Electrified cleaning insulating maintenance robot device for high-voltage power equipment

A technology of high-voltage power equipment and robots, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve problems such as low safety performance, large driving force, instability, etc., and achieve accurate detection. , The effect of stable lifting, stability and precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

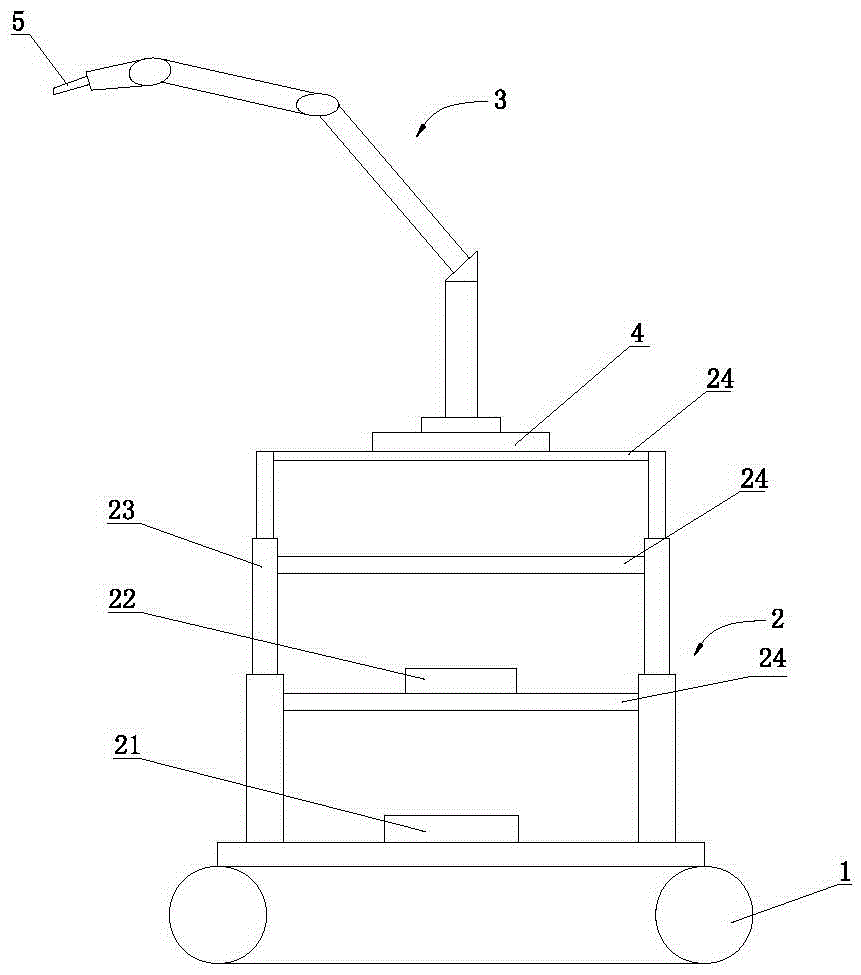

[0024] Such as figure 1 As shown, the live cleaning and insulation care robot device for high-voltage power equipment includes a traveling mechanism 1 , a lifting mechanism 2 , a cleaning and insulation care robot arm 3 and a remote control steering control unit 4 .

[0025] The traveling mechanism 1 is a crawler-type traveling mechanism or a wheel-type traveling mechanism.

[0026] The running mechanism 1 is provided with a power motor to drive the steering gear, a first rechargeable lithium battery, a first microprocessor circuit, a first Zig-bee communication module and a first miniature antenna, and the power motor drives the steering gear to drive the running gear. The rechargeable lithium battery is electrically connected with the power motor-driven steering gear and the first microprocessor circuit, the first is that the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com