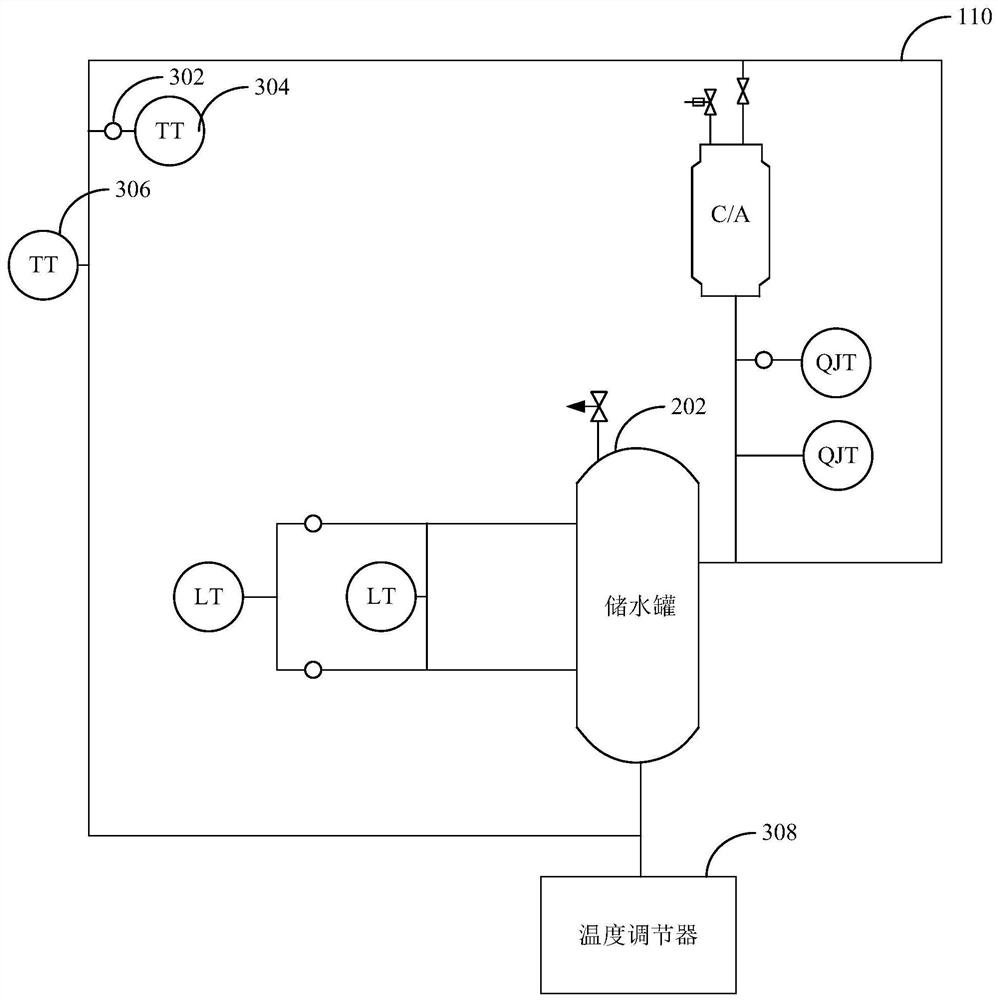

Instrument inspection system

PendingCN114018308ATo achieve the purpose of inspectionImprove verification efficiencyInstrumentsClosed loopEngineering

Owner:DALI BUREAU OF ULTRA HIGH VOLTAGE TRANSMISSION CO CHINA SOUTHERN POWER GRID CO LTD

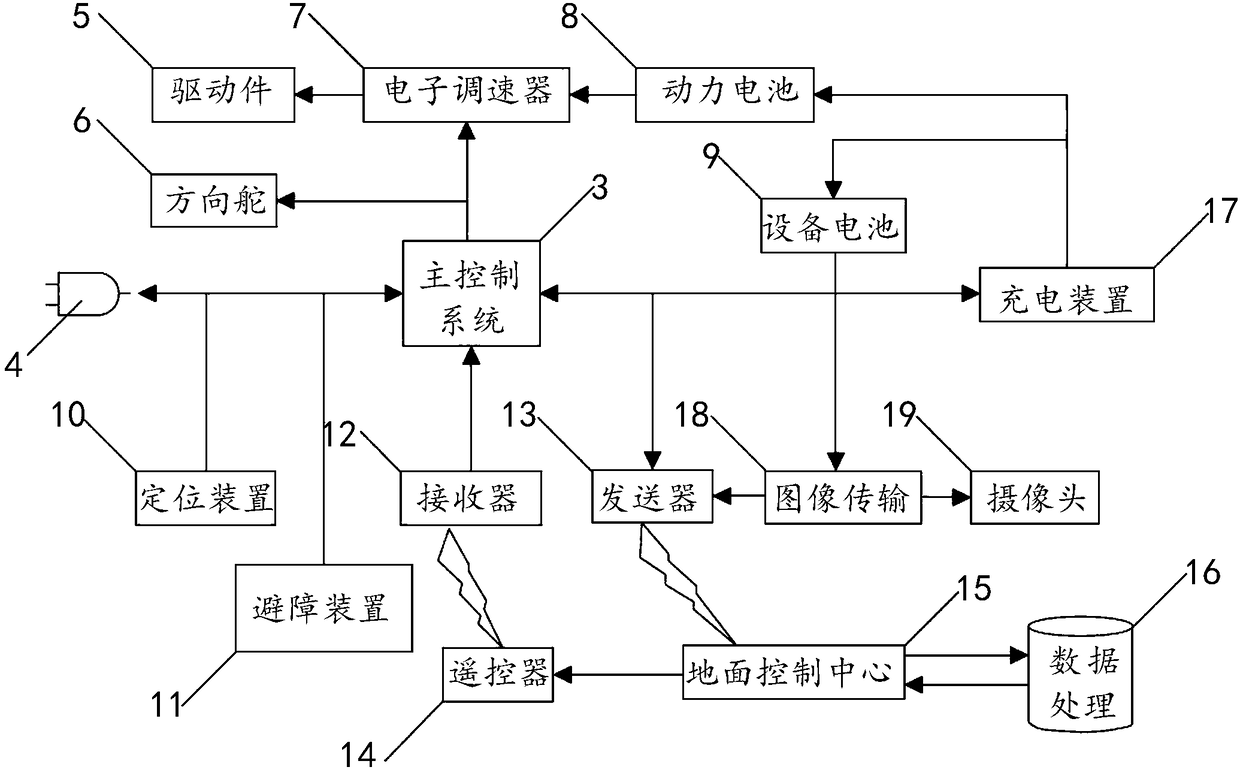

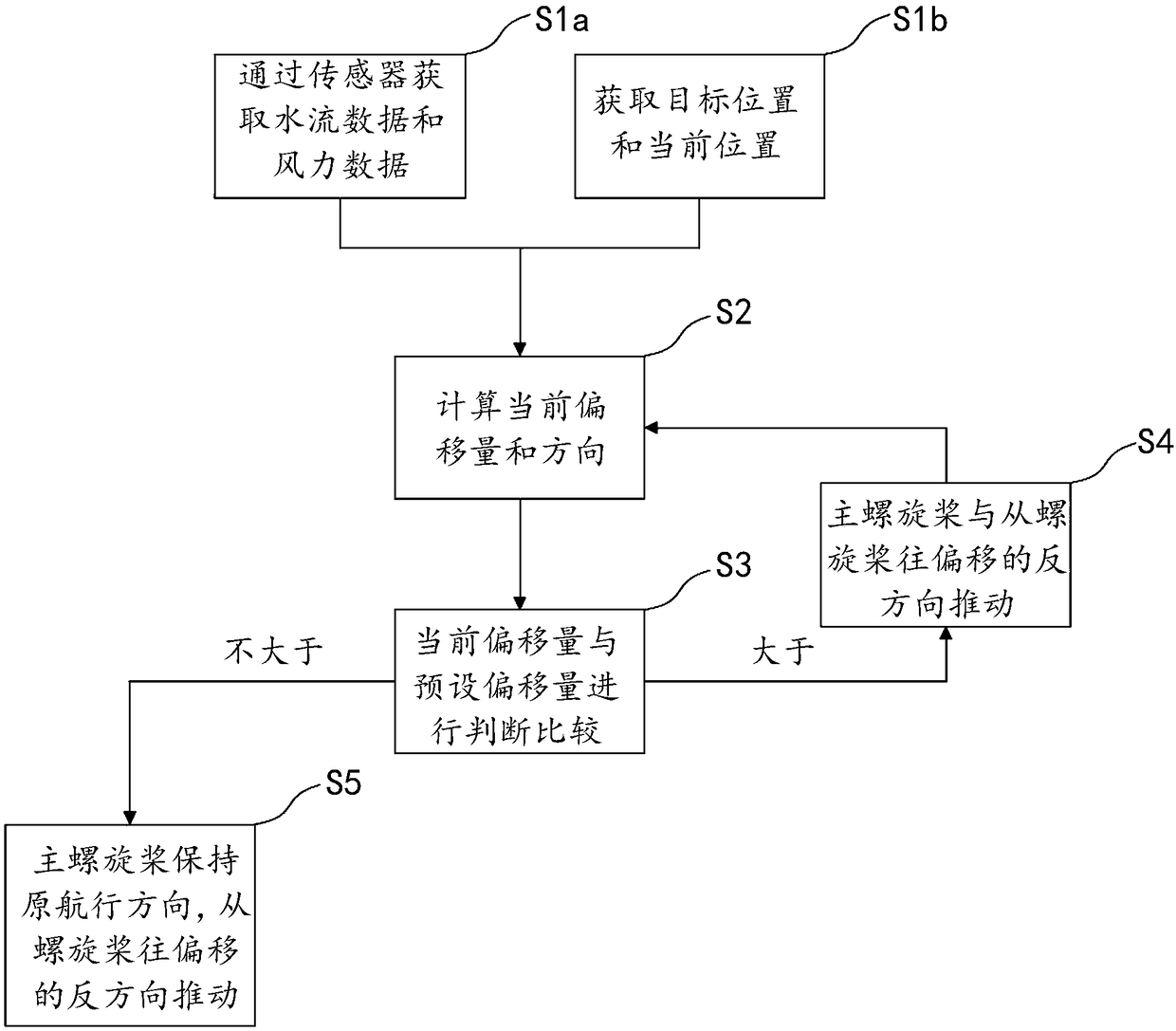

Water body monitoring and restoring multifunctional robot and route and position correction method thereof

InactiveCN108312145AWide range of applicationsEasy maintenanceProgramme-controlled manipulatorPosition/course control in two dimensionsEmbedded systemPower storage

The invention discloses a water body monitoring and restoring multifunctional robot which comprises a main floating body and functional floating bodies. The main floating body comprises a master control system, a power device and a power storage device, the master control system comprises a transmission device and a positioning device, the power device comprises a driving piece and a rudder, and the master control system and function control systems of the functional floating bodies are in signal connection or electric connection. According to the robot, the main floating body is used as a center, the main floating body is combined with other functional floating bodies to form a floating island robot, selective combination can be carried out on water areas with different needs, the application face is wide, and maintenance is convenient; the floating island robot can be remotely controlled through the master control system, the intelligent degree is high, the power device provides thefunction of automatic walking along a preset route for the floating island robot, the aim of patrolling rivers and lakes is achieved, and the disadvantages of a traditional floating island is overcome.

Owner:广州东烁科技有限公司

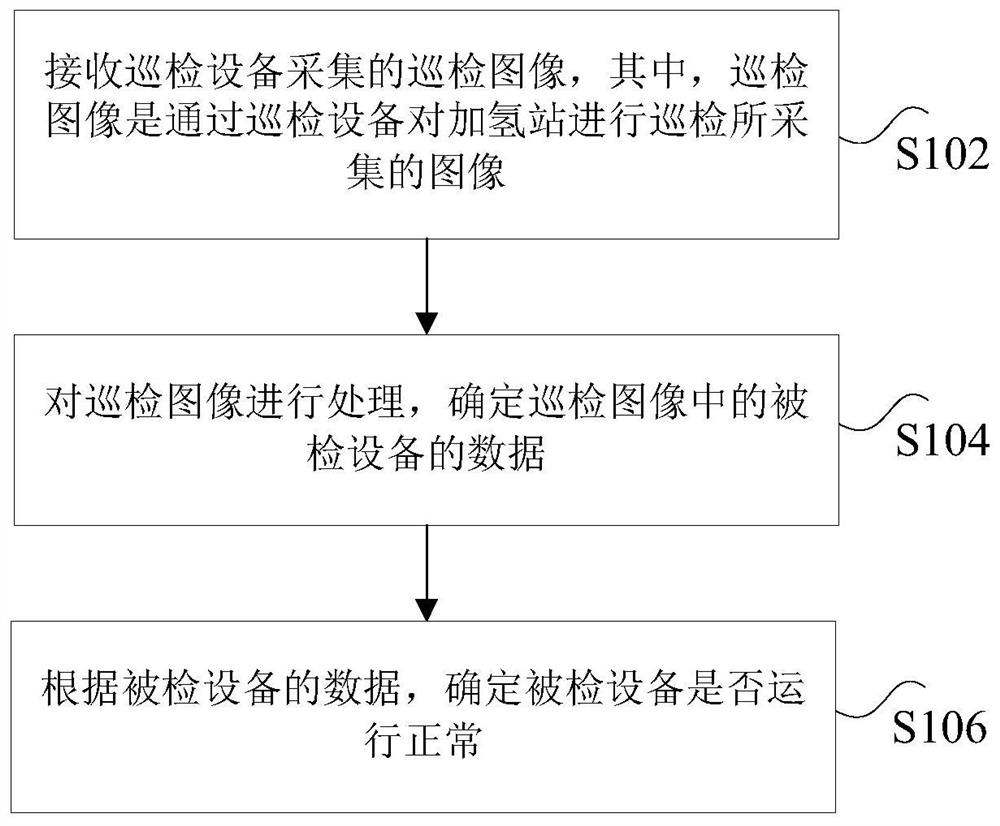

Hydrogen refueling station inspection data processing method and hydrogen refueling station inspection device

PendingCN111784865ATo achieve the purpose of inspectionReduce missed detection rateChecking time patrolsRegistering/indicating working of machinesReal-time computingData processing

