A speed sensor signal inspection device

A technology of speed sensor and inspection device, which is applied to measuring devices, instruments, speed/acceleration/shock measurement, etc., which can solve the problems of not being able to know the working status of the probe, low frequency of hand shaking, and personnel fatigue, and achieve quick disassembly and adjustment Distance, easy to adjust the distance, to ensure the effect of complete recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0021] Invention idea

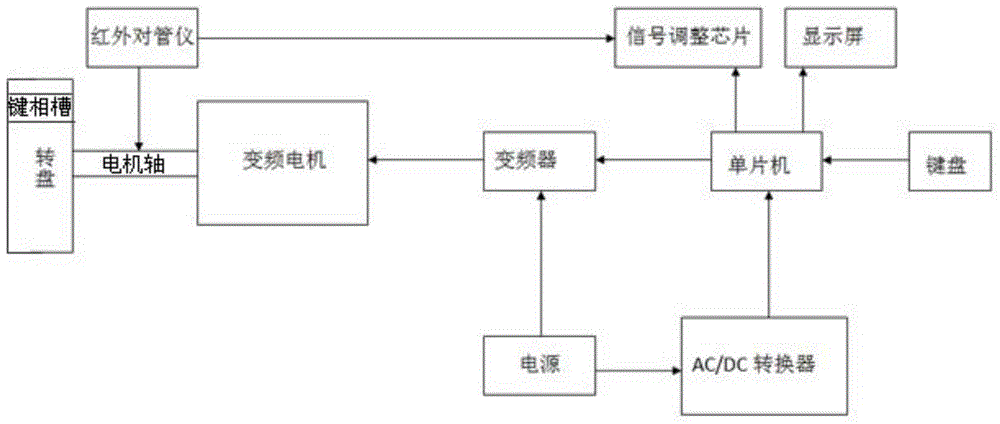

[0022] The basic principle of the invention is to simulate the rotation of the rotating shaft of the rotating machine, and trigger the sensor with the real physical rotational speed to check whether the signal channel is smooth or not and the working stability of the device.

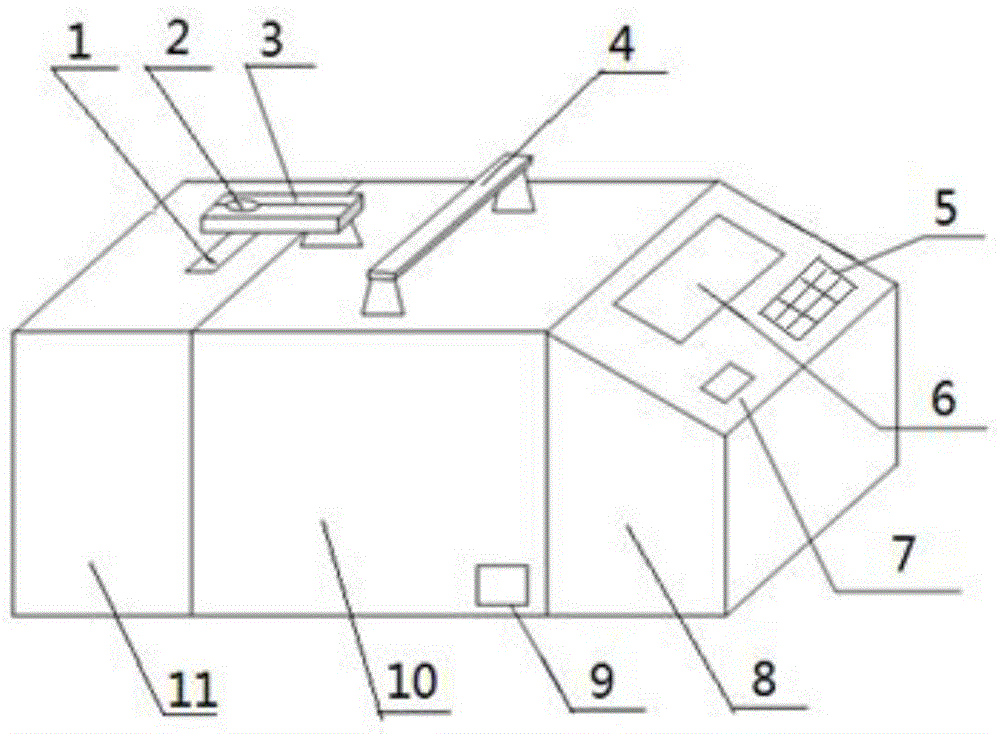

[0023] A speed sensor signal inspection device, such as figure 1 As shown, the device housing is included, and the housing is divided into a left housing 11, a middle housing 10 and a right housing 8, and a handle 4 is installed on the upper surface of the middle housing to facilitate the movement of the device. A power socket 9 is fixedly installed on the front side wall of the middle part housing, a display scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com