Detection system for large-sized panel display device

A flat-panel display and detection system technology, which is applied in the direction of machine/structural component testing, instrumentation, measuring electricity, etc., to reduce damage and scratches, improve accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

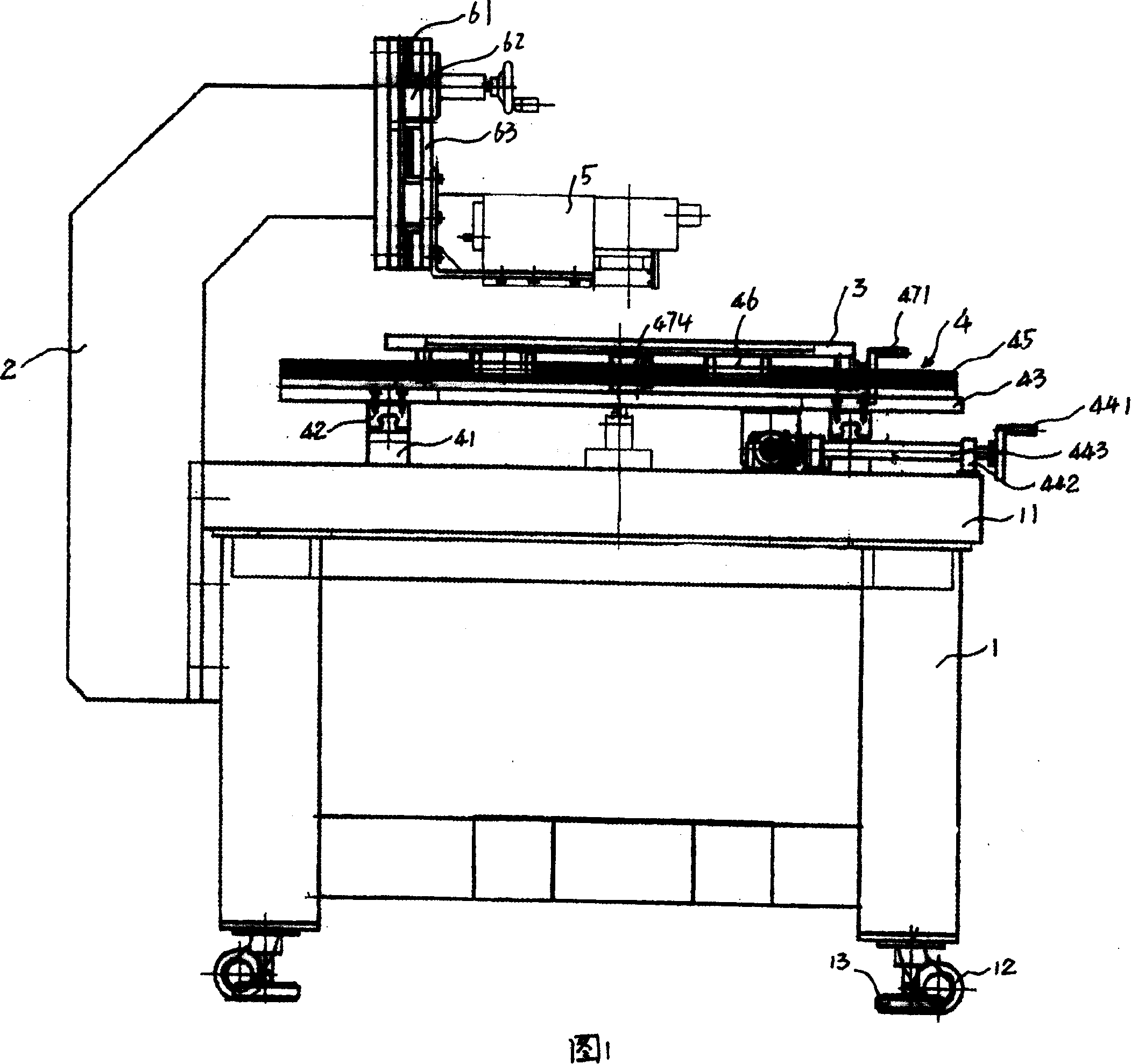

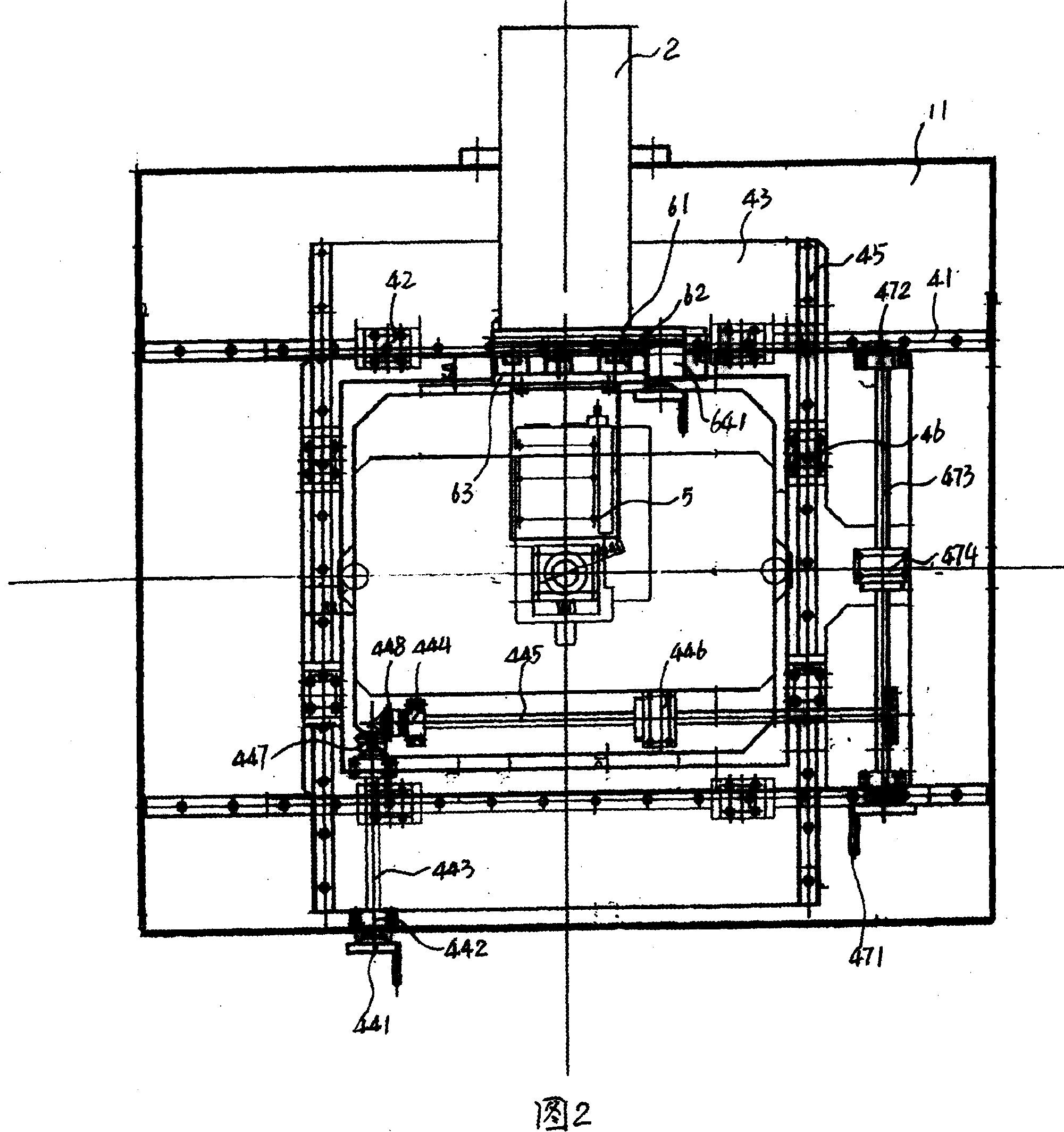

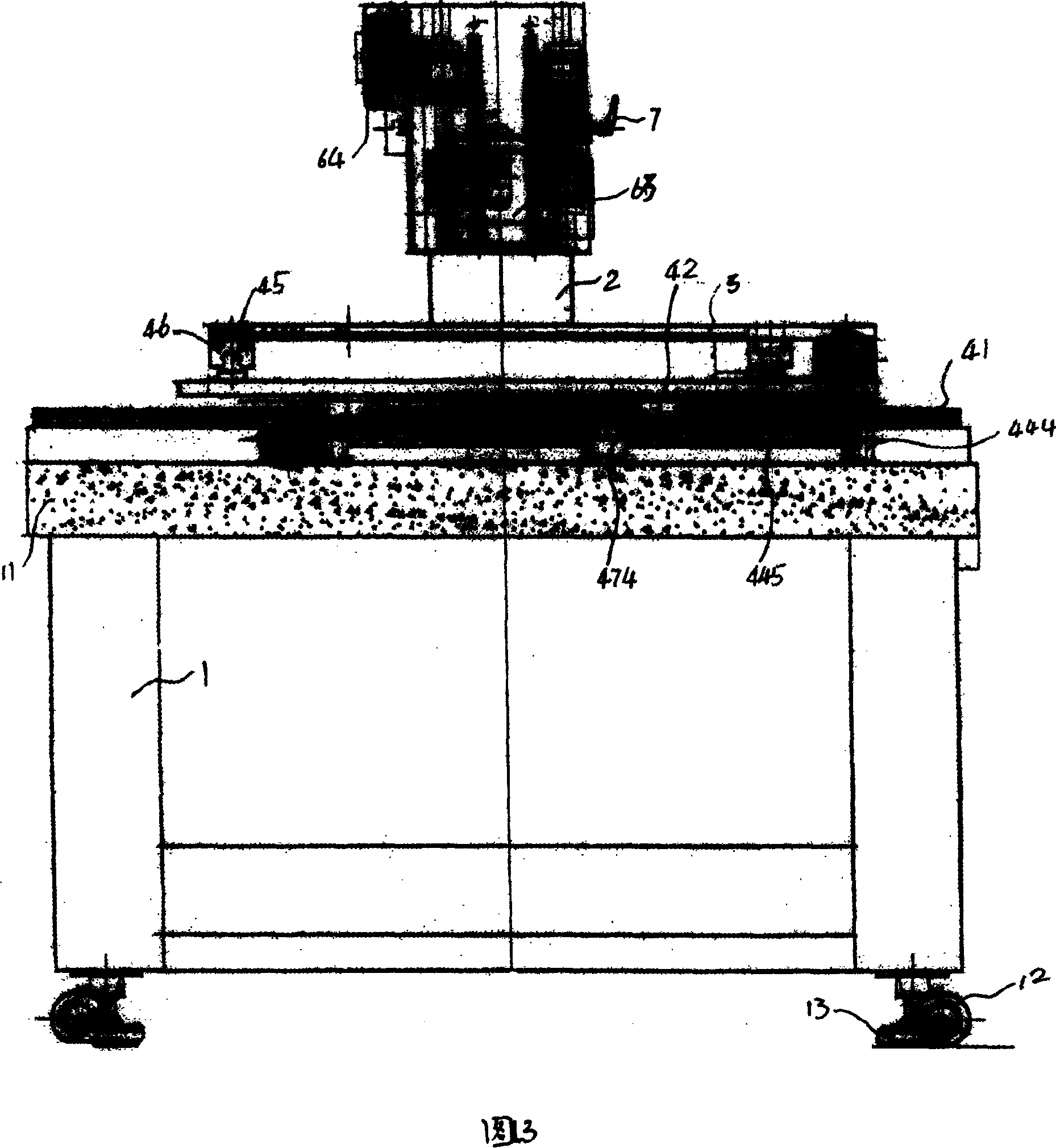

[0038] Referring to Fig. 1 and Fig. 2, the large-scale flat-panel display detection system includes: a machine base 1, the machine base platform 11 of the machine base 1 is made of granite, and universal wheels 12 and positioning adjustment are installed on the bottom of the machine base 1 Wheel 13, universal wheel 12 can make support 1 move conveniently, and when support 1 moves to specified position, rotation location adjustment wheel 13 just can make moving support 1 location and to adjust the horizontal position of support 1. This can reduce the shaking of the machine base 1 during the detection process. Of course, the positioning adjustment wheel 13 can also be adjusted in a telescopic manner.

[0039] On the rear side of the support 1, a reverse L-shaped machine head 2 extending upwards is fixedly installed by fasteners.

[0040] The mobile platform 3 is installed on the base platform 11 through a mobile device 4 capable of moving in the X-Y direction. The mobile devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com