Owner:北京融链科技有限公司 +1

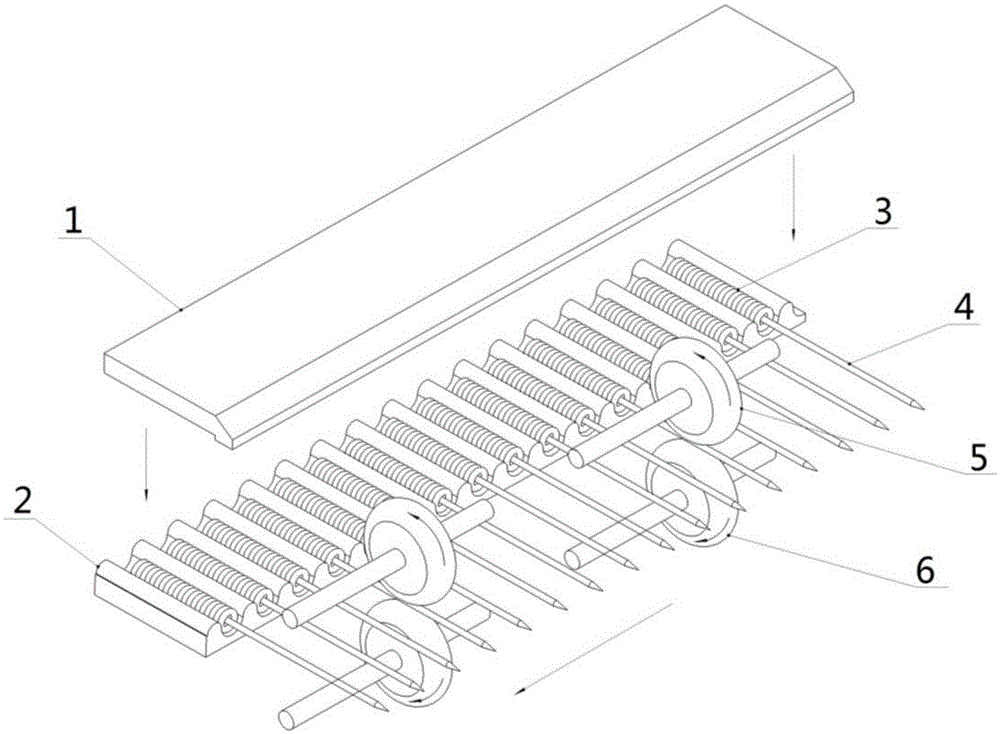

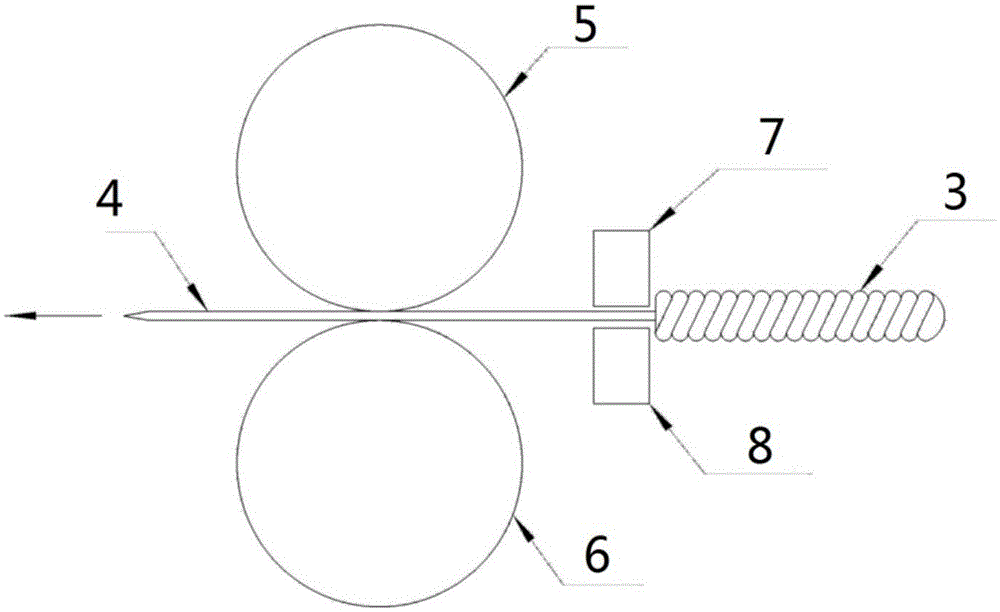

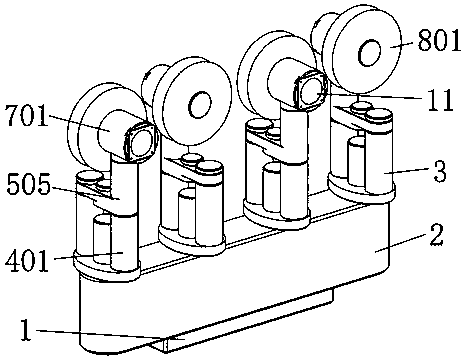

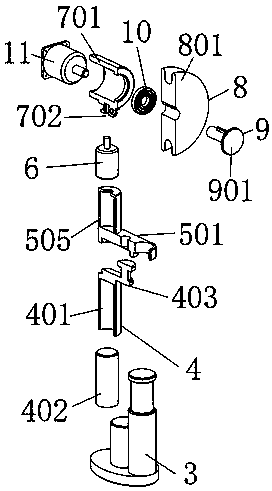

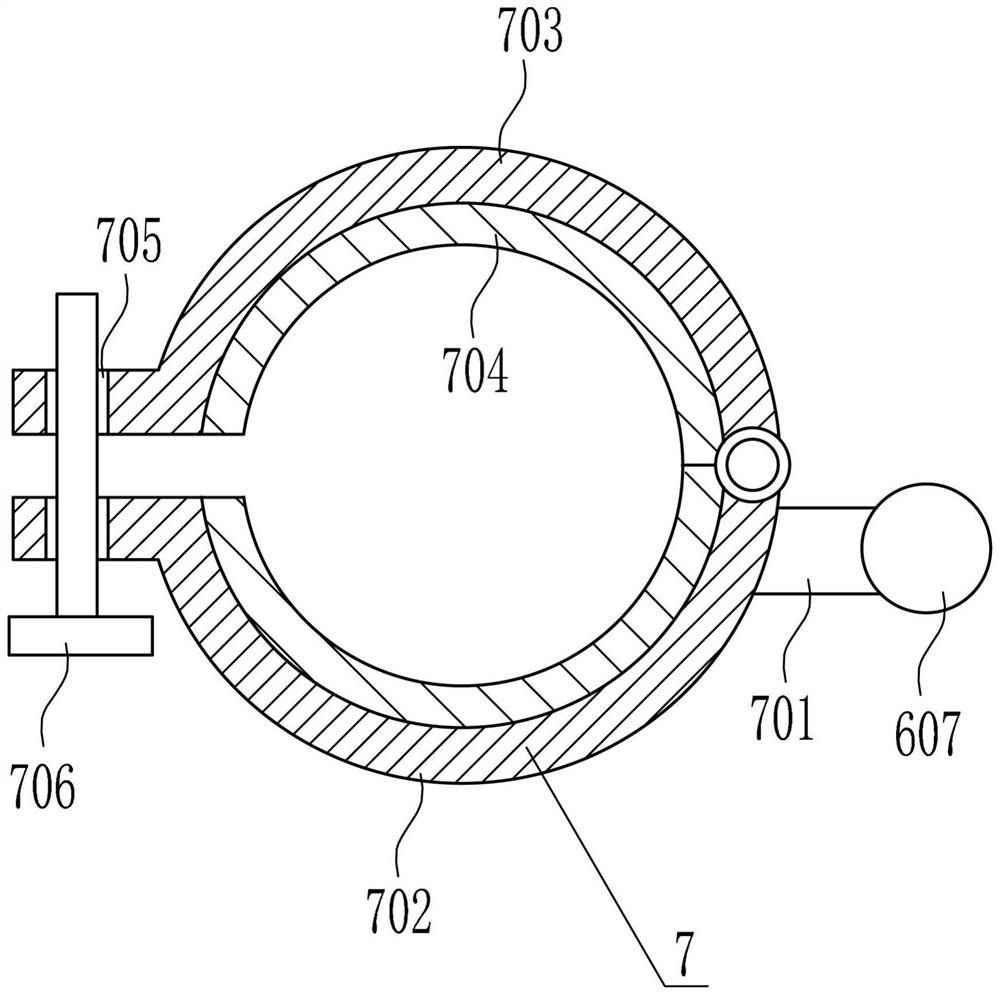

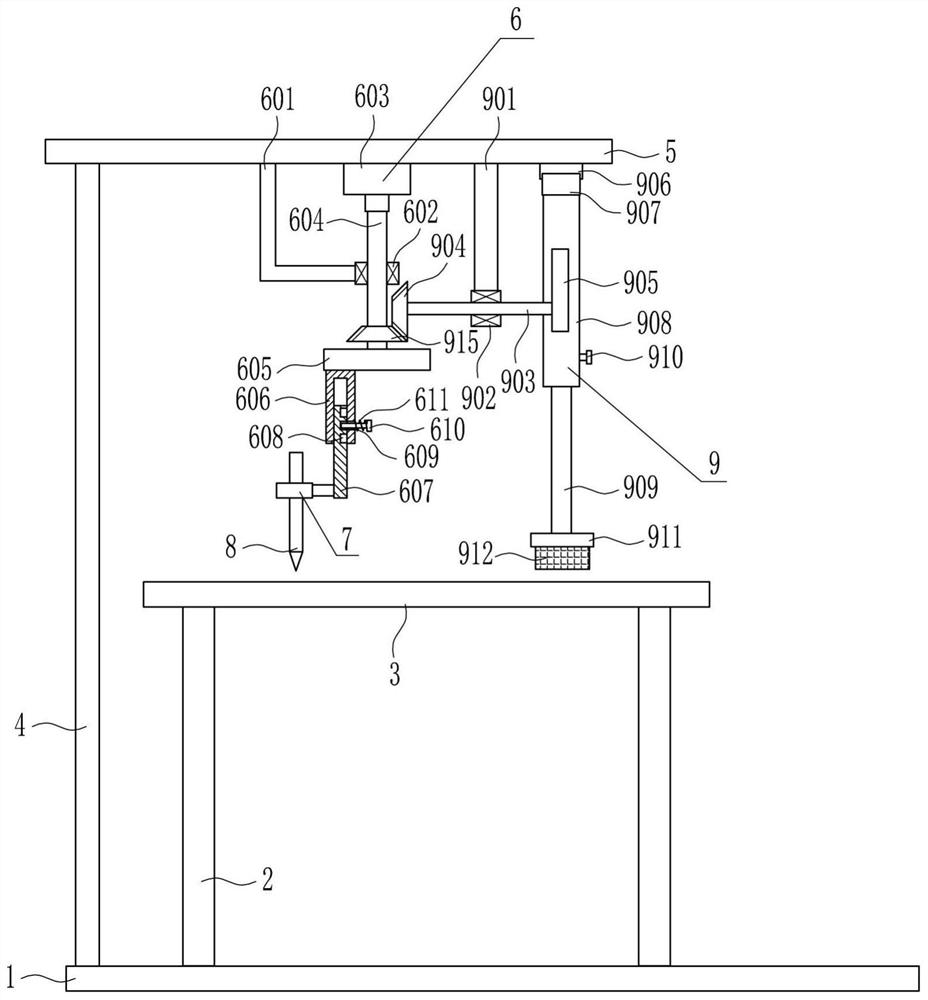

Automatic drawing machine for inspecting stem to needle body connection firmness and application method of automatic drawing machine

ActiveCN105158156AAutomatic removalAutomated inspectionUsing mechanical meansMaterial analysisElectric machineEngineering

The invention discloses an automatic drawing machine for inspecting stem to needle body connection firmness and an application method of the automatic drawing machine and belongs to the technical field of firmness inspection of acupuncture needles. The automatic drawing machine comprises a conveying belt, drawing structures, a storage trough and a drive part. Retaining plates include an upper retaining plate and a lower retaining plate. The plane that the upper retaining plate and the lower retaining plate locate in is parallel to that of the conveying belt. A distance (or gap) between the upper retaining plate and the lower retaining plate is greater than the diameter of a needle body and less than the diameter of a stem. A midpoint of the distance between the upper retaining plate and the lower retaining plate and a direction of the needle body are collinear. Rollers include upper rollers and lower rollers in contact with each other; the drawing structures are evenly distributed on one side of the conveying belt; the drive part comprises a motor and a processor; each group of upper and lower rollers is driven by one motor; the conveying belt is driven by another motor; all the motors are connected with the processor; the storage trough is disposed below the other end of the conveying belt. The automatic drawing machine is capable of inspecting firmness of each acupuncture needle and has an auto-sorting function.

Owner:马鞍山邦德医疗器械有限公司

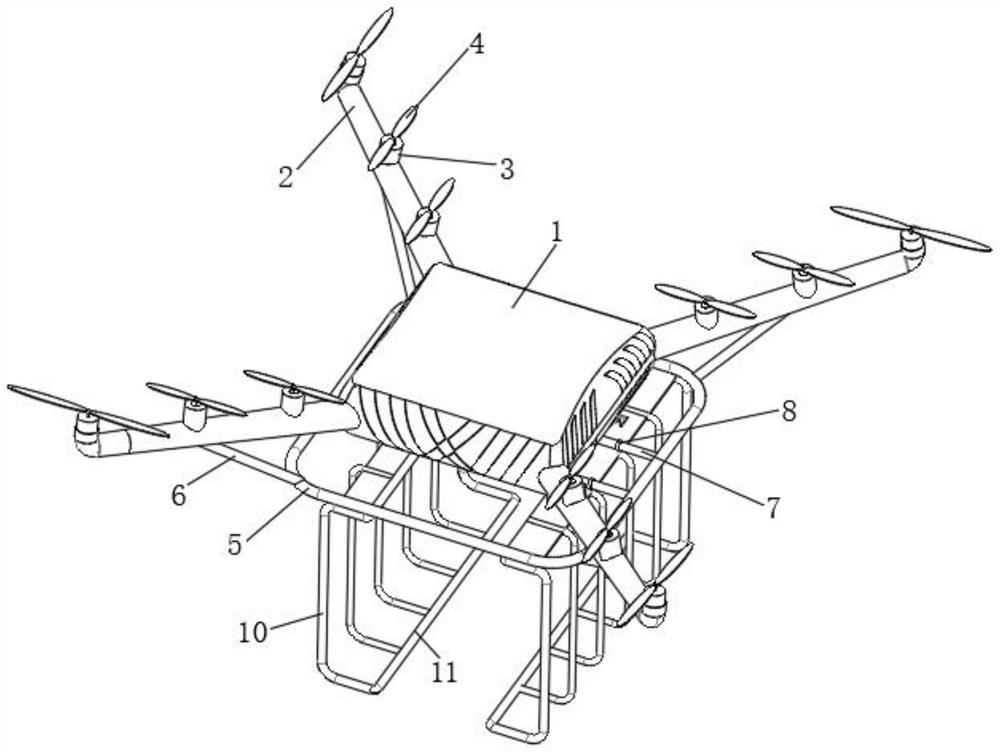

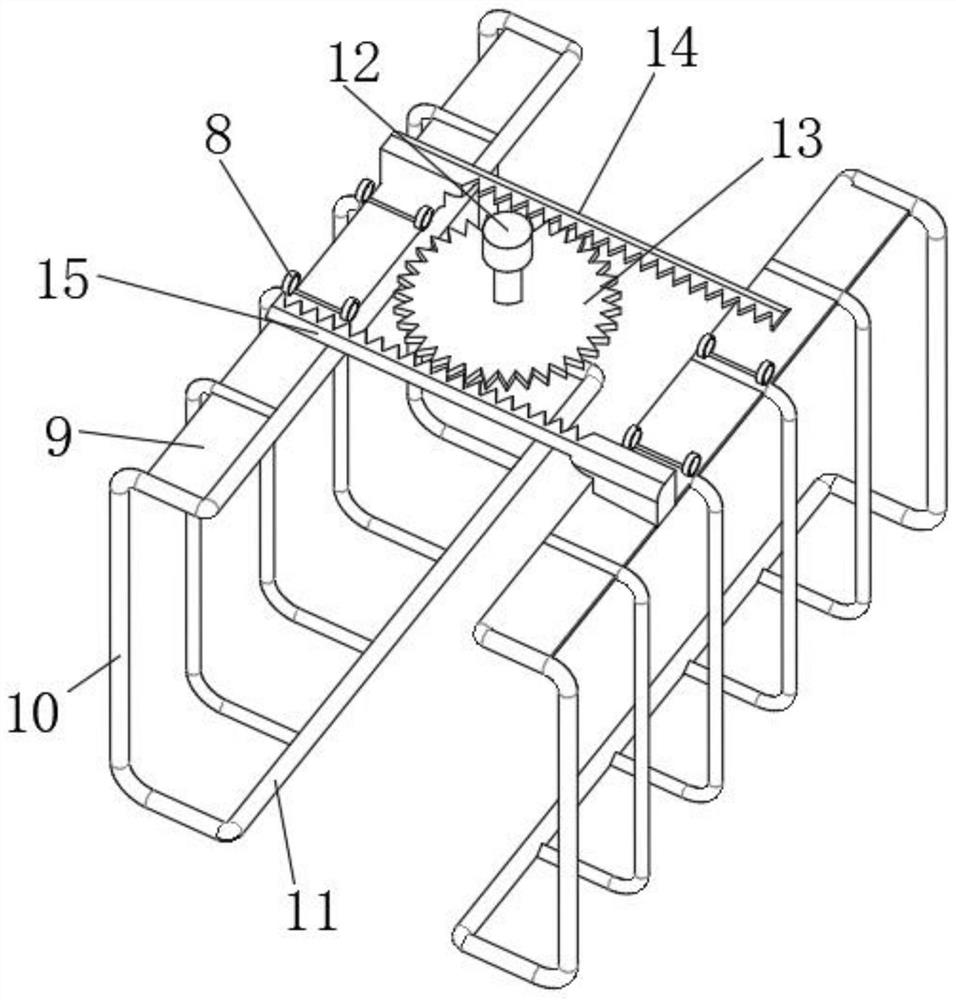

Multifunctional routing inspection unmanned aerial vehicle

PendingCN112173110AIncrease loading capacityImprove transportation efficiencyRemote controlled aircraftFreight handlingGear wheelUncrewed vehicle

Owner:南京拓恒无人系统研究院有限公司

Radiation source control method and rapid-pass security check system

ActiveCN108897055ATo achieve the purpose of inspectionReduce usageNuclear radiation detectionRecognition algorithmSecurity check

The invention discloses a radiation source control method which comprises after the radiation source starts to emit the first radiation beam to scan the object to be detected, acquiring a detector signal through a radiation beam detector; carrying out the image recognition processing on the detector signals through an image recognition algorithm to detect whether the current scanning position is the boundary position of the object to be detected; and when detecting that the current scanning position is the boundary position of the object to be detected, controlling the radiation source to start to emit the second radiation beam. The invention further discloses a rapid-pass security check system. By means of the method and the device, the boundary position of the vehicle cab and the cargo area can be determined accurately and rapidly.

Owner:พาวเวอร์สแกน ไฮเทค โค แอลทีดี

Gastroscopic assembly pipe

InactiveCN103479318AGood tear strengthExtended service lifeGastroscopesOesophagoscopesOperation timeMaterials science

The invention discloses a gastroscopic assembly pipe, which comprises a sleeve pipe, a first stainless steel woven net pipe, a second stainless steel woven net pipe, a third stainless steel woven net pipe, a spring pipe, a connecting ring, traction fine elastic pipes and an equipment connecting joint, wherein the first stainless steel woven net pipe is sheathed on the spring pipe, the sleeve pipe is sheathed on the first stainless steel woven net pipe, the front section of the sleeve pipe is connected with the connecting ring, the tail end of the sleeve pipe is connected with the equipment connecting joint, the sleeve pipe is of a step structure and is separated into a front section, a middle section and a tail section, the second stainless steel woven net pipe is arranged at the middle section and the tail section, the second stainless steel woven net pipe is sheathed on the first stainless steel woven net pipe, the third stainless steel woven net pipe is arranged at the tail section and is sheathed on the second stainless steel woven net pipe, and the traction fine pipes are arranged in the first stainless steel woven net pipe. The assembly pipe has the advantages that the bending degree is high, the operation is flexible, the installation is convenient, the missing of diseases is avoided, the operation time is shortened, and the diagnosis capability and diagnosis efficiency are favorably improved.

Owner:詹姆士·庞

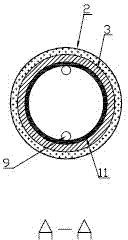

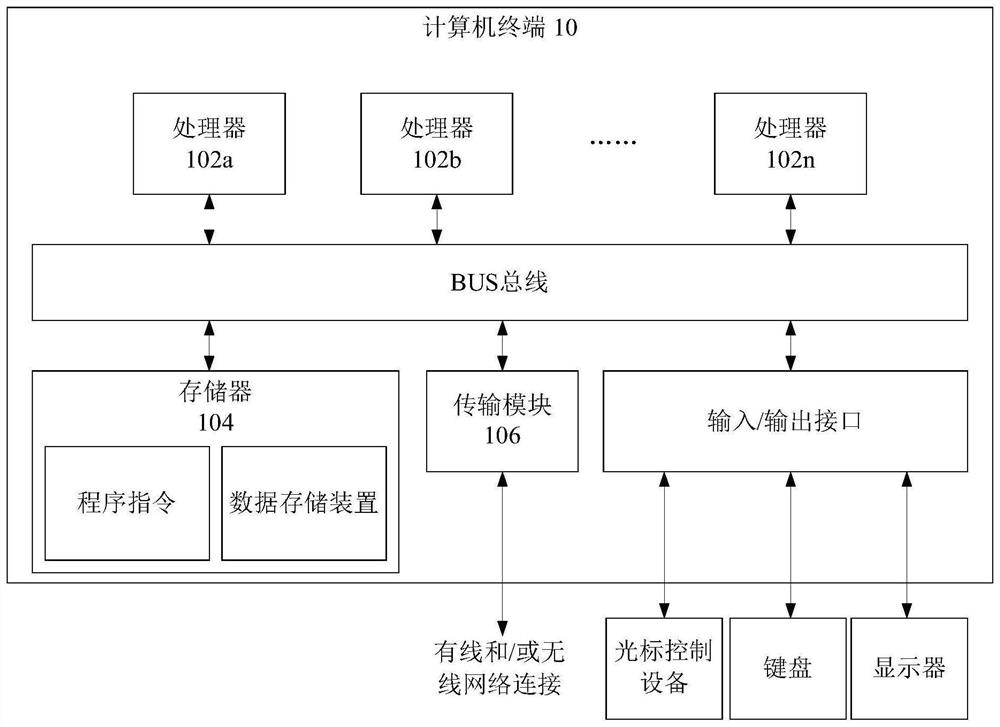

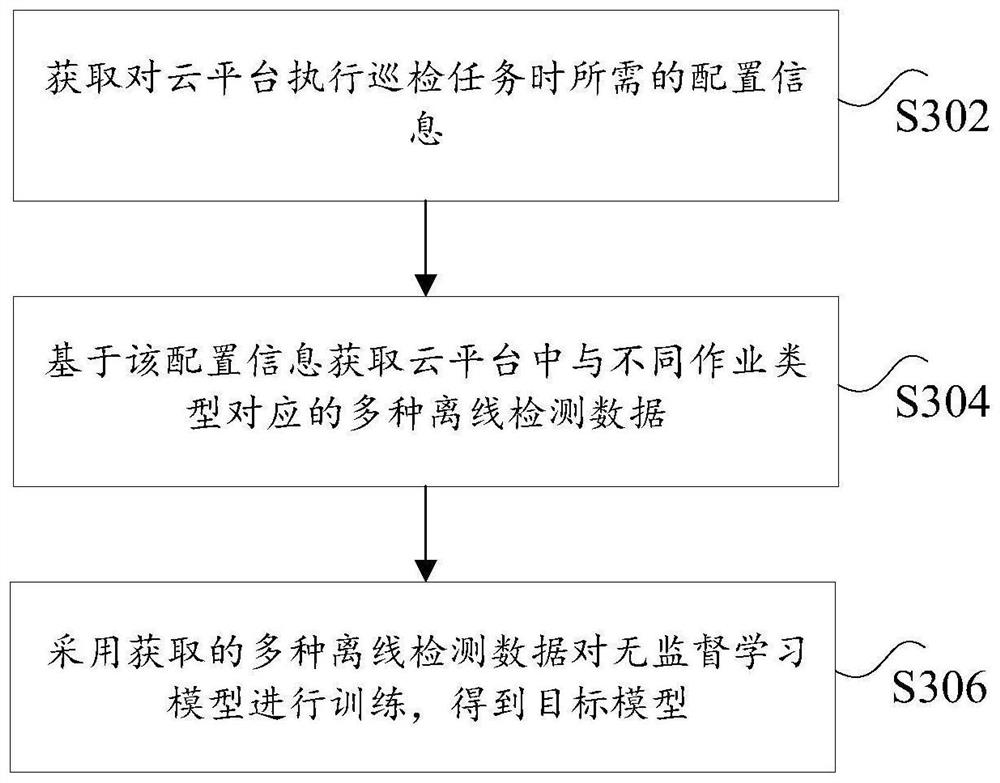

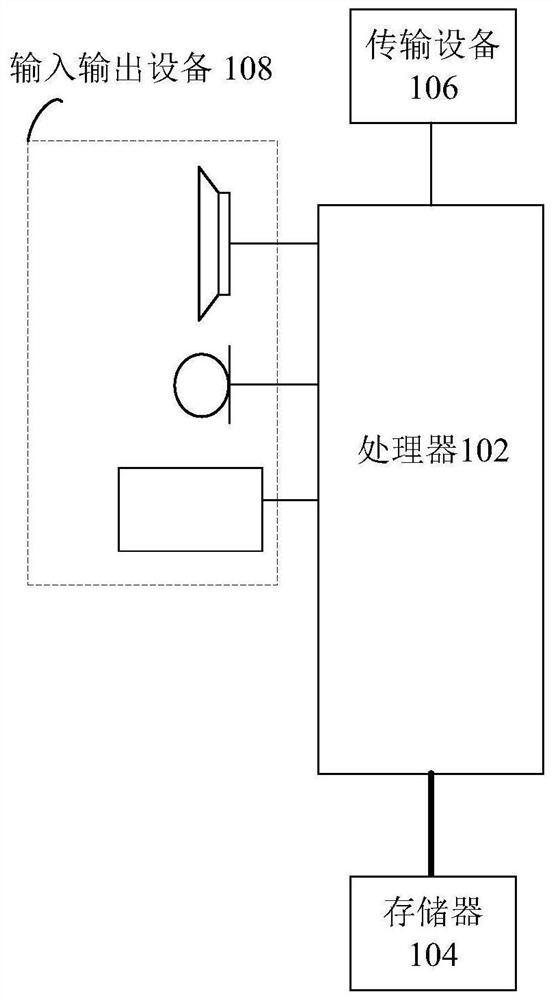

Inspection method of cloud platform, electronic equipment and nonvolatile storage medium

PendingCN113313280AEfficient and reliable inspectionTo achieve the purpose of inspectionForecastingCharacter and pattern recognitionReal-time computingUnsupervised learning

The invention discloses an inspection method of a cloud platform, electronic equipment and a nonvolatile storage medium. The method comprises the following steps: acquiring configuration information required for executing an inspection task on a cloud platform; acquiring various detection data corresponding to different job types in the cloud platform based on the configuration information; training an unsupervised learning model by adopting the obtained multiple detection data to obtain a target model; acquiring a data stream from a target data source; and inputting the data stream into the target model for analysis to obtain an inspection result of the data stream. The technical problem that the use condition and stability of the cloud platform cannot be effectively detected is solved.

Owner:ALIBABA SINGAPORE HLDG PTE LTD

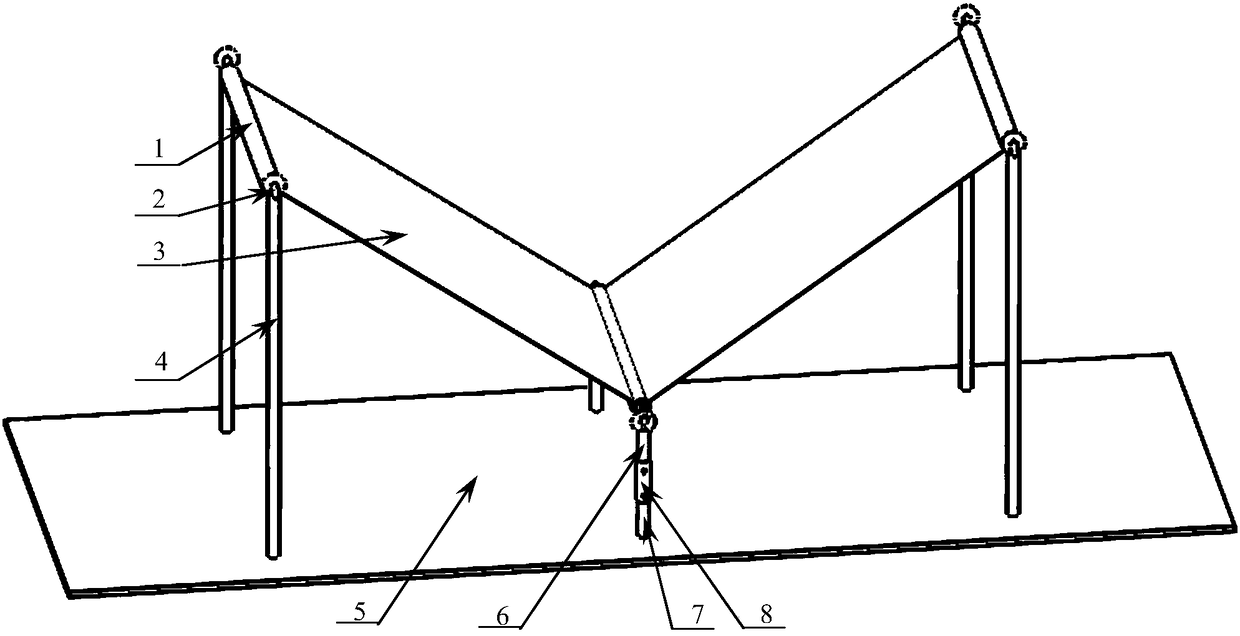

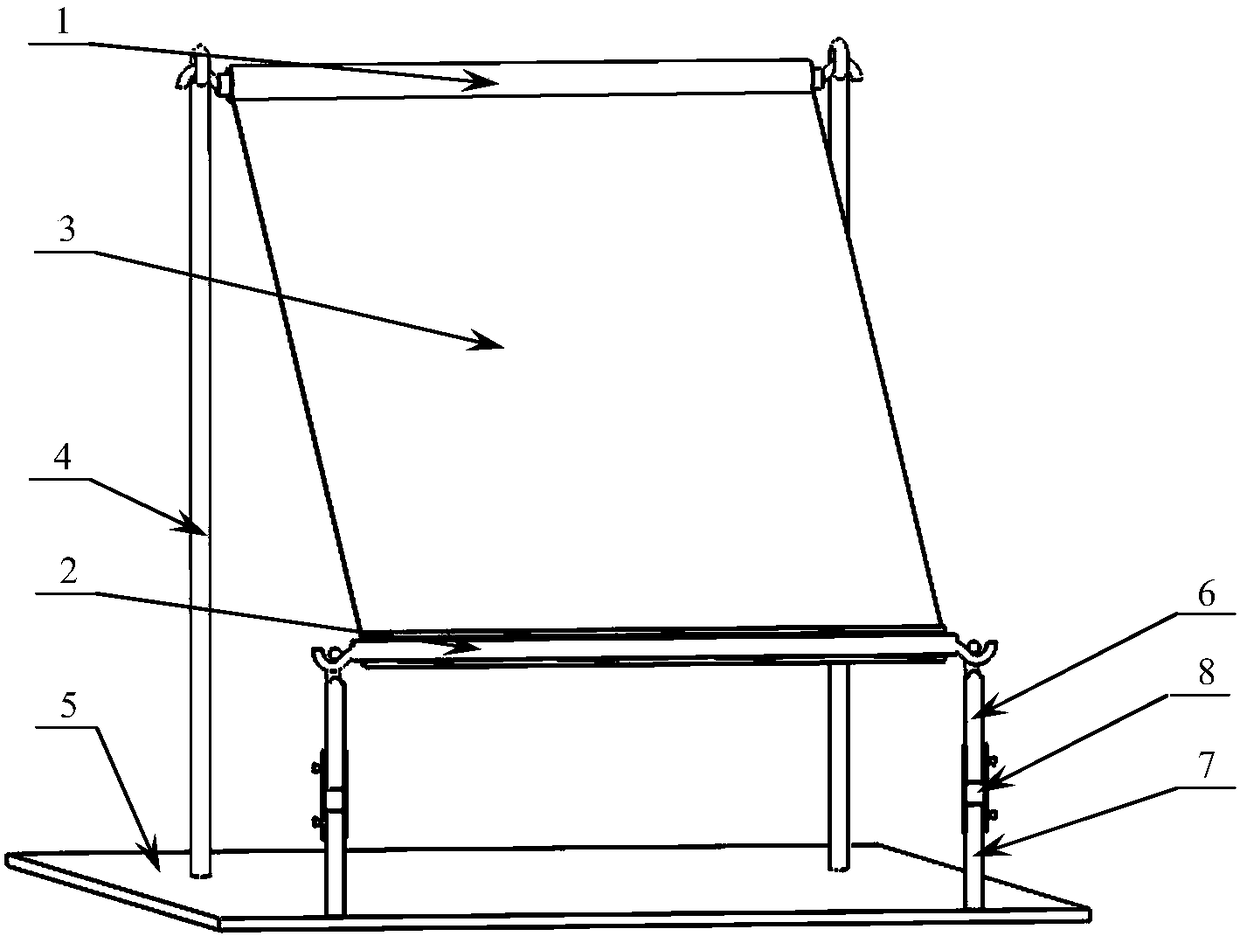

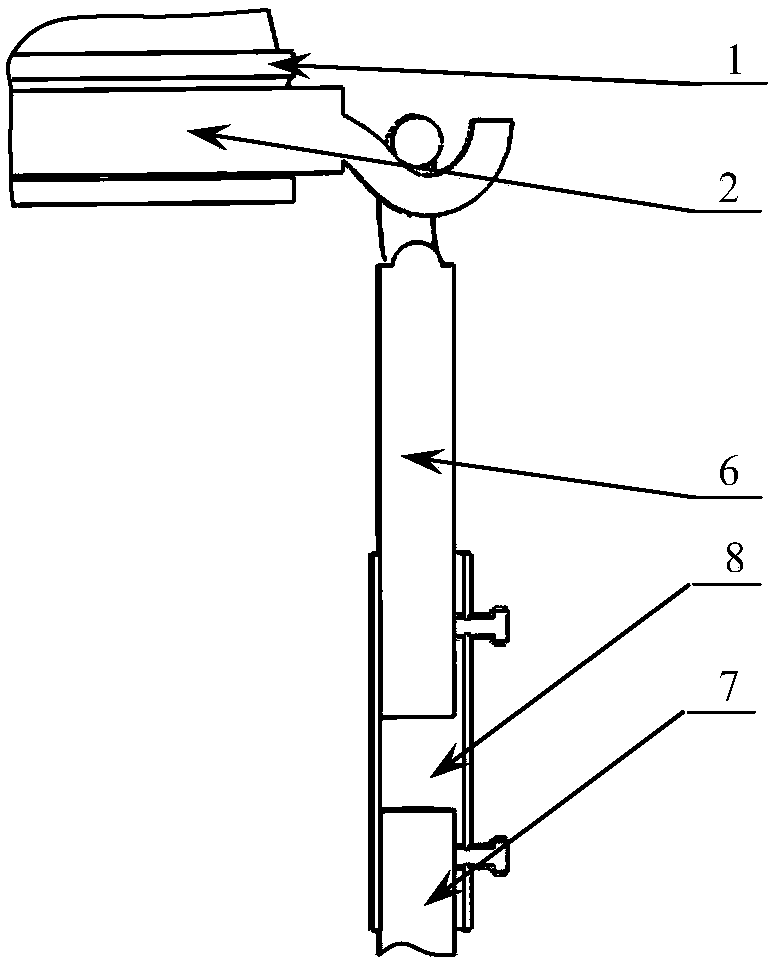

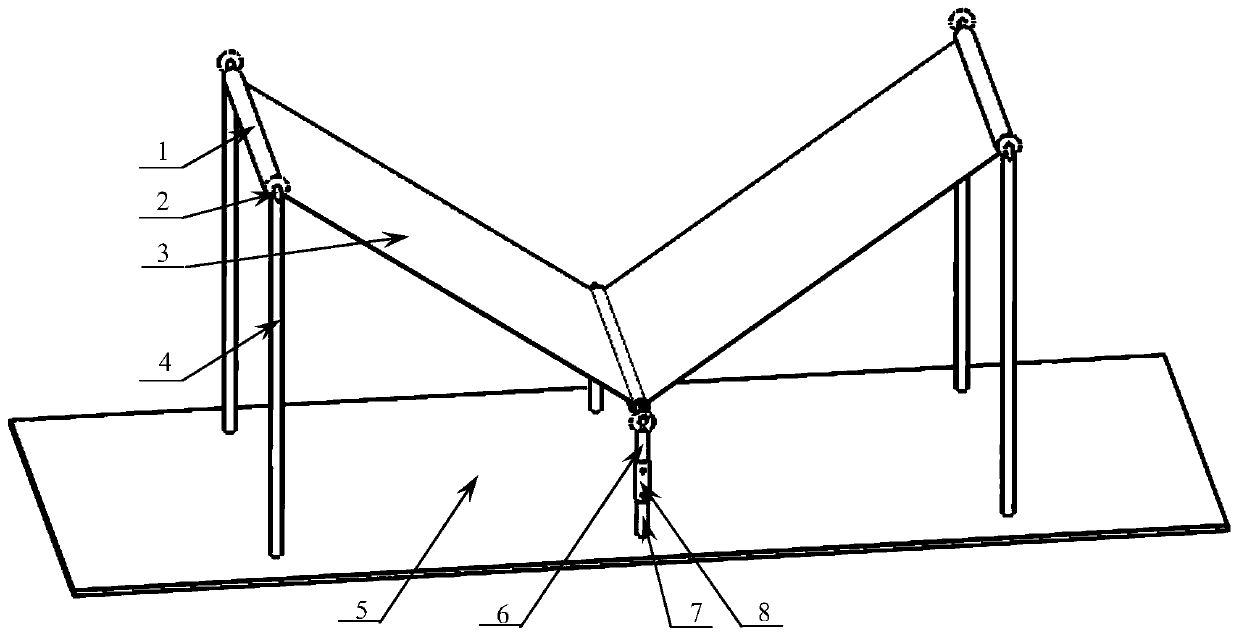

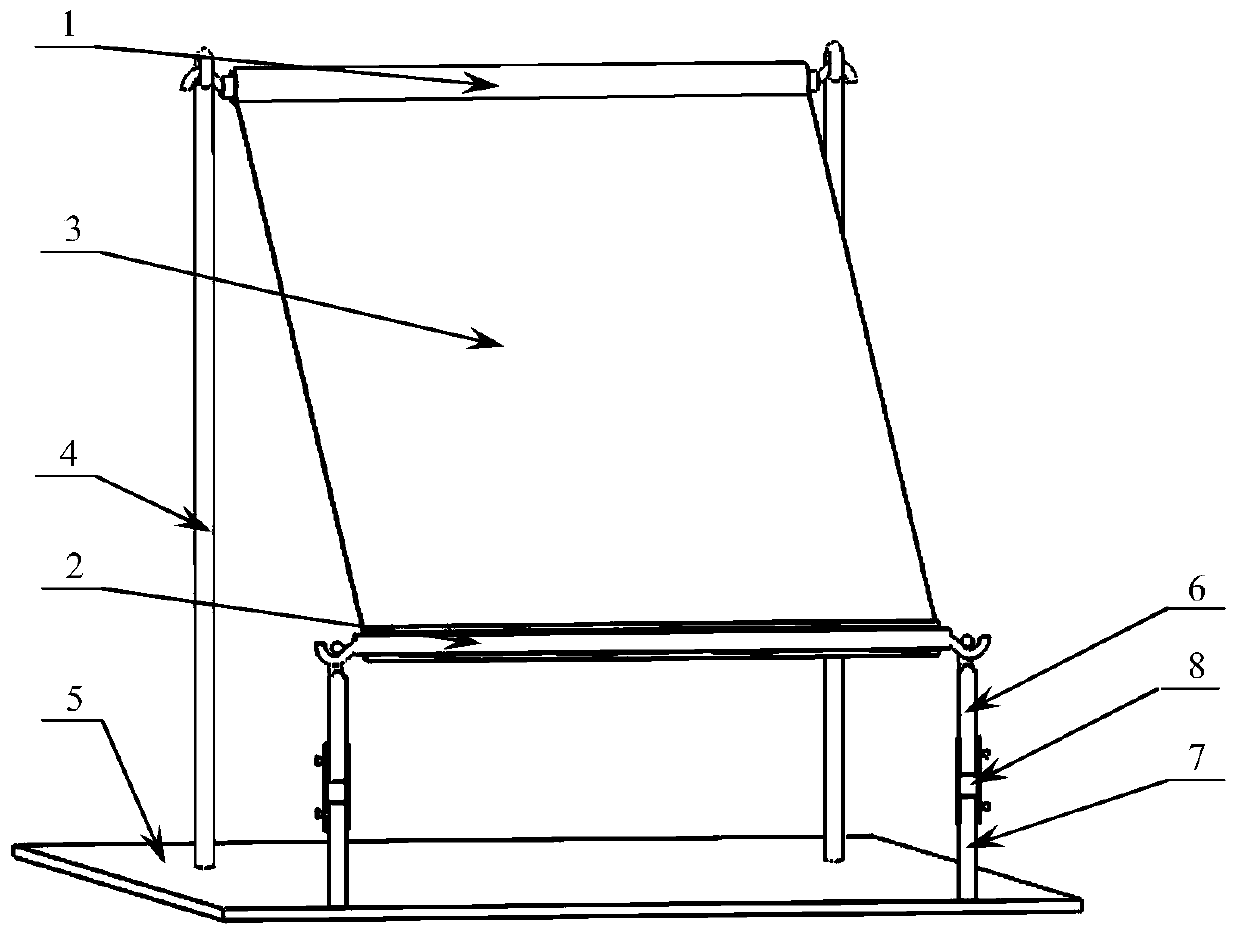

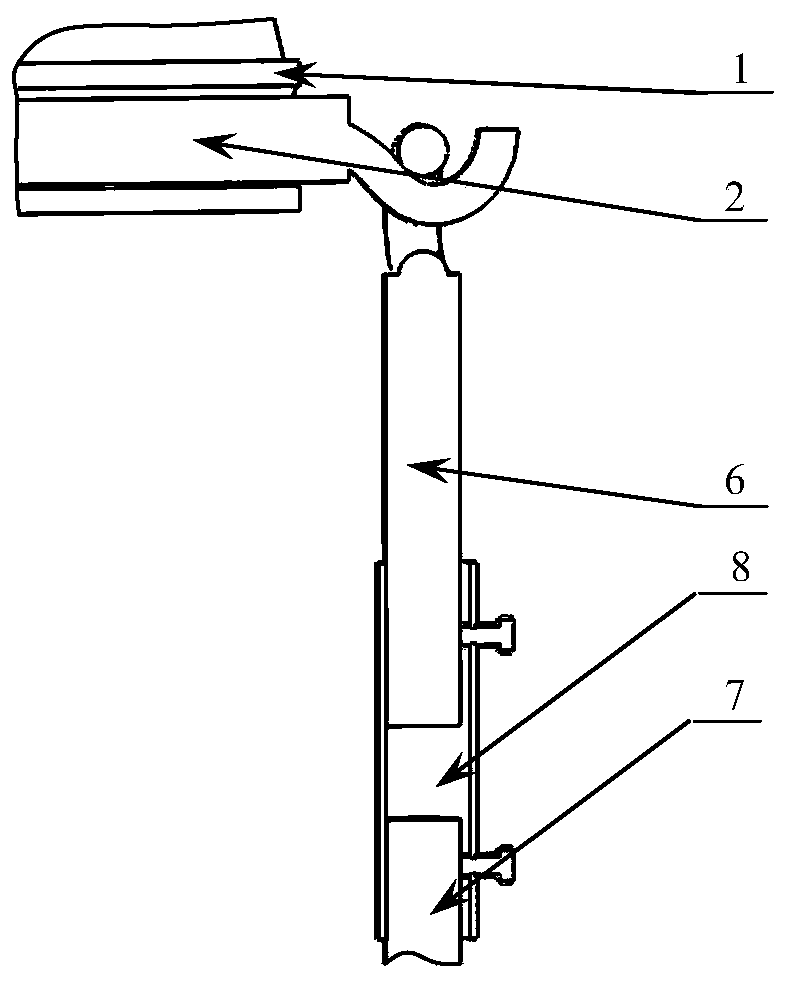

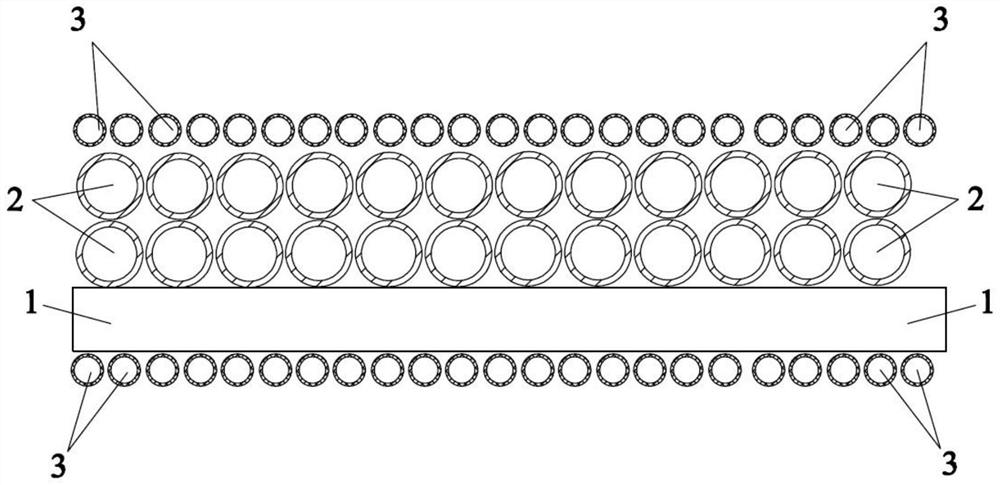

Vehicle-mounted road surface crack detection system detection device based on variable-depth cracks

The invention discloses a vehicle-mounted road surface crack detection system detection device based on the variable-depth cracks and aims at solving the checking problem of measurement results of different depths of cracks detected by a vehicle-mounted road surface crack detection system. The vehicle-mounted road surface crack detection system detection device based on the variable-depth cracks is mainly composed of rubber connecting pieces (1), cross bars (2), rubber (3), supports (4), a base (5), short supports (6), fixing shafts (7) and connecting pieces (8). The vehicle-mounted road surface crack detection system detection device based on the variable-depth cracks is provided and is variable in crack depth, simple in device structure, reliable in performance, easy and convenient to operate and install and low in cost.

Owner:JILIN UNIV

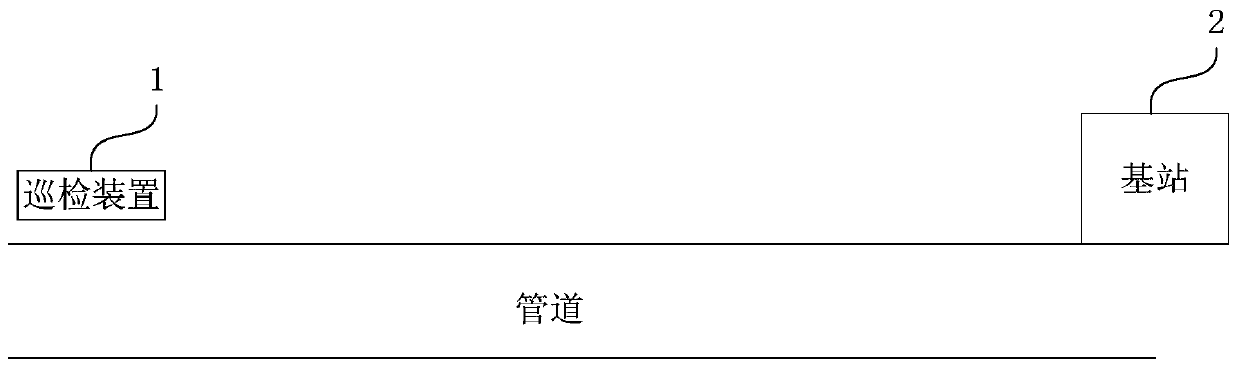

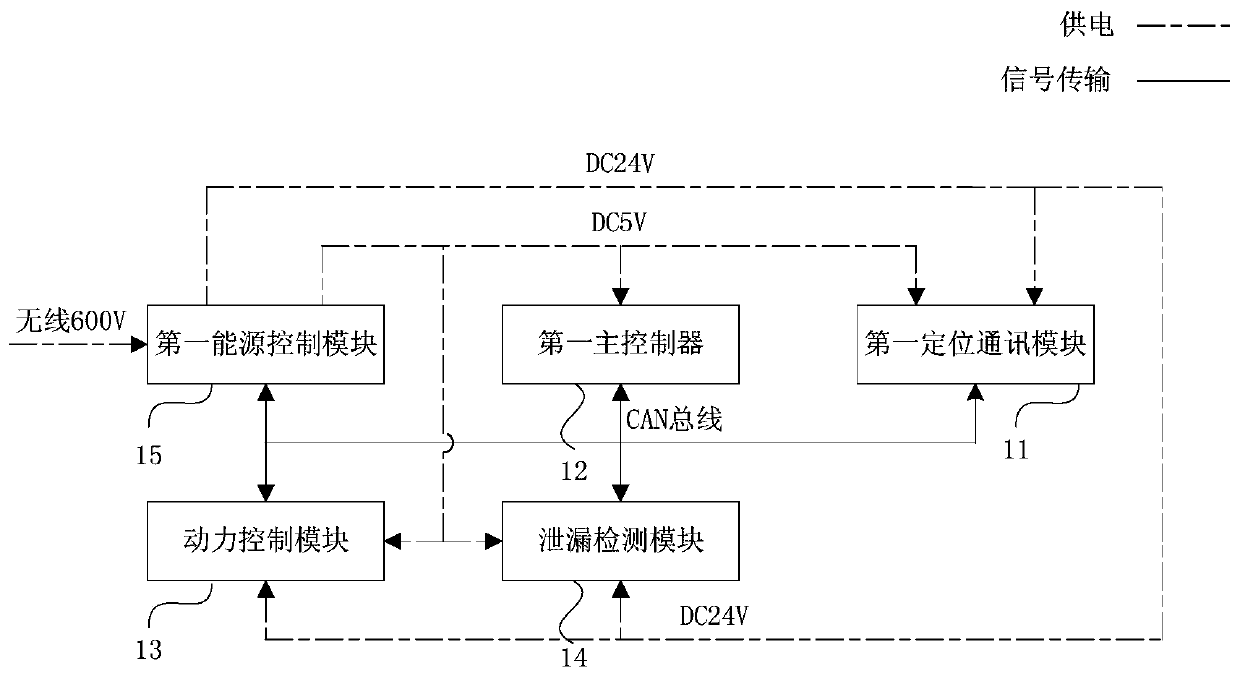

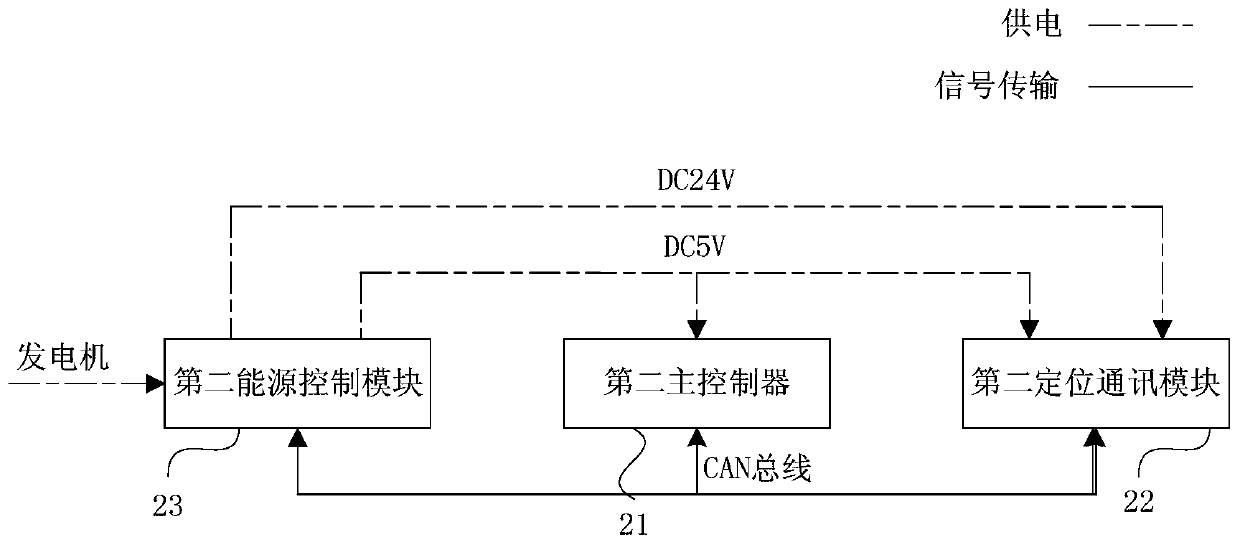

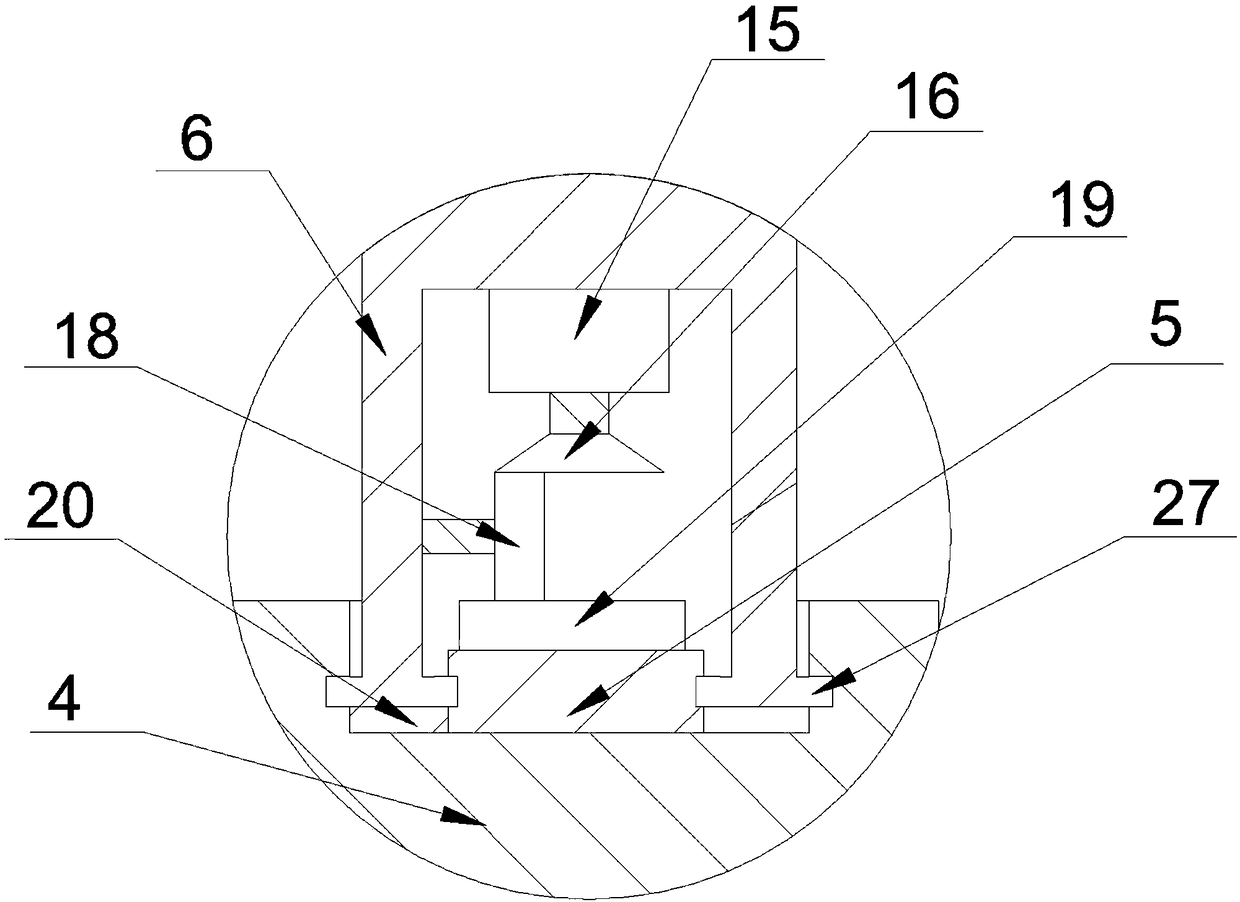

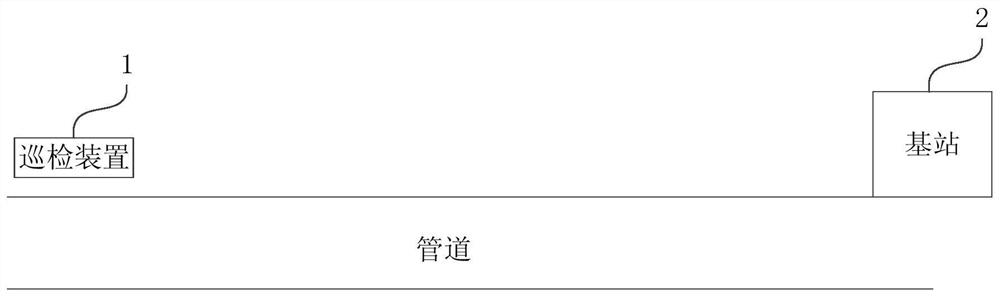

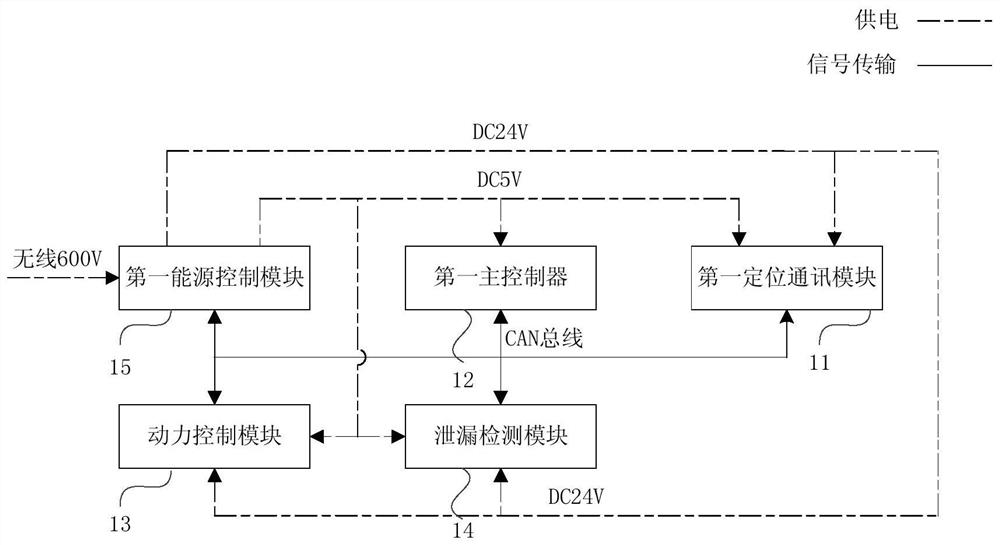

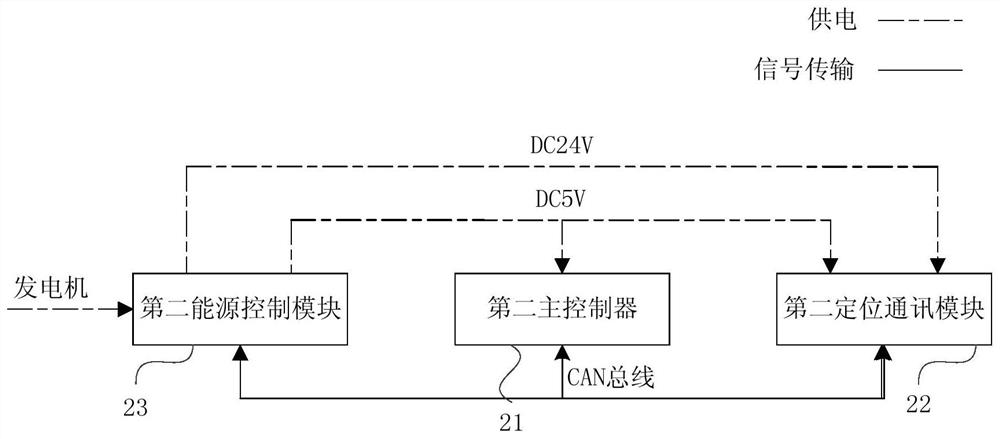

Underwater inspecting system

ActiveCN110005961ATo achieve the purpose of inspectionReduce lossesPosition fixationPipeline systemsUnderwaterAcoustic wave

The embodiment of the invention discloses an underwater inspecting system. The system comprises an inspecting device and a base station; the base station is arranged on a pipeline and used for transmission a positioning sonic wave signal to the inspecting device, and the inspecting device is used for receiving the positioning sonic wave signal and determining the relative position of a pipeline leakage point and the inspecting device according to the movement of the positioning sonic wave signal towards the base station and the real-time collection of the sonic wave signal of the pipeline leakage point in the moving process; the inspecting device is further used for transmitting a sonic wave signal requesting for charging, receiving an infrared signal to determine the moving direction towards a charging port of the base station based on the infrared signal, and butting with the charging port of the base station based on the moving direction to receive energy provided by the base station, and the base station is further used for transmitting the infrared signal to the inspecting device based on the sonic wave signal requesting for charging. The system has the advantages that the position of the pipeline leakage point can be rapidly and accurately positioned to reduce the loss of a pipeline transmission medium.

Owner:MEIZUAN SHENHAI ENERGY TECH RES & DEV SHANGHAI CO LTD

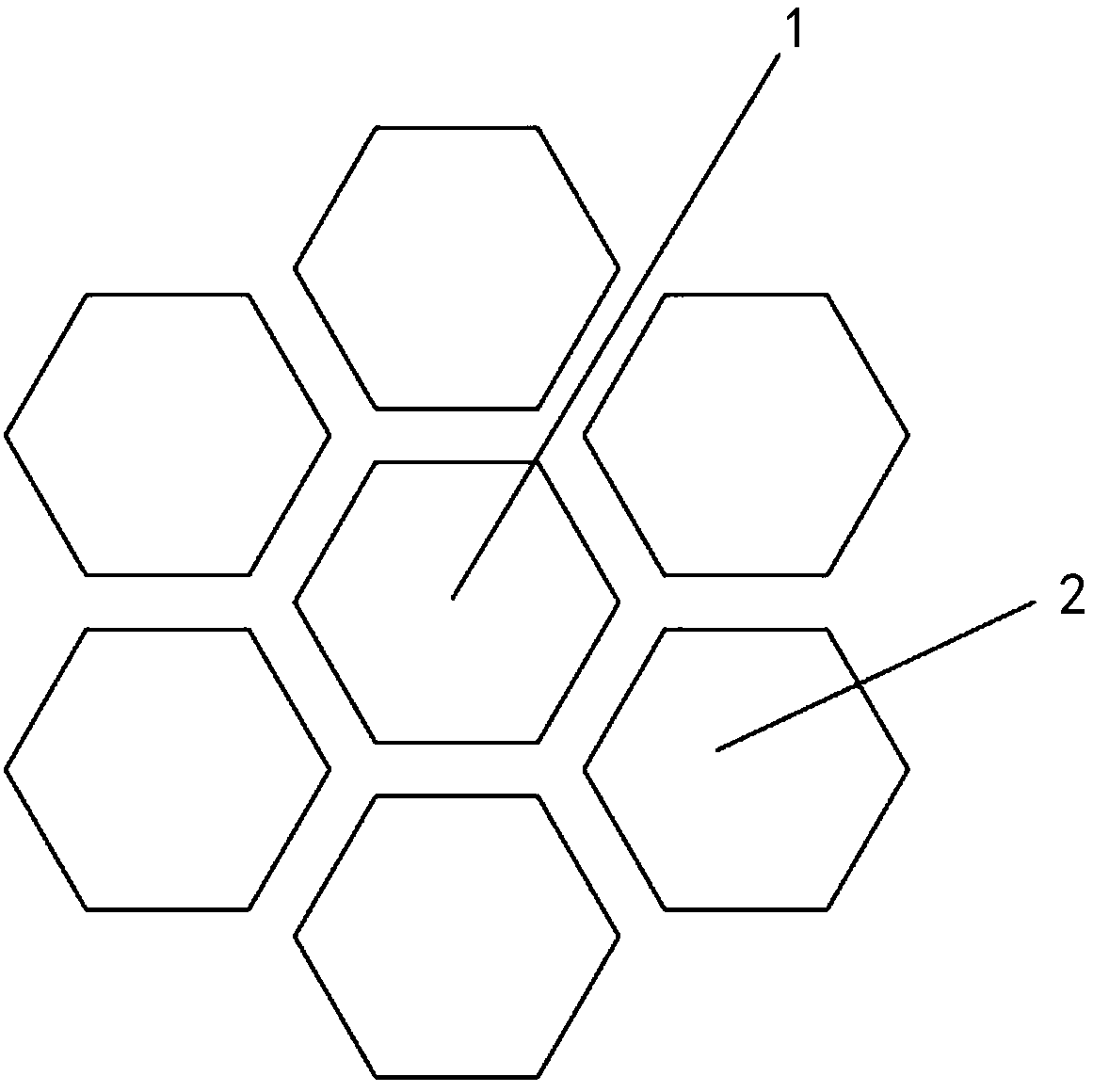

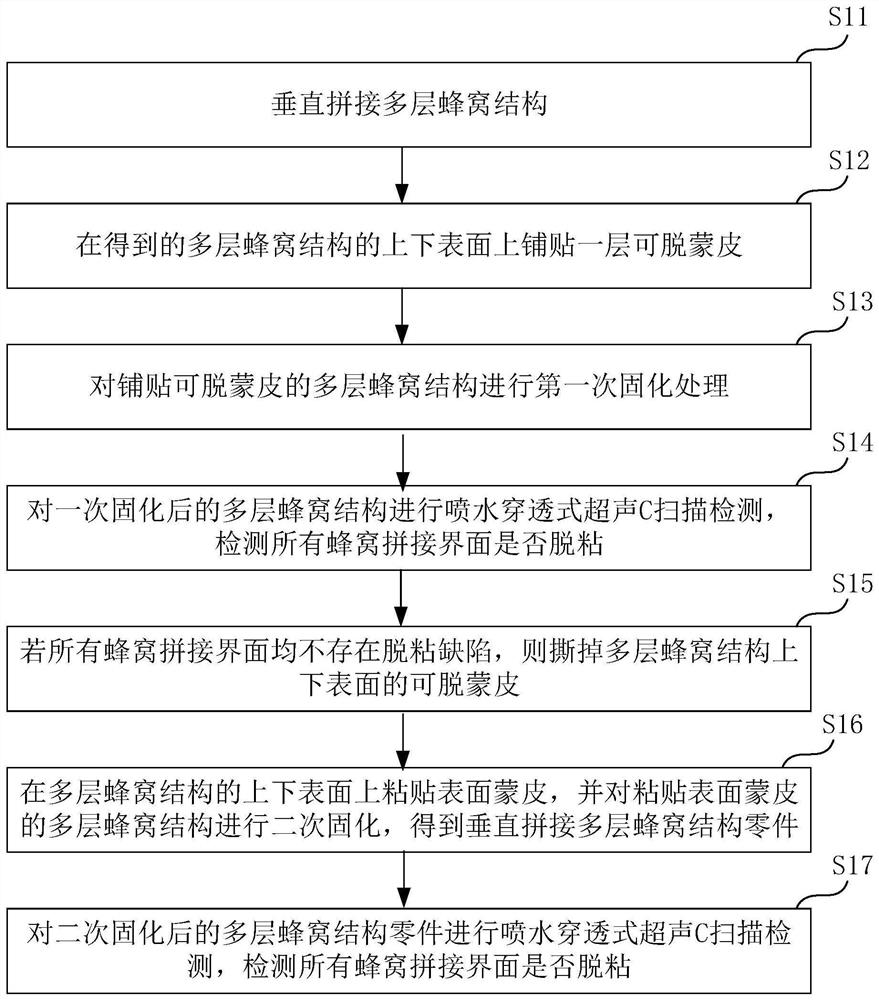

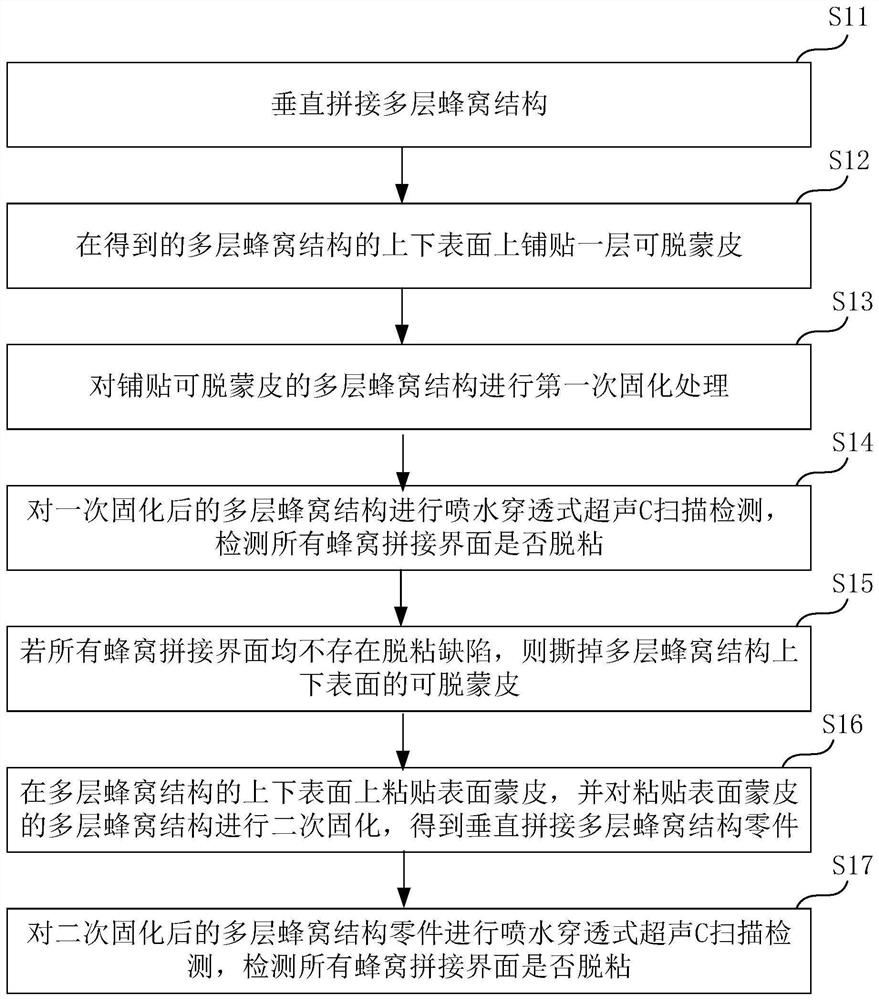

Vertical honeycomb splicing interface water-spraying penetration type ultrasonic detection method

ActiveCN112147217ATo achieve the purpose of inspectionBonding does not affectAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic testingHoneycomb structure

The invention discloses a vertical honeycomb splicing interface water-spraying penetration type ultrasonic detection method. The vertical honeycomb splicing interface water-spraying penetration type ultrasonic detection method comprises the following steps that a multilayer honeycomb structure is vertically spliced; a layer of detachable skin is paved and pasted on each of the upper surface and the lower surface of the obtained multilayer honeycomb structure; first curing treatment is conducted on the multilayer honeycomb structure paved with the detachable skin; water-spraying penetration type ultrasonic C scanning detection is conducted on the multilayer honeycomb structure subjected to primary curing, and whether all honeycomb splicing interfaces are debonded or not is detected; if allthe honeycomb splicing interfaces do not have the debonding defect, the detachable skins on the upper surface and the lower surface of the multilayer honeycomb structure are torn off; and surface skins are pasted to the upper surface and the lower surface of the multilayer honeycomb structure, secondary curing is conducted on the multilayer honeycomb structure pasted with the surface skins, and vertically-spliced multilayer honeycomb structure parts are obtained. According to the vertical honeycomb splicing interface water-spraying penetration type ultrasonic detection method, the quality of the vertically-spliced multilayer honeycomb sandwich structure part can be guaranteed, the scrap risk of the multilayer honeycomb sandwich structure part is reduced, and the production cost is saved advantageously.

Owner:COMAC +1

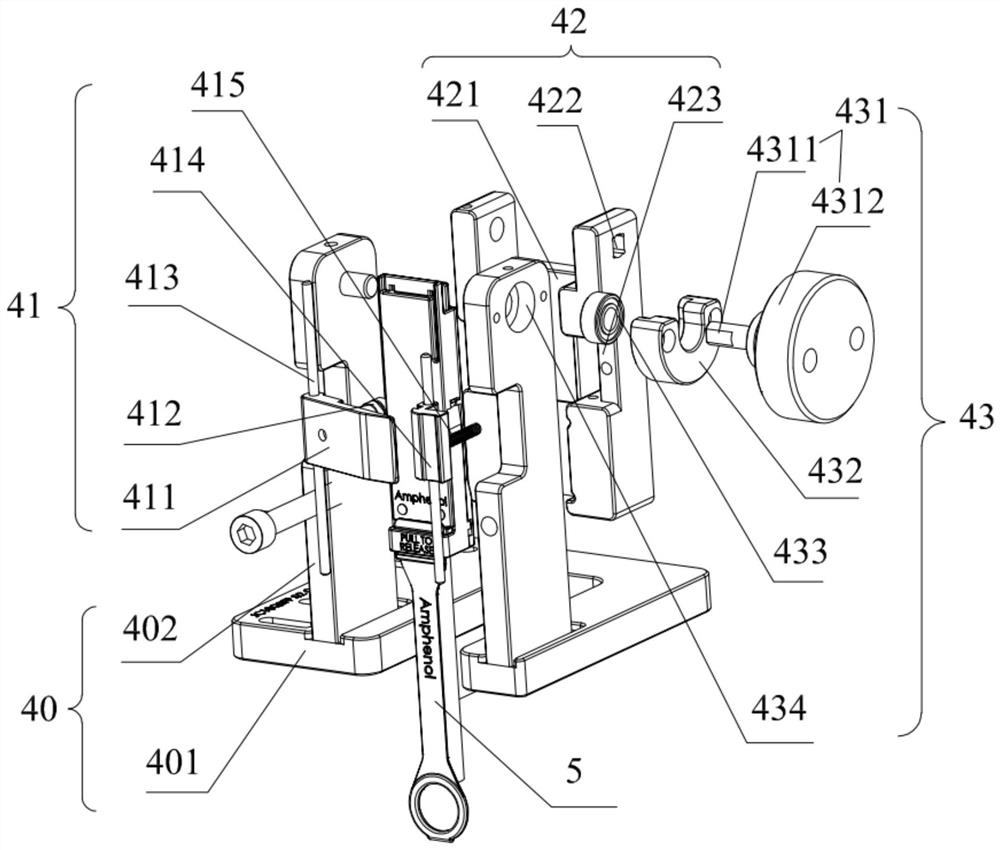

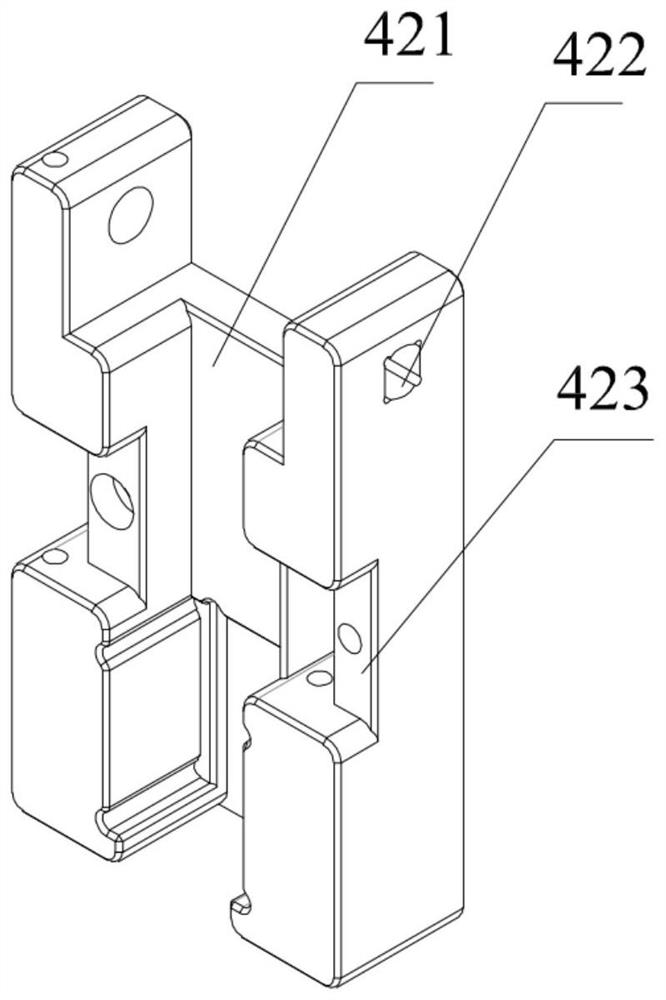

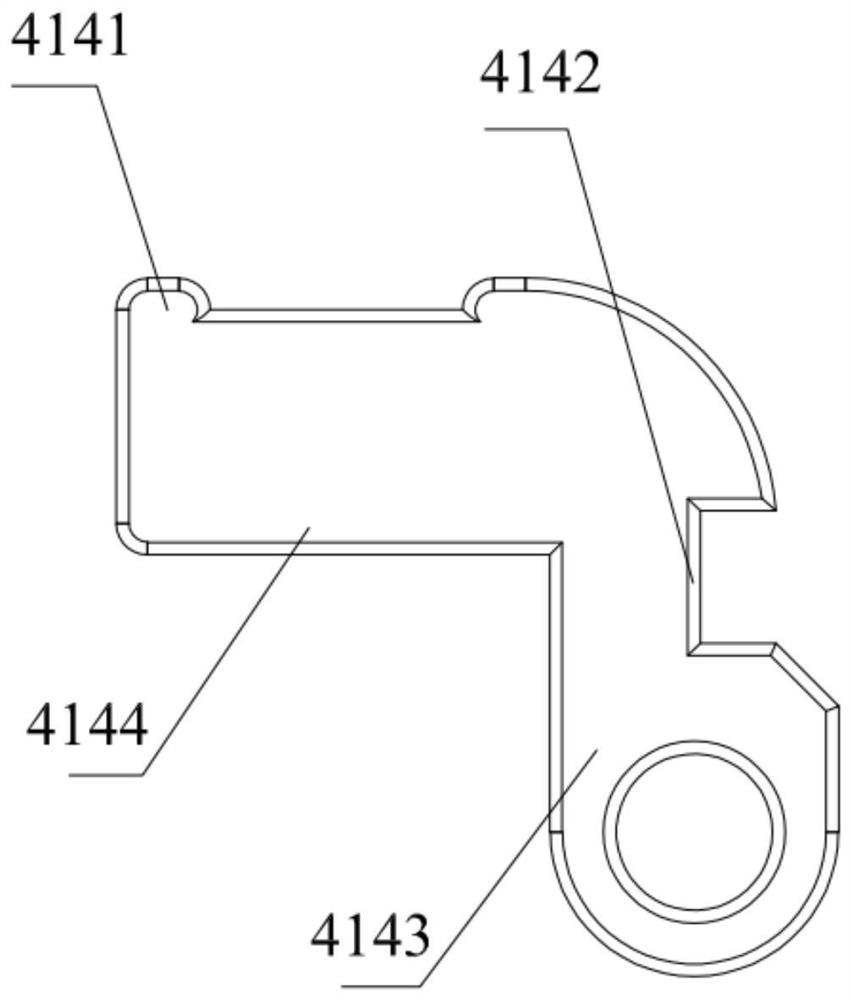

Wire harness connector PCB golden finger inspection equipment

PendingCN112540092AEfficient Stability CheckIncreased dirt efficiencyOptically investigating flaws/contaminationEngineeringWorkbench

The invention discloses wire harness connector PCB golden finger inspection equipment, and belongs to the field of machinery. The equipment comprises a workbench, a camera assembly, a wire harness connector wire clamping mechanism and a display. The camera assembly and the wire harness connector wire clamping mechanism are mounted on the workbench, the wire harness connector wire clamping mechanism is located at the position right opposite to a lens of the camera assembly, and the input end of the display is connected with the output end of the camera assembly. The beneficial effects of the invention are that the wire harness connector wire clamping mechanism is used to quickly fix a wire harness connector and cooperates with the camera assembly to achieve quick focusing and alignment, sothat a tedious focusing process is omitted, a golden finger on the wire harness connector can be imaged on the display quickly, and the purpose of efficient and stable inspection is achieved.

Owner:AMPHENOL (XIAMEN) HIGH SPEED CABLE CO LTD

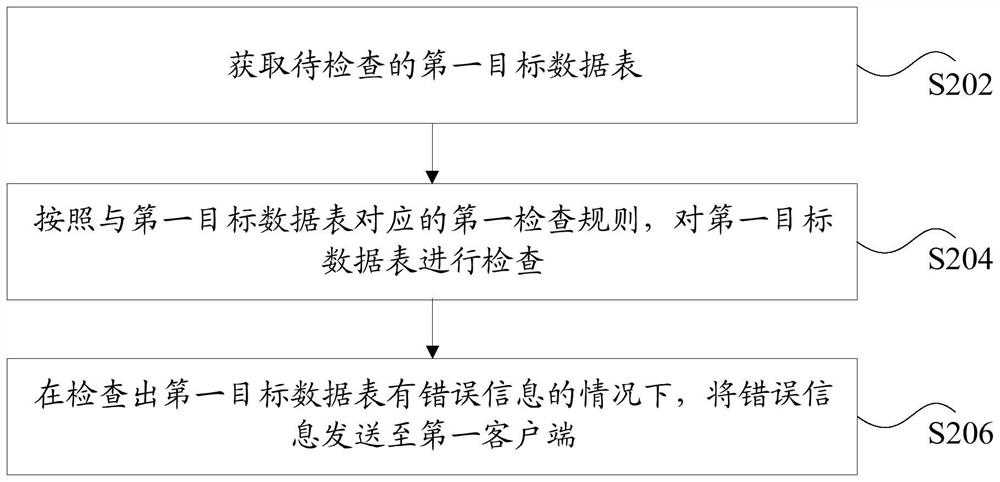

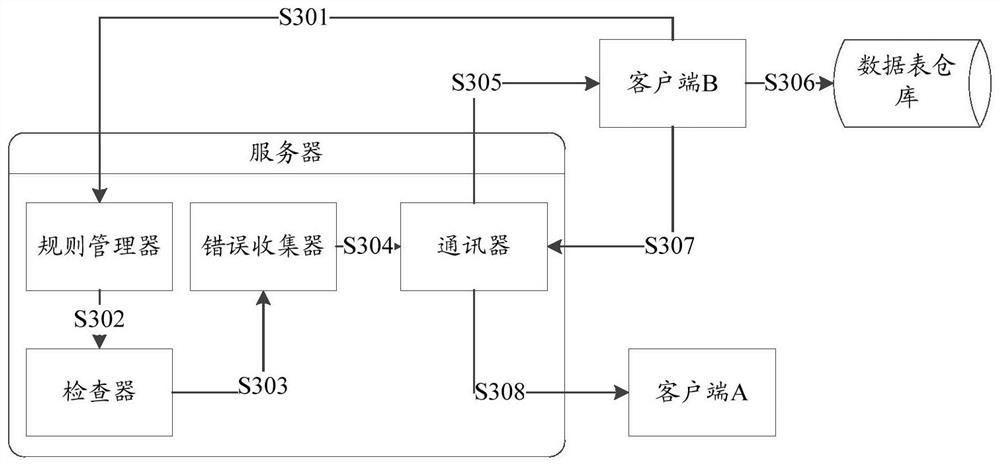

Data processing method, device, storage medium and electronic device

ActiveCN109446493BTo achieve the purpose of inspectionAvoid manual double checkingVersion controlText processingDatasheetData mining

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

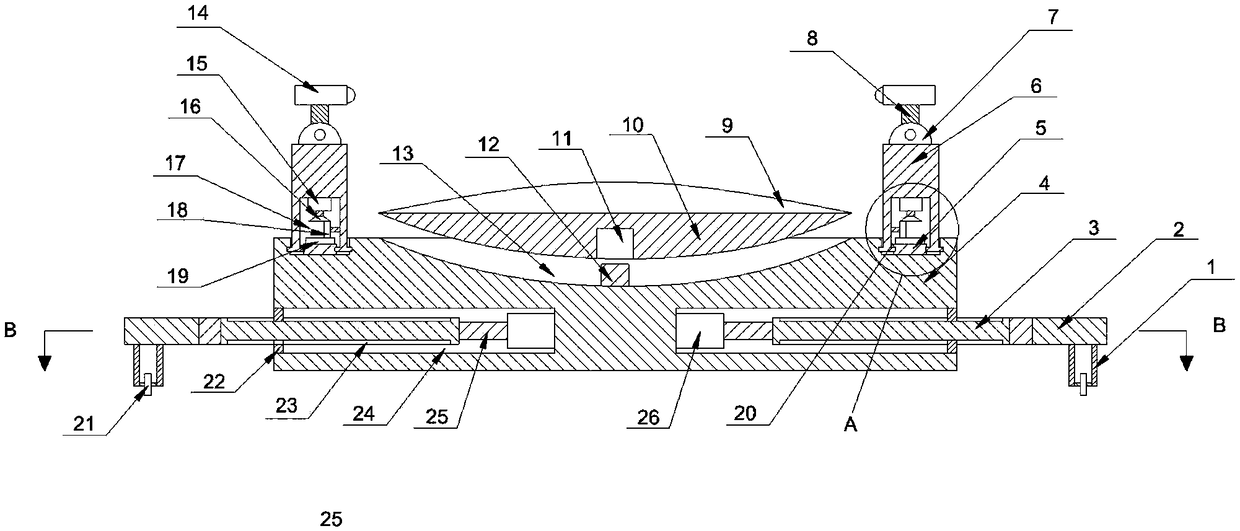

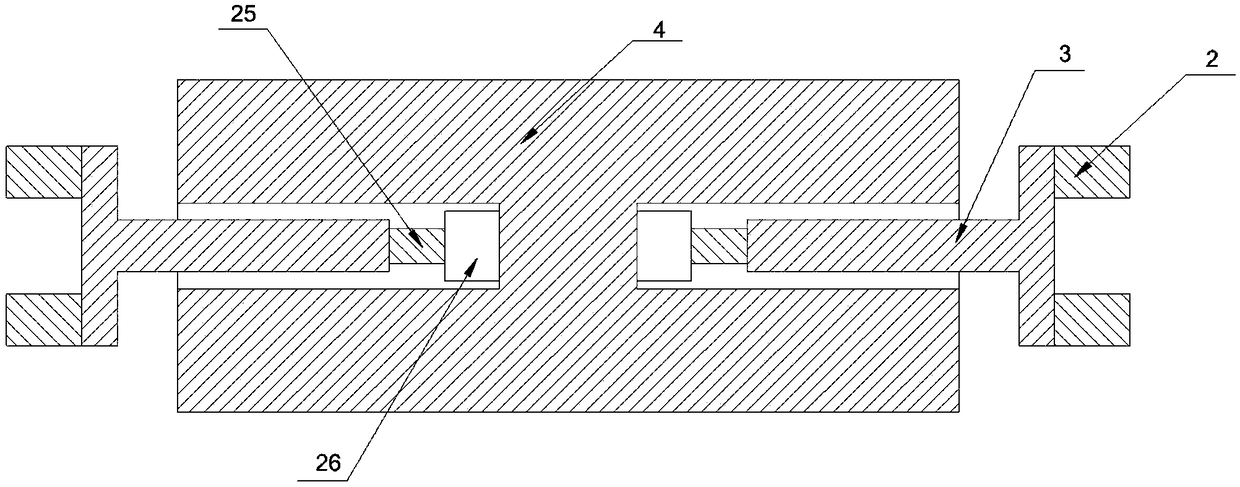

Vehicle-mounted pavement crack detection system inspection device based on variable depth cracks

InactiveCN108589490BRealize simulationRealize detectionMeasurement devicesRoads maintainenceEngineeringRoad surface

The invention discloses a vehicle-mounted road surface crack detection system detection device based on the variable-depth cracks and aims at solving the checking problem of measurement results of different depths of cracks detected by a vehicle-mounted road surface crack detection system. The vehicle-mounted road surface crack detection system detection device based on the variable-depth cracks is mainly composed of rubber connecting pieces (1), cross bars (2), rubber (3), supports (4), a base (5), short supports (6), fixing shafts (7) and connecting pieces (8). The vehicle-mounted road surface crack detection system detection device based on the variable-depth cracks is provided and is variable in crack depth, simple in device structure, reliable in performance, easy and convenient to operate and install and low in cost.

Owner:JILIN UNIV

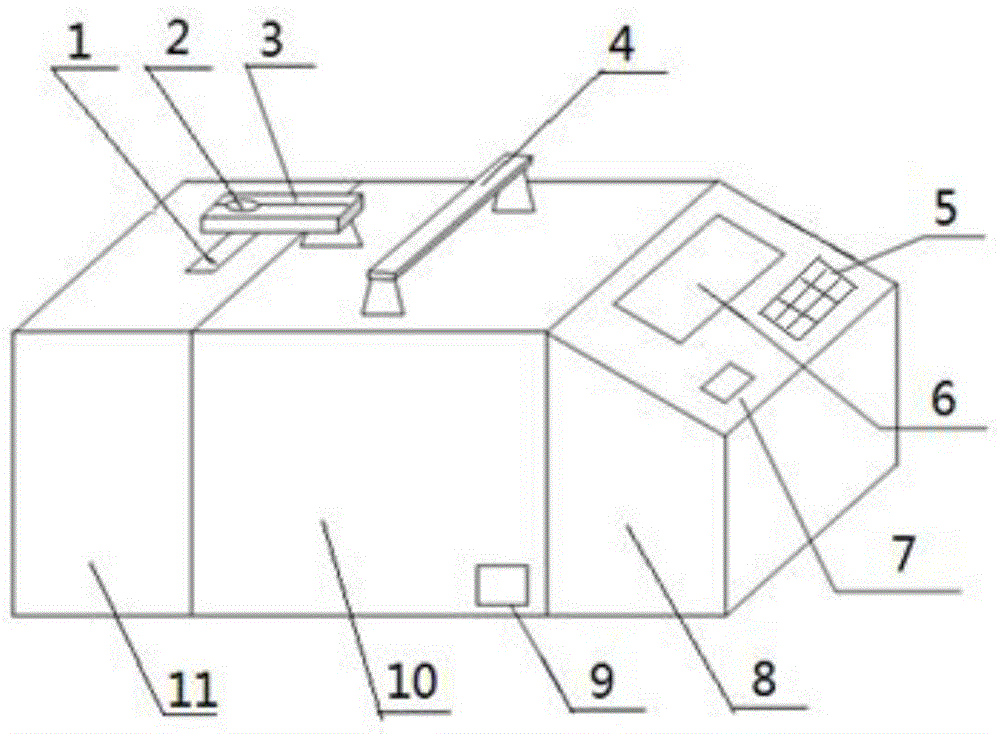

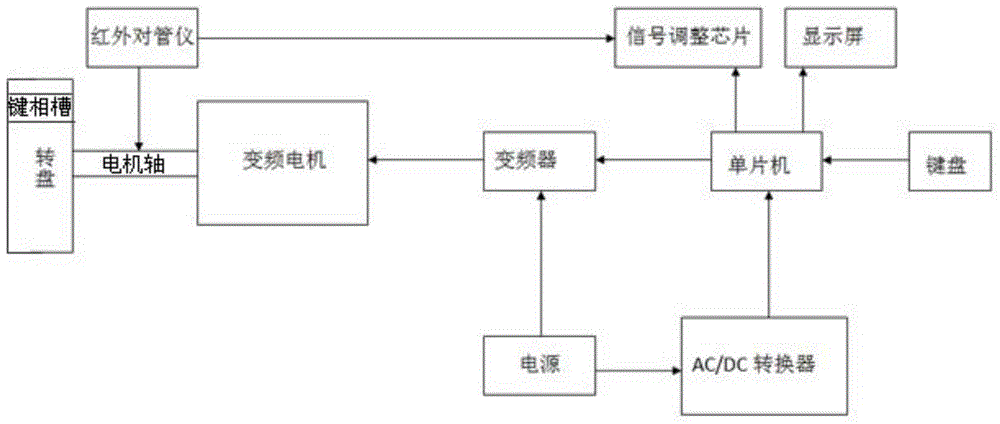

A speed sensor signal inspection device

ActiveCN104020315BGuarantee the need for normal and error-free workTo achieve the purpose of inspectionTesting/calibration of speed/acceleration/shock measurement devicesMicrocomputerAlternating current

The invention relates to a rotation speed sensor signal detection device, which comprises a handle, a power supply socket, a display screen, a button switch, a keyboard, a strip-shaped through hole and a sensor clip above the strip-shaped through hole which are arranged on the surface of the shell. The device also comprises a variable-frequency motor, a frequency converter, a single chip microcomputer, a signal adjusting chip, an infrared emitting diode and photodiode speed meter, an alternating current power supply and an AC / DC converter which are arranged inside the shell. A turntable is coaxially arranged on the left end head of the motor shaft; and the edge of the turntable is provided with an axial key phase groove. The invention creates a brand-new rotation speed sensor signal detection method, one hundred percent safe detection on the sensor can be realized in a physical quantity analog method, detection on working conditions of the sensor in different rotation speeds can be realized, the detection range is expanded, the detection ability is improved, and the detection data can be ensured to be fully and completely recorded.

Owner:STATE GRID CORP OF CHINA +1

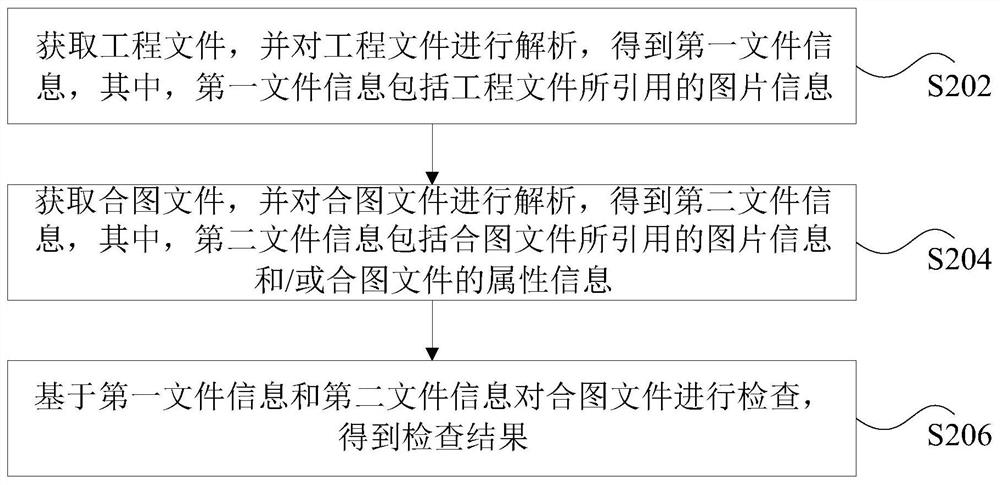

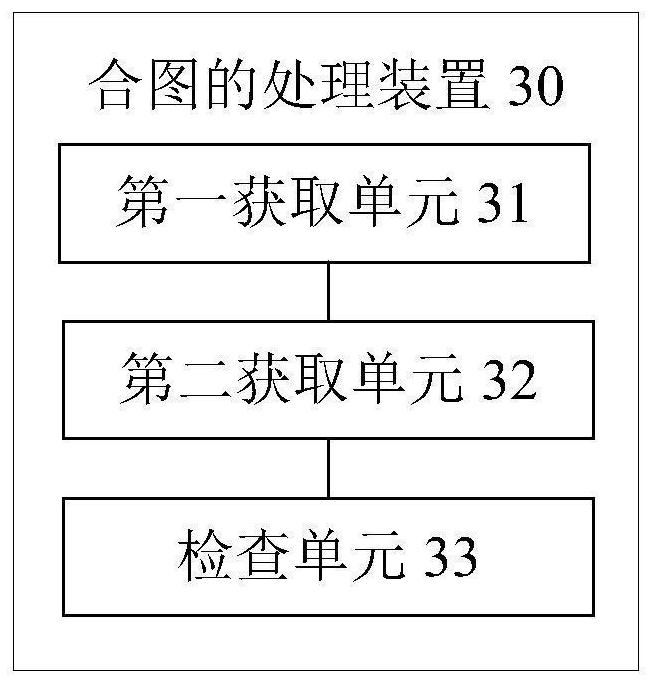

Combined image processing method and device, storage medium and electronic device

PendingCN111782607ASolve technical problems with low processing efficiencyImprove efficiencyAnimationFile metadata searchingImaging processingComputer graphics (images)

The invention discloses a combined image processing method and device, a storage medium and an electronic device. The method comprises the steps of acquiring and analyzing an engineering file to obtain first file information which comprises picture information cited by the engineering file; obtaining a picture combination file, and analyzing the picture combination file to obtain second file information which comprises picture information quoted by the picture combination file and / or attribute information of the picture combination file; and checking the combined image file based on the firstfile information and the second file information to obtain a checking result. According to the method and the device, the technical effects of checking a combined image and improving the combined image processing efficiency are achieved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Lithium ion battery diaphragm and preparation method thereof

InactiveCN113328204AIdentify dispersionTo achieve the purpose of inspectionLiquid surface applicatorsCell component detailsCeramic coatingPhysical chemistry

The invention belongs to the technical field of batteries, and particularly relates to a lithium ion battery diaphragm which comprises a base material and a coating arranged on the surface of the base material. The coating comprises a ceramic coating, a polymer coating or a ceramic and polymer mixed coating; at least one layer of ceramic coating is arranged on one surface of the base material, at least two layers of polymer coatings are respectively arranged on the surface of the ceramic coating and the other surface of the base material, or the ceramic polymer mixed coating is arranged on at least one surface of the base material, the ceramic coating is provided with a first coloring agent, the polymer coating is provided with a second coloring agent, and the ceramic polymer mixed coating is provided with a third coloring agent. The problem of coating missing of the lithium ion battery diaphragm can be solved, the consistency of the coating can be monitored, and the detection efficiency can be improved. In addition, the invention also discloses a preparation method of the lithium ion battery diaphragm.

Owner:HUIZHOU LIWINON ELECTRONIC TECH CO LTD

Power scheduling automatic inspection robot and inspection method based on crawler technology

ActiveCN104539053BRapid positioningQuick discoveryCircuit arrangementsTransmissionSimulationScript analysis

The invention discloses a power dispatching automation polling robot and method based on the reptile technology. The polling robot comprises a long-distance interface service module, a master control program module, a task module, a script analysis module, a polling uploaded data processing module, an abnormality management module and a running status monitoring module. The polling robot is based on the reptile technology, HTTP requests are simulated in an HTTP agency mode, an HttpClient and tmlParser open source assemblies are adopted for crawling links and key data of a service system needing to be monitored for the URL connection and interface analysis technologies, and automation polling on information systems is achieved. By means of the power dispatching automation polling robot and method, polling of a large number of the information systems can be carried out; the aim of polling in the script recording mode is achieved, the information system polling process is simplified, a large number of repeated manpower resources are released, and the work efficiency of dispatchers for polling the service system is improved.

Owner:STATE GRID CORP OF CHINA +3

Penetrating ultrasonic testing method of vertical honeycomb splicing interface with water spray

ActiveCN112147217BTo achieve the purpose of inspectionBonding does not affectAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic testingAcoustics

A vertical honeycomb splicing interface water spray penetrating ultrasonic detection method, comprising the following steps: vertically splicing multilayer honeycomb structures; paving a layer of peelable skin on the upper and lower surfaces of the obtained multilayer honeycomb structure; The multi-layer honeycomb structure that has been peeled off the skin is cured for the first time; the multi-layer honeycomb structure after the first curing is subjected to a water spray penetrating ultrasonic C-scan test to detect whether all the honeycomb splicing interfaces are debonded; if all the honeycomb splicing interfaces are If there is no debonding defect, the detachable skin on the upper and lower surfaces of the multi-layer honeycomb structure is torn off; the surface skin is pasted on the upper and lower surfaces of the multi-layer honeycomb structure, and the multi-layer honeycomb structure pasted with the surface skin is subjected to secondary curing , to obtain vertically spliced multilayer honeycomb structure parts. The above-mentioned ultrasonic testing method of vertical honeycomb splicing interface water spray penetrating can ensure the quality of the vertically spliced multilayer honeycomb sandwich structure parts, reduce the risk of scrapping the multilayer honeycomb sandwich structure parts, and help save production costs.

Owner:COMAC +1

A power inspection robot capable of crossing obstacles

ActiveCN110474253BLeapfrog realizationAcross smoothManipulatorApparatus for overhead lines/cablesInterference fitElectric machine

Owner:北京盛嘉鑫泰安装有限公司

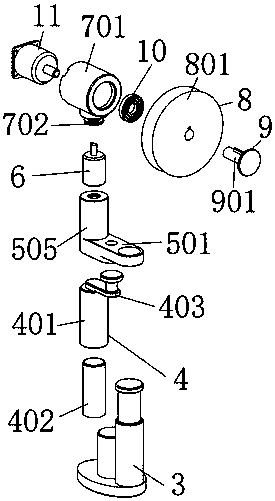

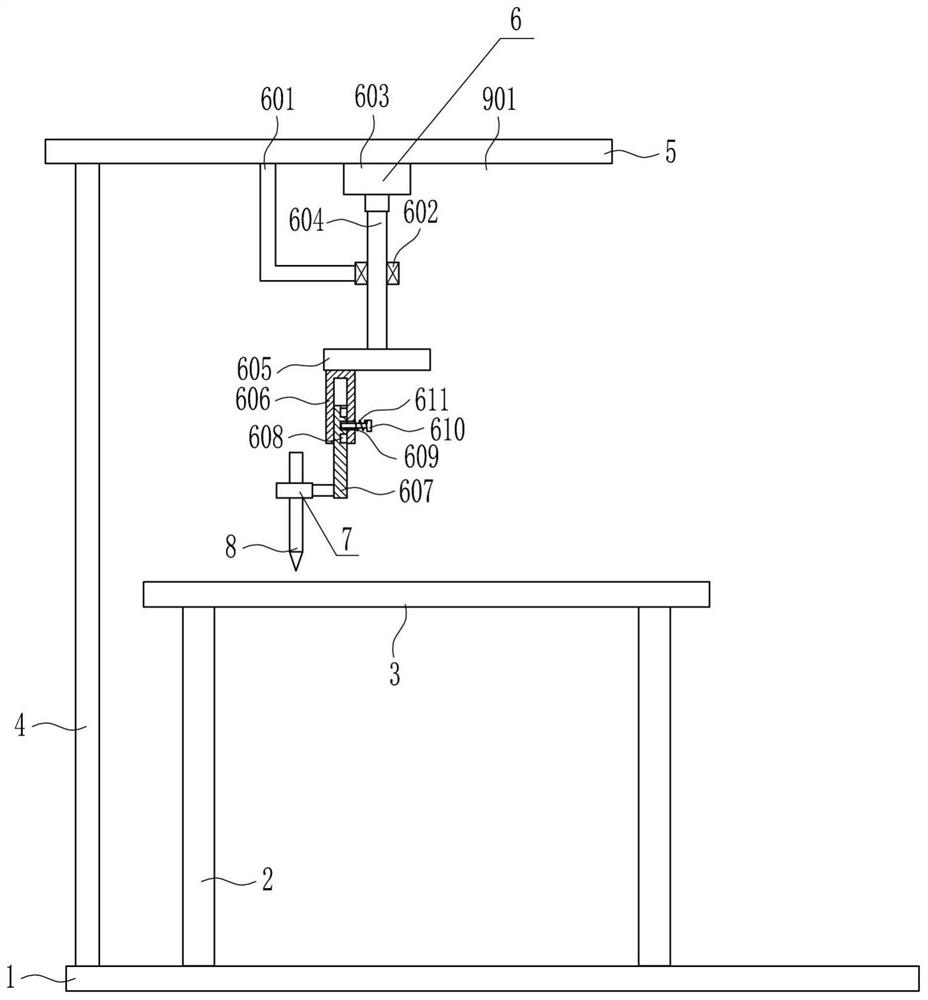

Coating effect inspection machine for electronic product mobile phone tempered film production

ActiveCN113075121ATo achieve the purpose of inspectionImprove inspection efficiencyUsing mechanical meansMaterial analysisMechanical engineeringMobile phone

The invention relates to a coating effect inspection machine for electronic product production, in particular to a coating effect inspection machine for electronic product mobile phone tempered film production. The technical problem to be solved by the invention is to provide the coating effect inspection machine for electronic product mobile phone tempered film production, which can save time and labor, improve the painting efficiency and improve the inspection efficiency of the coating effect of the mobile phone tempered film. In order to solve the technical problem, the invention provides the coating effect inspection machine for the electronic product mobile phone tempered film production, which comprises a bottom plate and the like, two supporting rods are vertically connected to the bottom plate, a containing plate is connected between the tops of the two supporting rods, and a supporting plate is vertically connected to the left side of the bottom plate and located on the left side of the containing plate. The fixing device rotates through the rotating device to drive the oily pen to rotate, and a circle can be drawn on the mobile phone tempered film, so that the purpose of inspecting the coating effect of the mobile phone tempered film is achieved, and the effect of saving time and labor is achieved.

Owner:江苏苏钏科技有限公司

Lower detection and inspection instrument for high-speed railway vehicle

InactiveCN109142372ARealize free expansionSolve operational problemsOptically investigating flaws/contaminationHand heldEngineering

The invention relates to an instrument for inspecting the bottom of a high-speed railway vehicle, in particular to a lower detection and inspection instrument for the high-speed railway vehicle. The instrument comprises a detection and inspection instrument main body, a convex mirror with a mirror seat is arranged above the detection and inspection instrument main body, a searchlight is connectedwith the upper surface of the detection and inspection instrument main body, outside of the convex mirror, through a rotating mechanism, first cavities are symmetrically arranged at the lower part inthe detection and inspection instrument main body; a telescopic mechanism is arranged in each first cavity; the longitudinal parts of T-shaped sliding rods of the telescopic mechanisms are in slidingfit with the cavities; the transverse parts of the T-shaped sliding rods are arranged outside the first cavities in parallel with the upper surface of the detection and inspection main body; the two ends of the transverse parts, away from the end surface of the detection and inspection main body, are both provided with a sliding mechanism for detecting the sliding of the detection and inspection main body. According to the invention, the instruments solves the problems of difficult operation by using a hand-held handle and a long detection and maintenance time period when a prior lower detection and inspection instrument for the high-speed railway vehicle is in use.

Owner:西安安源智造机电设备有限公司

Underwater inspection system

ActiveCN110005961BTo achieve the purpose of inspectionReduce lossesPosition fixationPipeline systemsUnderwaterEngineering

The embodiment of the invention discloses an underwater inspecting system. The system comprises an inspecting device and a base station; the base station is arranged on a pipeline and used for transmission a positioning sonic wave signal to the inspecting device, and the inspecting device is used for receiving the positioning sonic wave signal and determining the relative position of a pipeline leakage point and the inspecting device according to the movement of the positioning sonic wave signal towards the base station and the real-time collection of the sonic wave signal of the pipeline leakage point in the moving process; the inspecting device is further used for transmitting a sonic wave signal requesting for charging, receiving an infrared signal to determine the moving direction towards a charging port of the base station based on the infrared signal, and butting with the charging port of the base station based on the moving direction to receive energy provided by the base station, and the base station is further used for transmitting the infrared signal to the inspecting device based on the sonic wave signal requesting for charging. The system has the advantages that the position of the pipeline leakage point can be rapidly and accurately positioned to reduce the loss of a pipeline transmission medium.

Owner:MEIZUAN SHENHAI ENERGY TECH RES & DEV SHANGHAI CO LTD

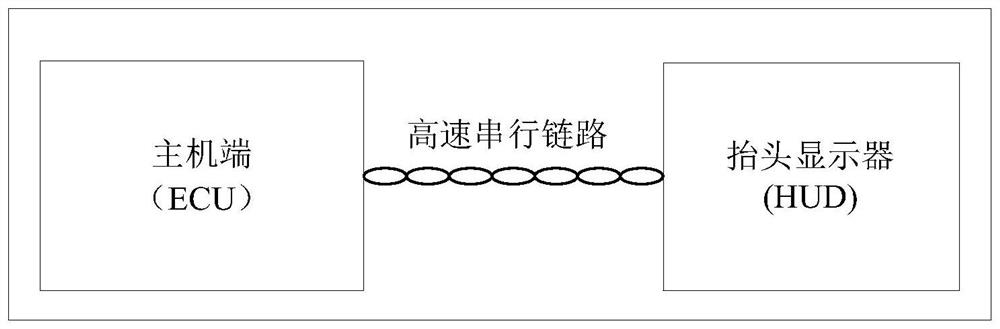

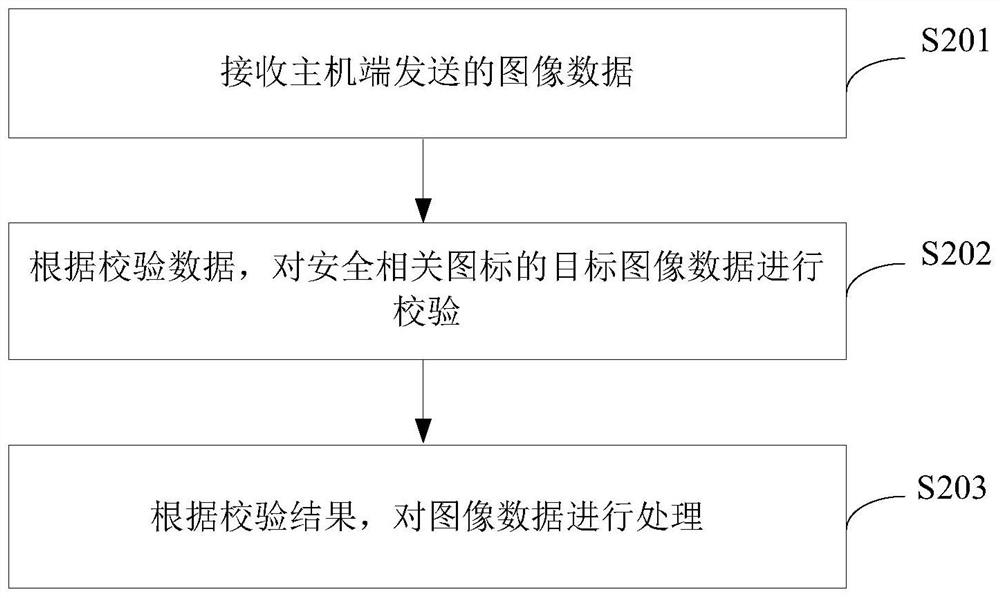

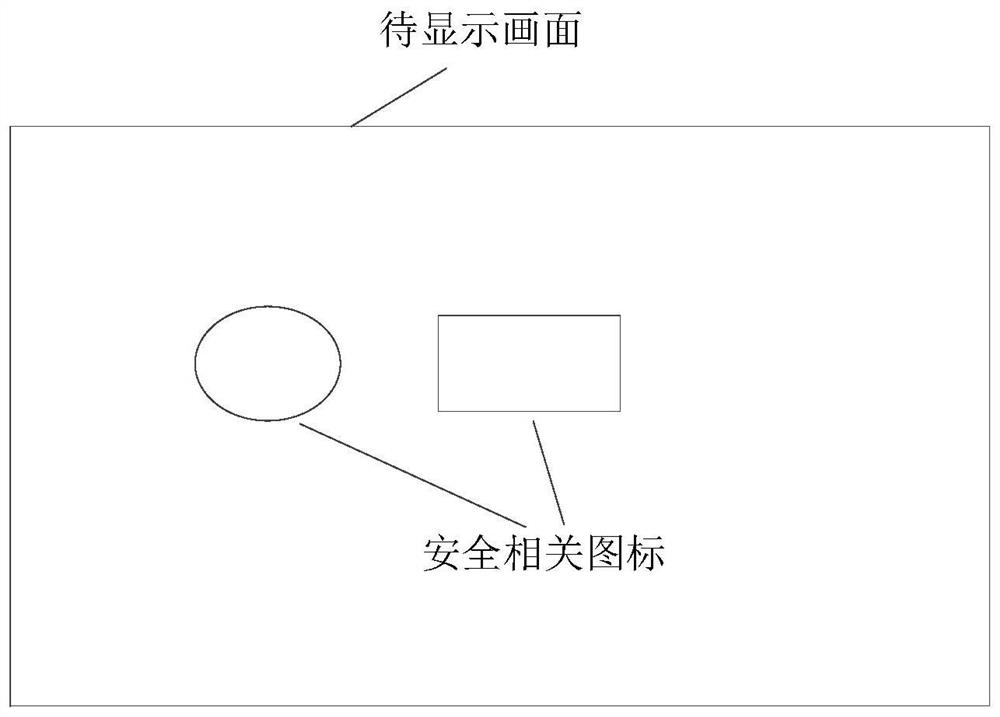

Data processing method and device, head-up display and storage medium

ActiveCN114818009AImprove driving safetyTo achieve the purpose of inspectionDigital data protectionOptical elementsData displayData pack

The embodiment of the invention provides a data processing method and device, a head-up display and a storage medium, and the method comprises the steps: receiving image data sent by a host end, the image data comprises effective display data and verification data, the image data is data of a to-be-displayed picture, and the to-be-displayed picture comprises a safety related icon; according to the verification data, verifying the target image data of the security related icon in the effective display data; and processing the image data according to the verification result. By setting the verification data to verify the data of the safety-related icons in the image data before controlling the display of the image data, the purpose of verifying the content of the image data is achieved on the premise of not increasing hardware cost, the display accuracy of the safety-related icons is ensured, and the driving safety of a user is improved.

Owner:泽景(西安)汽车电子有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com